We show you how the process industry can discover and unleash its greatest digital potential? Become digitally ready now!

Intelligent processes: Linking for smooth work

Efficient production: more speed with the highest quality

Freedom for innovation: less effort, more progress

More than 750 companies worldwide rely on Yaveon

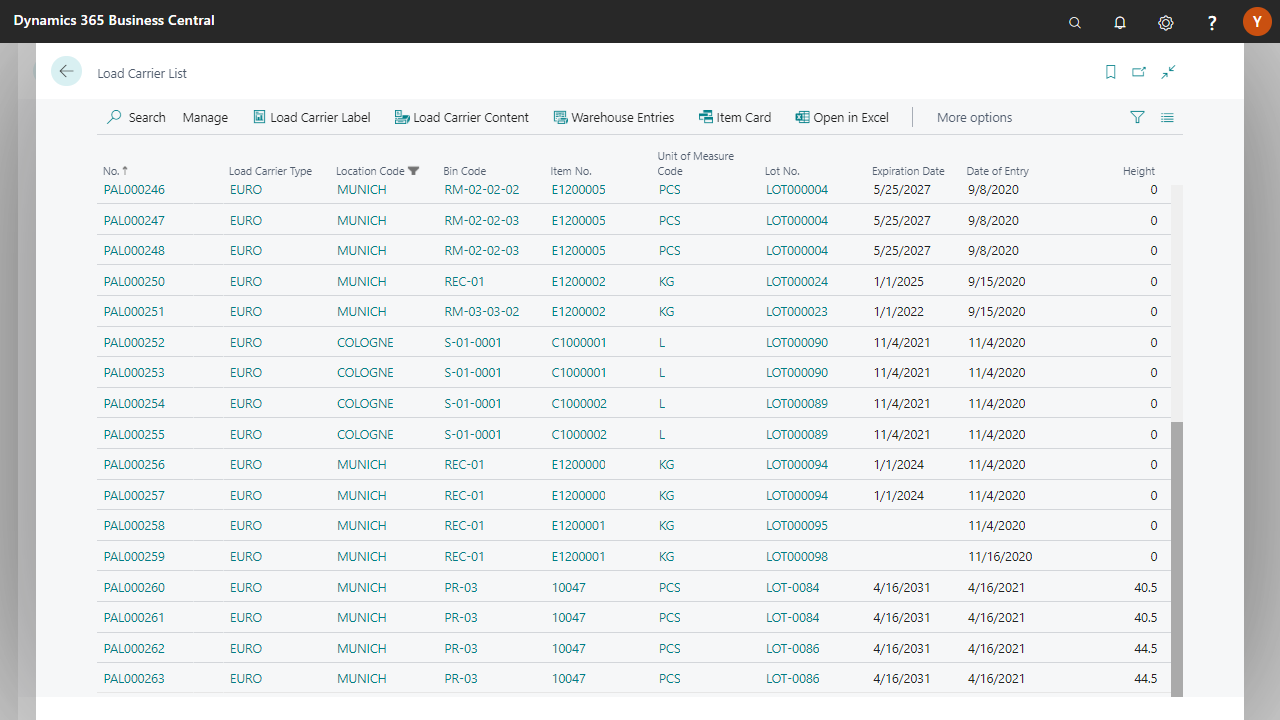

Set up item tracing

Management of batches and serial numbers

Rule management for product labels with booking rule groups

Import of stocks

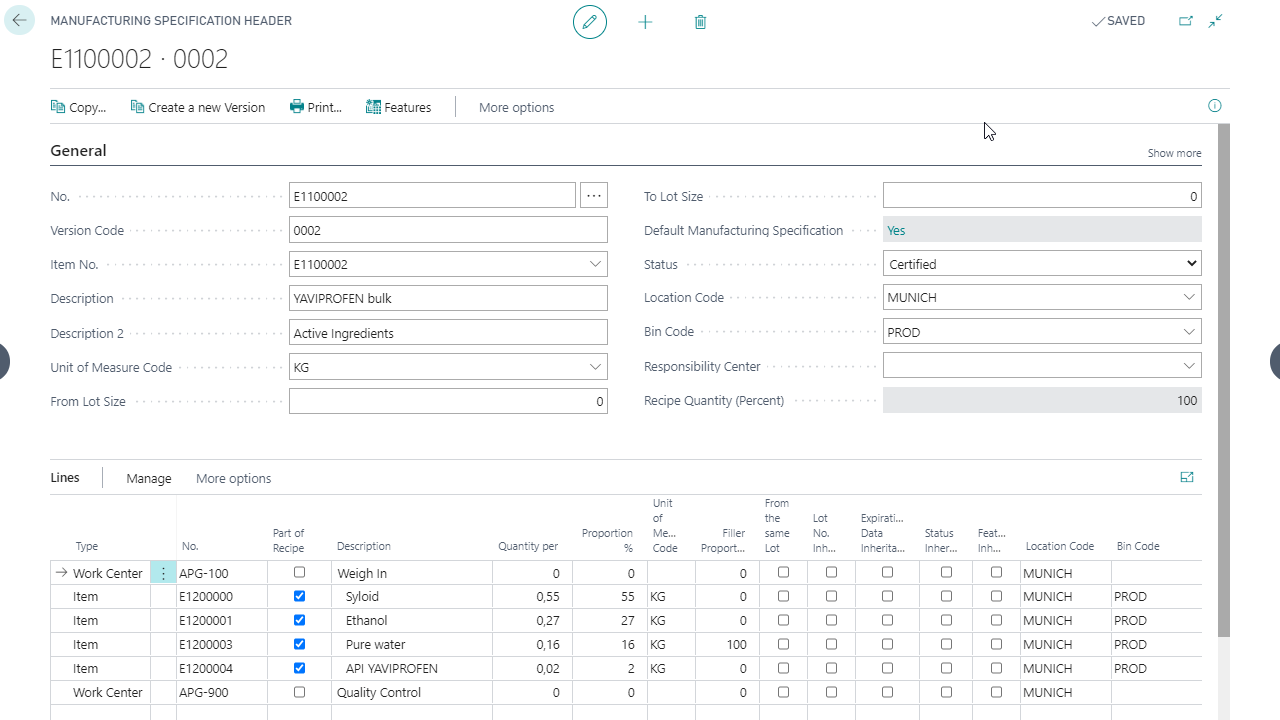

Creation of manufacturing instructions

Batch inheritance in production

Consumption posting according to FIFO/FEFO

Multi-level feature calculation

Initialization of the stock list

Automatic installation of authorization sets

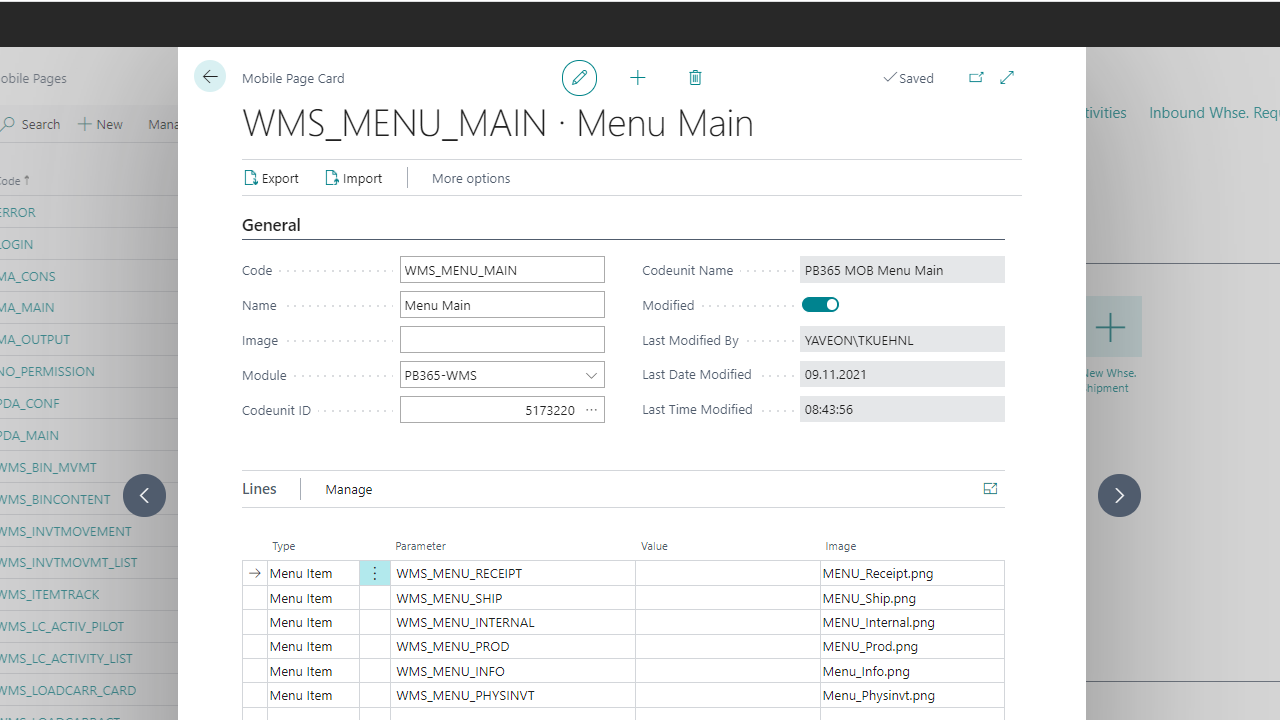

Preparation of warehouse receiving, storage and goods issue

Definition of the picking order

Setting up master data

Automatic provision of authorization records

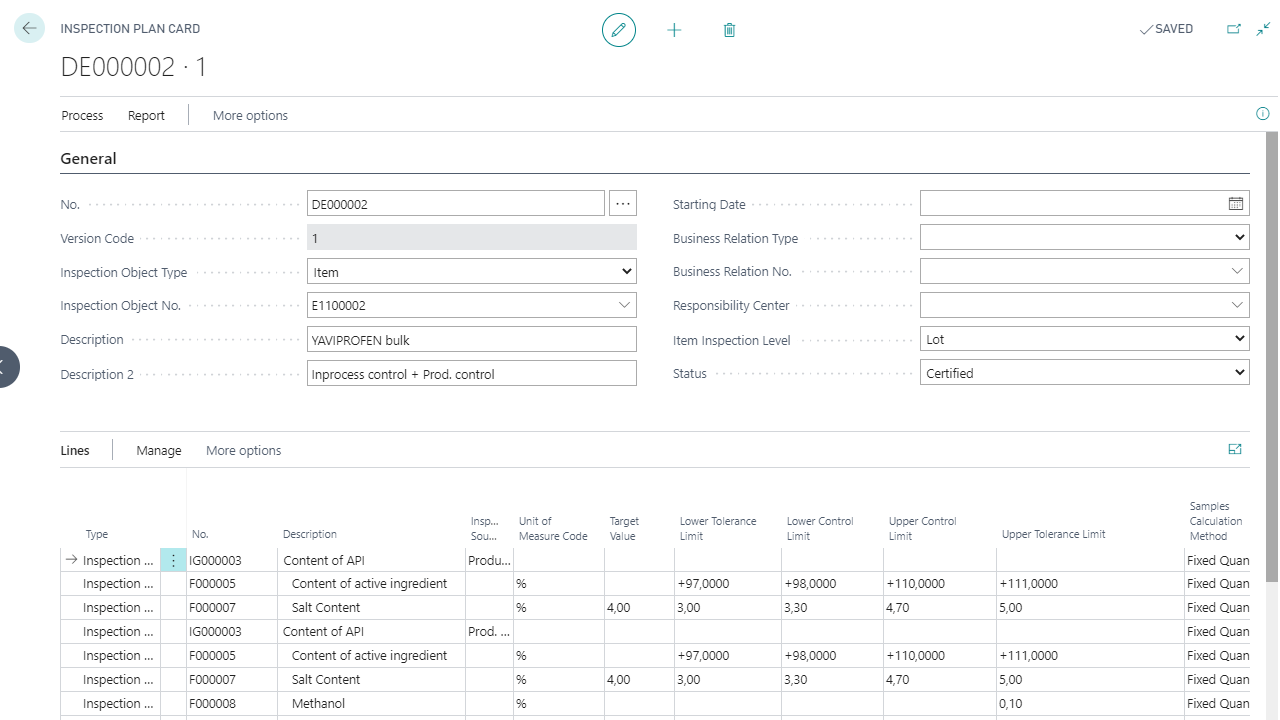

Creating test methods

Definition and implementation of inspection orders

Goods receipt dialogs

Transfer orders

Feedback of the consumption message and actual message

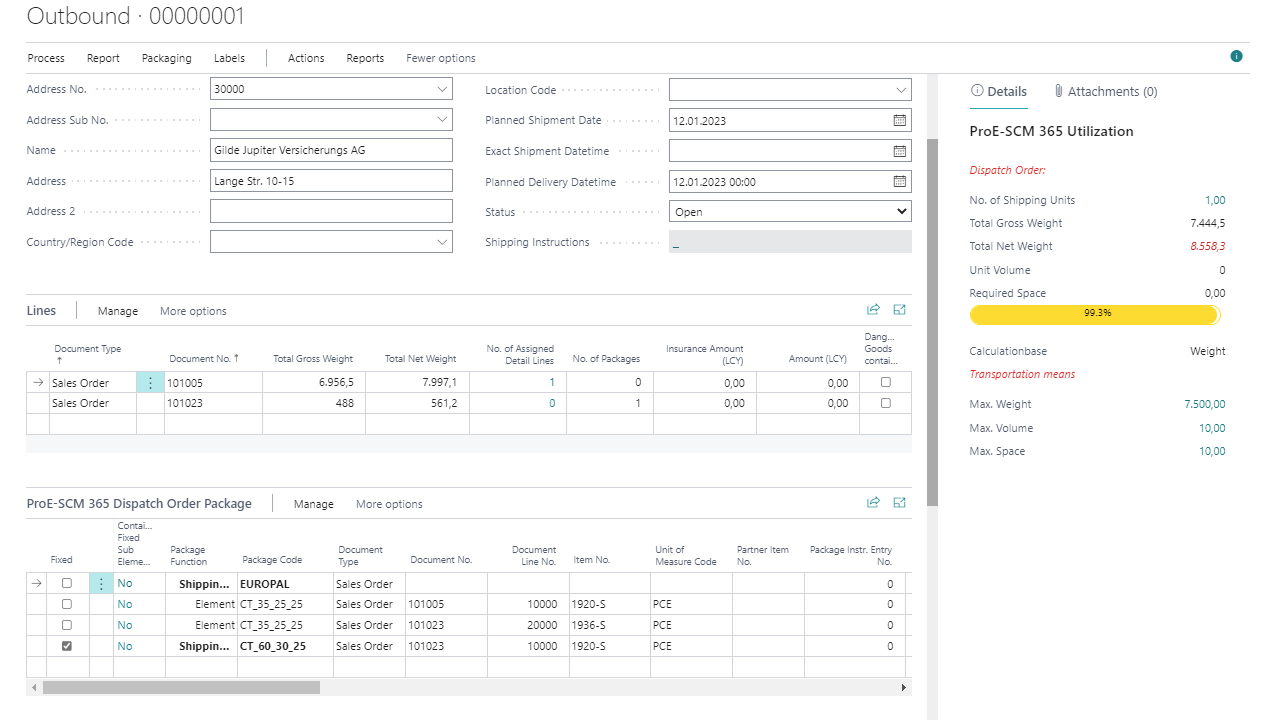

Picking dialog in outgoing goods incl. packing structure

Preallocation for new consignment orders

Definition of the types of packaging materials

Setup delivery proposals

Automatic creation of consignment orders

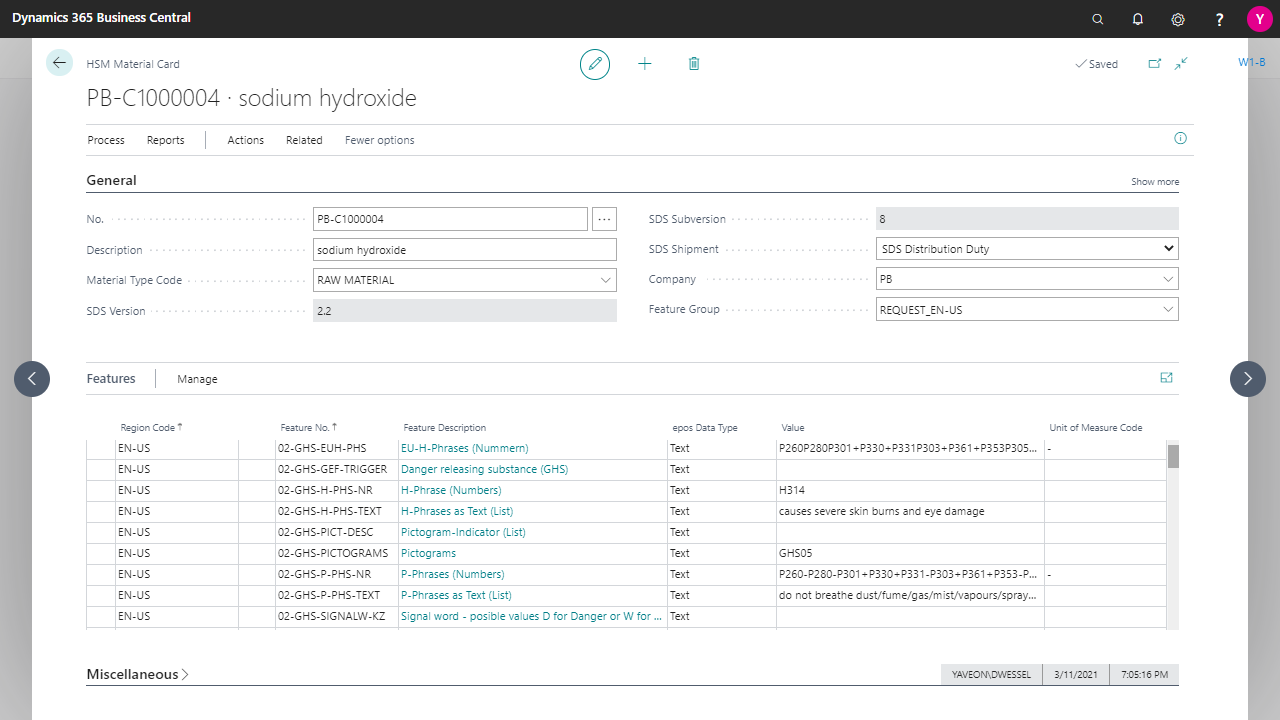

Hazardous materials management with safety data sheet

Fire department lists

Dangerous goods warehouse management

Dangerous goods management in transportation

Yaveon 365 was developed specifically for the special requirements of the chemical industry and offers a wide range of functions that make your day-to-day work easier and optimize your business processes at the same time. These include

ERP software specially tailored to the chemical industry offers far more than just process optimization. It sustainably increases efficiency and ensures that legal requirements such as REACH are reliably complied with. Such a system not only supports the management of hazardous substances and traceability, but also the precise development of formulations. The real-time data analyses are particularly helpful, enabling well-founded decisions and promoting sustainable production. In short, an ERP solution of this kind is the key to greater safety, efficiency and innovation in the chemical industry.

The introduction of an ERP system in chemical companies poses special challenges: error-free data migration, targeted training and the adaptation of business processes. With our chemical ERP solution and the proven "ProCedures" project methodology, we support you from planning to implementation - effectively, in a structured and practical manner.

The cost of implementing and maintaining an ERP system varies depending on the size of your company, the software solution selected, the level of customization and the functions required. The total costs are made up of the one-off implementation costs and the ongoing expenses for updates, support and training. Detailed cost planning helps you to determine the budget efficiently and take all necessary requirements into account.

Yes, in addition to our comprehensive online help, we offer a selection of training videos to make getting started with our chemistry software as easy and enjoyable as possible for all users. Our materials are designed to support you and your team in the long term and create confidence in using the software.

At Yaveon, innovation takes center stage. Together with Microsoft, we continuously provide you with the latest updates so that you are always at the cutting edge of technology. We accompany you on the way to future-proofing and further developing your processes.

The digital potential of the process industry – Beitrag öffnen

The digital potential of the process industry – Beitrag öffnen

We show you how the process industry can discover and unleash its greatest digital potential? Become digitally ready now!

Success story: Epple – Beitrag öffnen

Success story: Epple – Beitrag öffnen

How Epple Druckfarben AG easily covers straightforward Operations and industry-specific problems thanks to Yaveon solutions. Read now!

Success story: Schweitzer Chemie – Beitrag öffnen

Success story: Schweitzer Chemie – Beitrag öffnen

Read the report to find out how Schweitzer Chemie dissolved its self-programmed ERP system, made processes more comprehensible and much more.