Batch management optimizes item-specific storage and tracking of goods using a unique lot number.

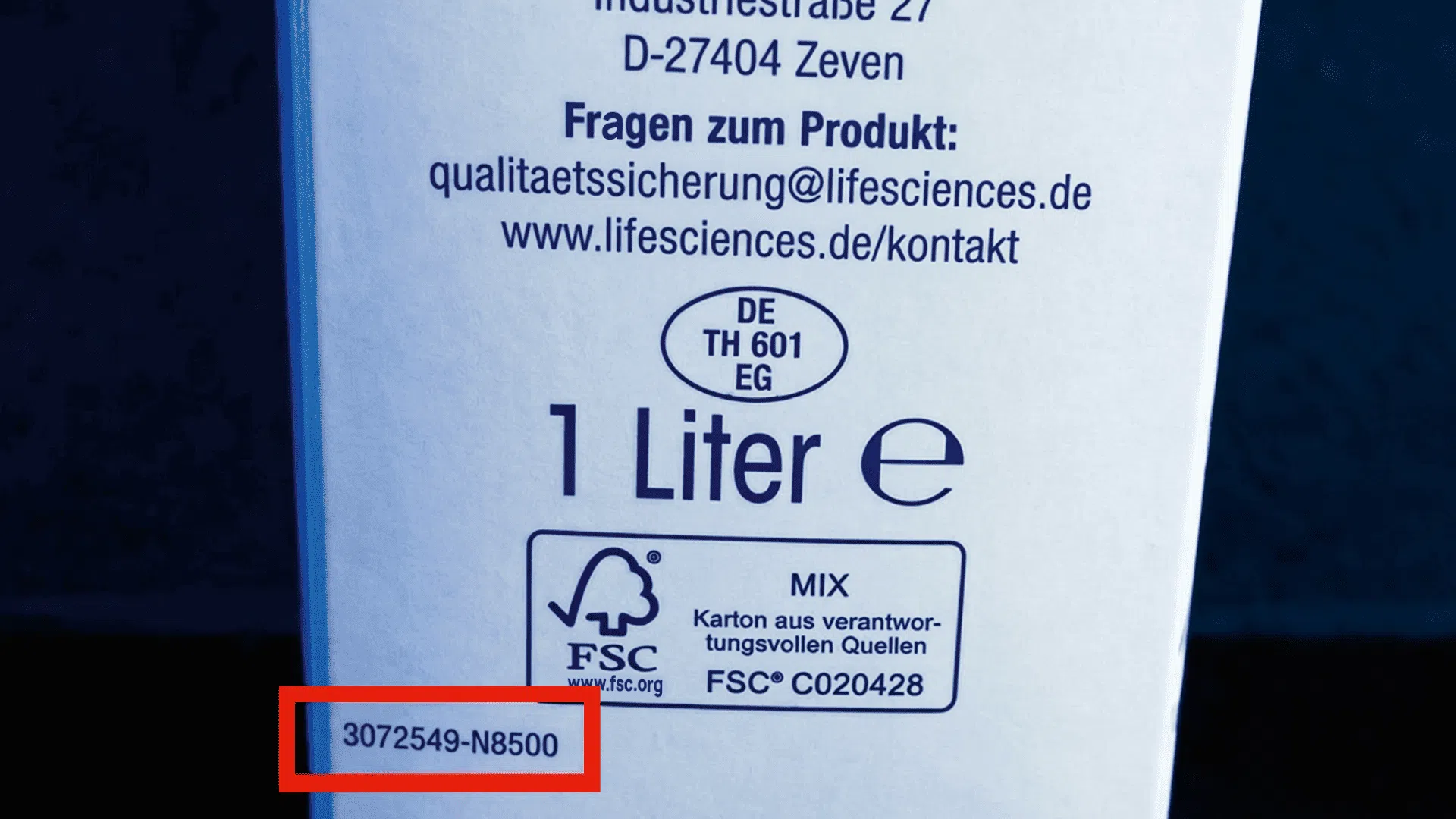

A batch refers to the total quantity of an item produced in a single production run under consistent conditions. To identify this batch, a batch number is assigned. It is also known as a lot number and is usually printed directly on the product or its packaging. In practice, the batch number is documented consistently and systematically – from production through to storage.

B12345678-AB

This sample batch number consists of:

Using batch numbers is a fundamental requirement in almost every industry to ensure quality and safety. In most sectors – such as pharmaceuticals, food, or cosmetics – batch numbers are mandatory.

A batch number provides information on:

The batch number is usually printed on the product packaging – and should never be confused with the barcode or EAN number.

Batch numbers make it possible to trace a product back to its exact production process – even after delivery. The goal is seamless lot tracking. This becomes especially valuable when defects occur, as an issue may not affect just one product but an entire batch. In such cases, faulty batches can be tracked and removed from the market as quickly as possible.

Batch numbers enable companies to trace the production path of a specific product from raw material intake to the end customer. This is particularly important in regulated industries such as pharmaceuticals, food, and cosmetics to ensure that every product meets quality standards and complies with all relevant regulations.

With batch numbers, companies can systematically perform and document quality controls. If a quality issue is detected, the affected batch can be quickly isolated and analyzed to identify and resolve the root cause.

In the event of product defects or safety issues, batch numbers allow for efficient and targeted recalls. Instead of recalling all products, only the affected batches need to be withdrawn – saving costs and minimizing reputational damage.

Batch numbers support monitoring and managing stock levels. They enable accurate inventory tracking and help prevent overstocking or shortages. They also simplify FIFO (first in, first out) and LIFO (last in, first out) processes, ensuring that older inventory is used first.

Many industries are legally required to guarantee product traceability. Batch numbers play a crucial role in meeting these requirements and standards, such as Good Manufacturing Practices (GMP) in the pharmaceutical industry or FDA regulations.

Batch numbers provide the foundation for detailed analysis and reporting across the entire production and supply chain. Companies can identify trends, optimize production processes, and make informed decisions based on collected data.

By being able to identify and trace specific batches, companies can respond directly to customer inquiries or complaints. This improves customer satisfaction and strengthens trust in the brand.

Batch numbers play a crucial role in industries such as chemicals, cosmetics, food, biotechnology, pharmaceuticals, and medical technology. Their importance spans across traceability, quality assurance, regulatory compliance, and customer satisfaction.

In addition to details such as product designation, list of ingredients and additives, or best-before date, batch numbers are mandatory for labeling food products. If a food product poses a potential risk to consumers (e.g., due to contamination), faulty batches can be identified and recalled through a product recall.

In Germany, the Medicinal Products Act (derived from EU GxP guidelines) regulates the labeling requirements for medicines. Alongside information such as the product name, strength, and dosage form, manufacturers must also include the marketing authorization number – and for batch-produced medicines, the batch designation (“CH-B”).

With the introduction of the Medical Device Regulation (MDR), a Unique Device Identification (UDI) became mandatory across the EU. This requirement ensures that medical devices can be identified and registered, enabling effective and precise traceability.

Creating batch numbers is an essential part of production and supply chain processes, as they enable product traceability and quality assurance.

Here are the key steps and considerations in creating batch numbers:

The first step is to establish a format for the batch number. This can be a combination of numbers and letters and should contain clear information about the batch. Common components include:

Each batch number must be unique to prevent confusion. A well-designed numbering system ensures that no duplicates are assigned.

Many companies use ERP systems (Enterprise Resource Planning) to automate batch number assignment. This reduces errors and ensures that numbers are consistent and compliant.

In some cases – especially in smaller companies or for specific products – batch numbers may be assigned manually. In these cases, it is important to follow a clear and consistent method to avoid mistakes.

The assigned batch number must be clearly marked on the product or its packaging. It should also be recorded in all relevant documentation, such as production logs and delivery documents.

The batch number must accompany the product at every stage of the supply chain. This makes traceability easier in the event of recalls or quality checks.

Procedures for assigning batch numbers should be reviewed regularly and improved as needed to keep up with changing requirements and technological developments.

The easiest way to track batches is with an ERP system. It allows you to record and evaluate product-specific parameters in detail. If necessary, products can be quickly traced using the batch number – and the right actions can be taken immediately.

The Yaveon 365 ERP industry solution helps batch manufacturing companies manage and track batch numbers efficiently and effectively – ensuring regulatory compliance, improving product quality, and optimizing production processes.

With Yaveon 365, you can:

Batch management explained simply – Beitrag öffnen

Batch management explained simply – Beitrag öffnen

Batch management optimizes item-specific storage and tracking of goods using a unique lot number.

Success story: Evident Ingredients – Beitrag öffnen

Success story: Evident Ingredients – Beitrag öffnen

evident ingredients simplifies batch management and secures its future with Yaveon and the Cloud.

Success story: SERO AS – Beitrag öffnen

Success story: SERO AS – Beitrag öffnen

SERO manages batches, uses tracking and recipe management, and maintains full process transparency.