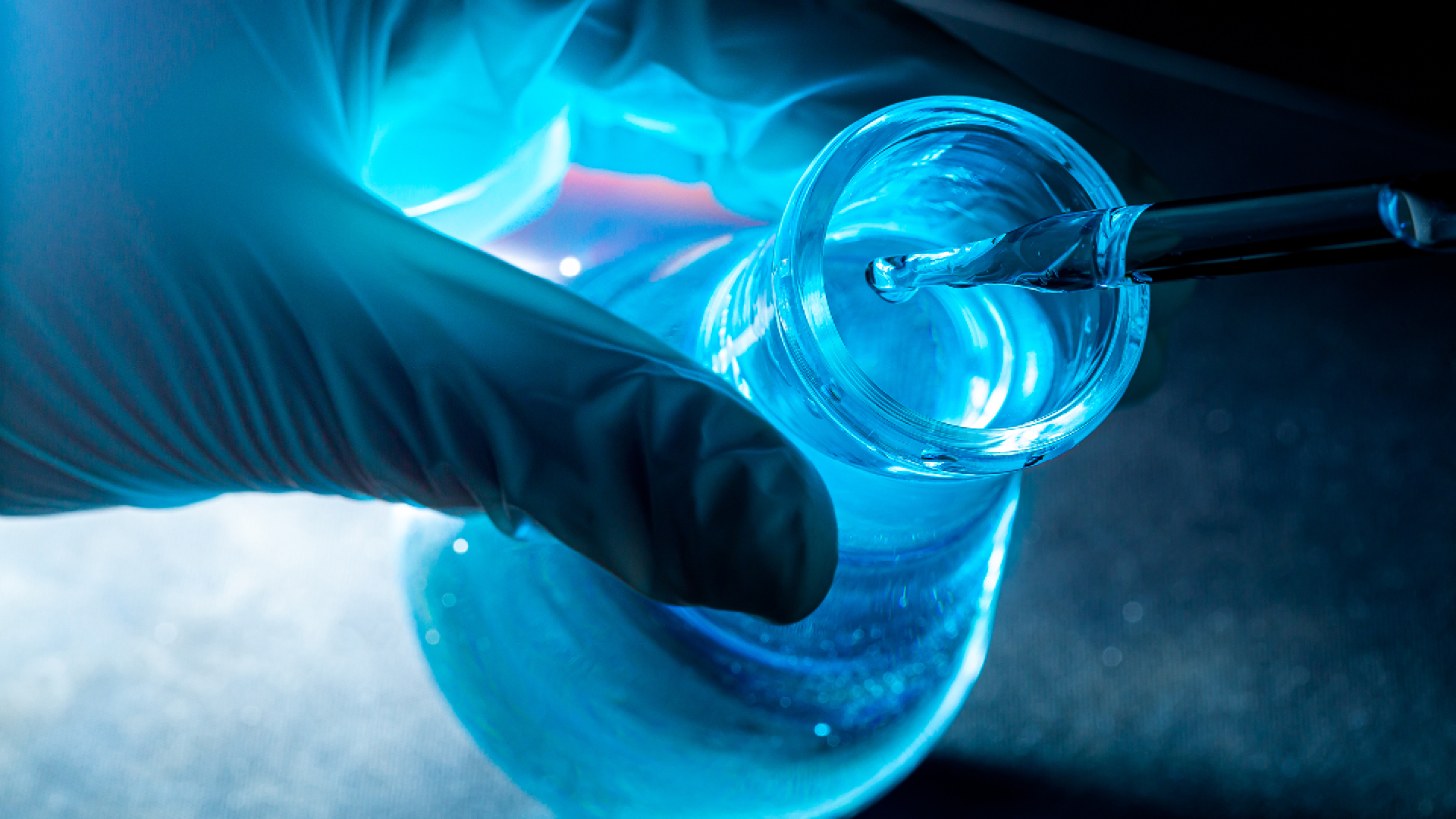

We show you how the process industry can discover and unleash its greatest digital potential.

Intelligent processes: Integration for seamless operations

Efficient production: faster speeds with the highest quality

Room for innovation: less effort, more progress

Setting up item tracing

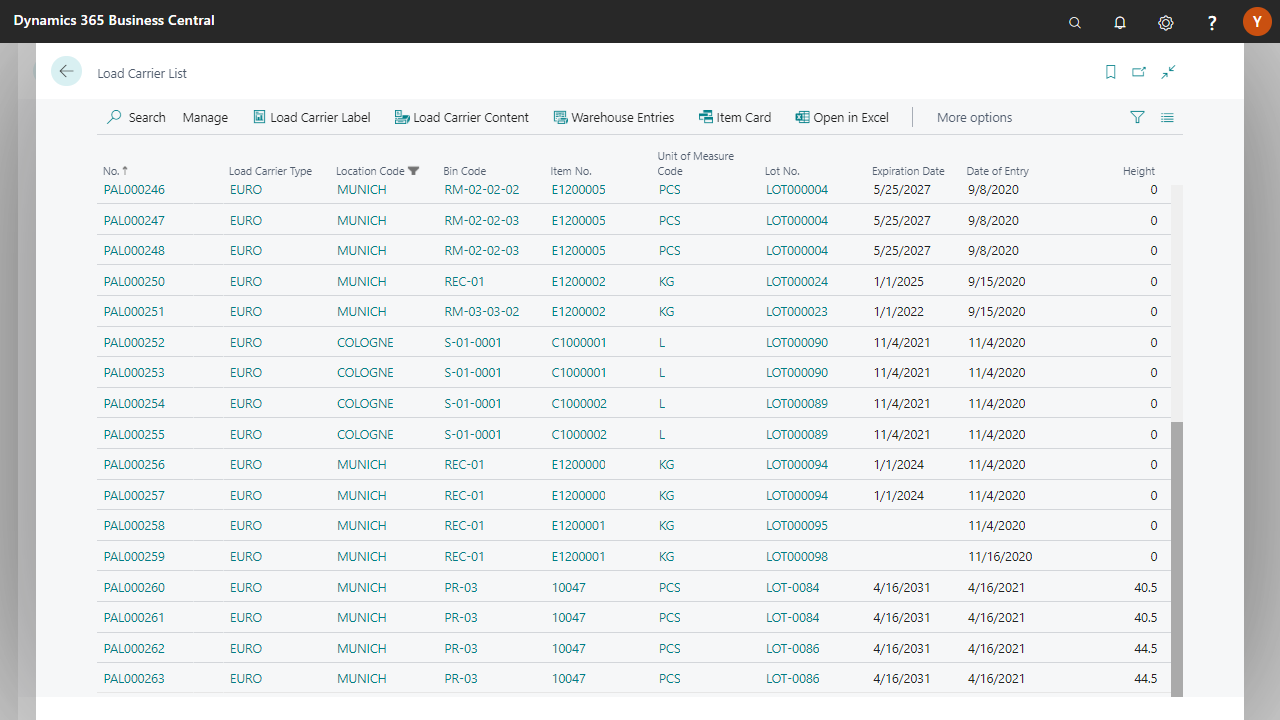

Management of batches and serial numbers

Rule management for product labels with posting rule groups

Inventory import

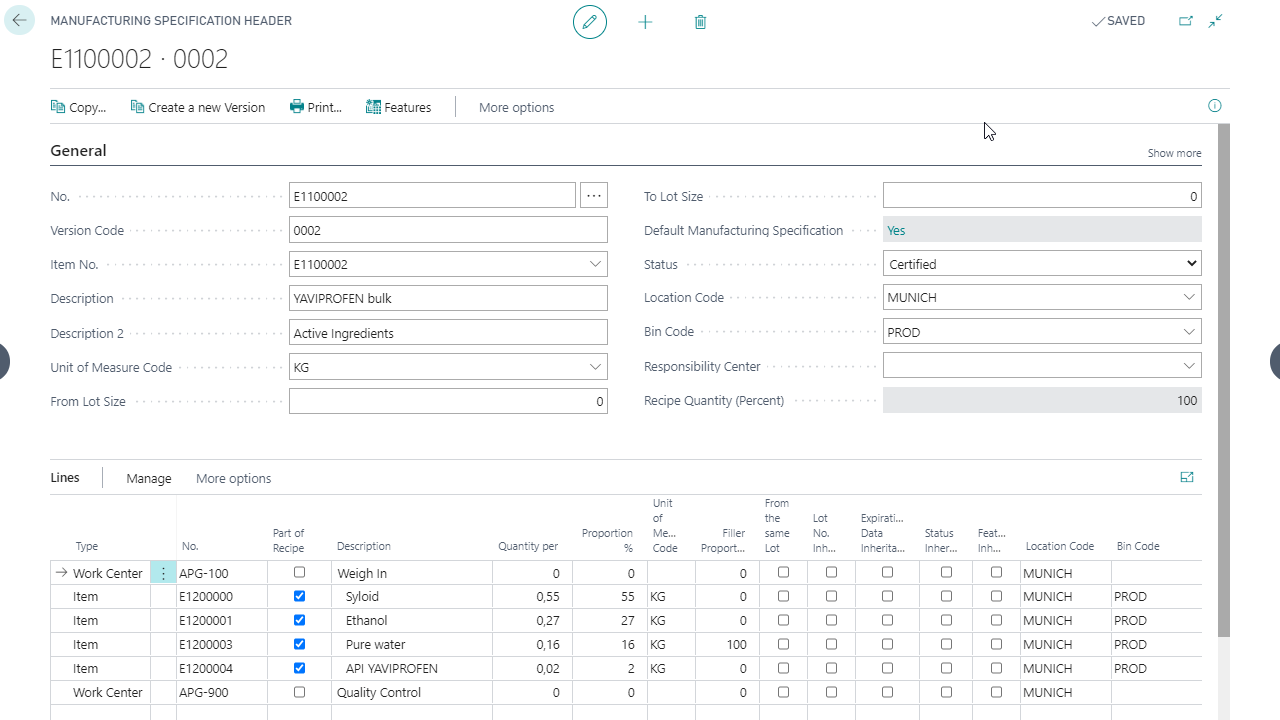

Creating manufacturing instructions

Batch inheritance in production

Consumption posting according to FIFO/FEFO

Multilevel feature calculation

Initialization of the inventory list

Automatic installation of permission sets

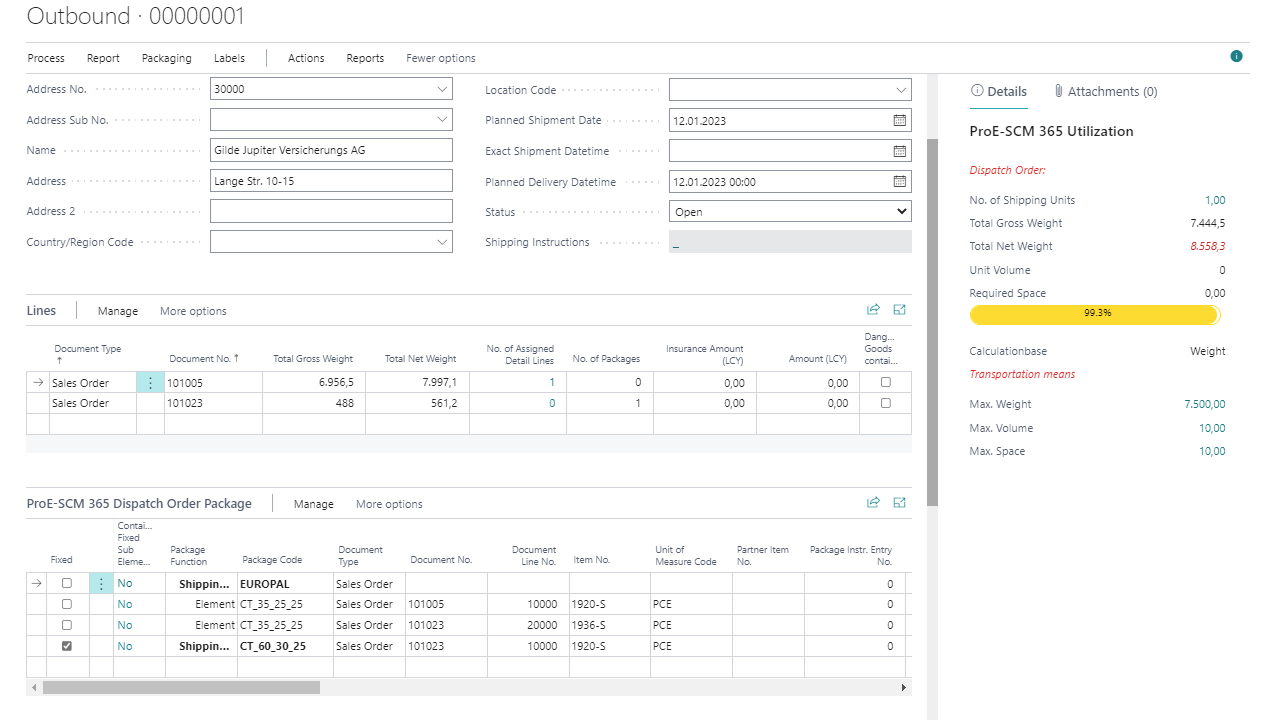

Creation of warehouse receiving, storage, and shipment

Definition of the pick order

Setting up master data

Automatic provisioning of permission sets

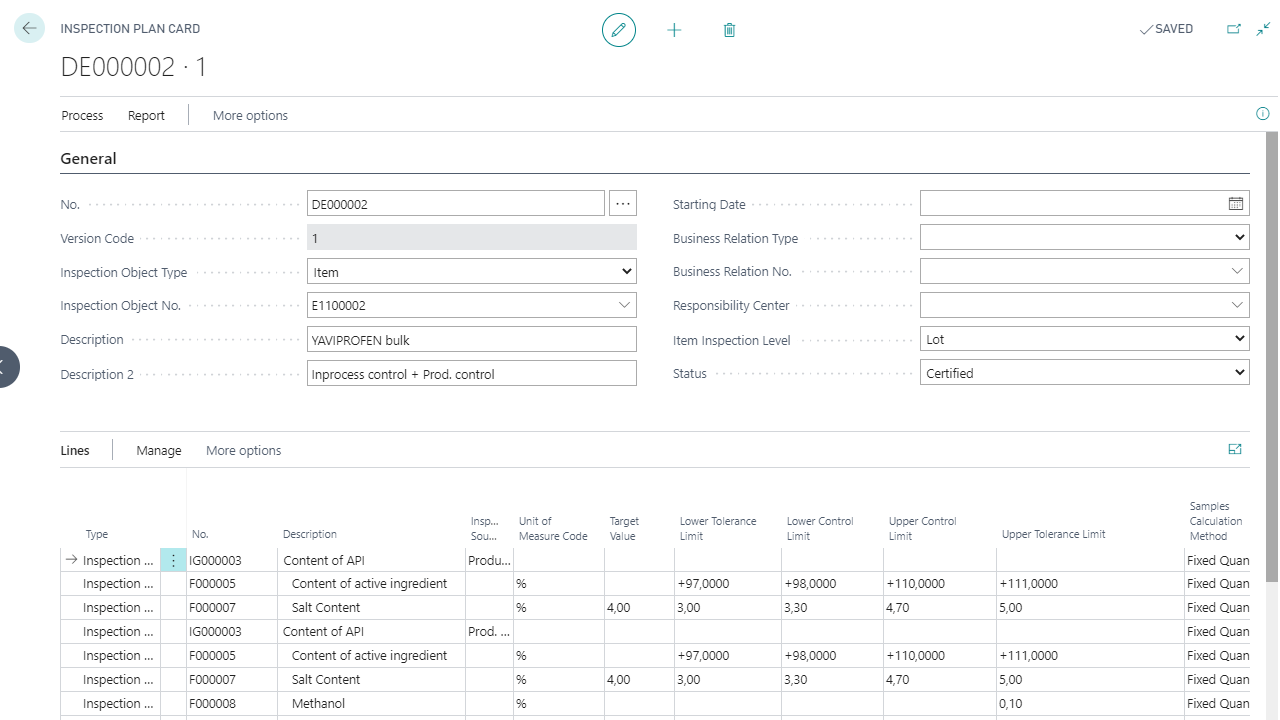

Creating inspection methods

Definition and execution of inspection orders

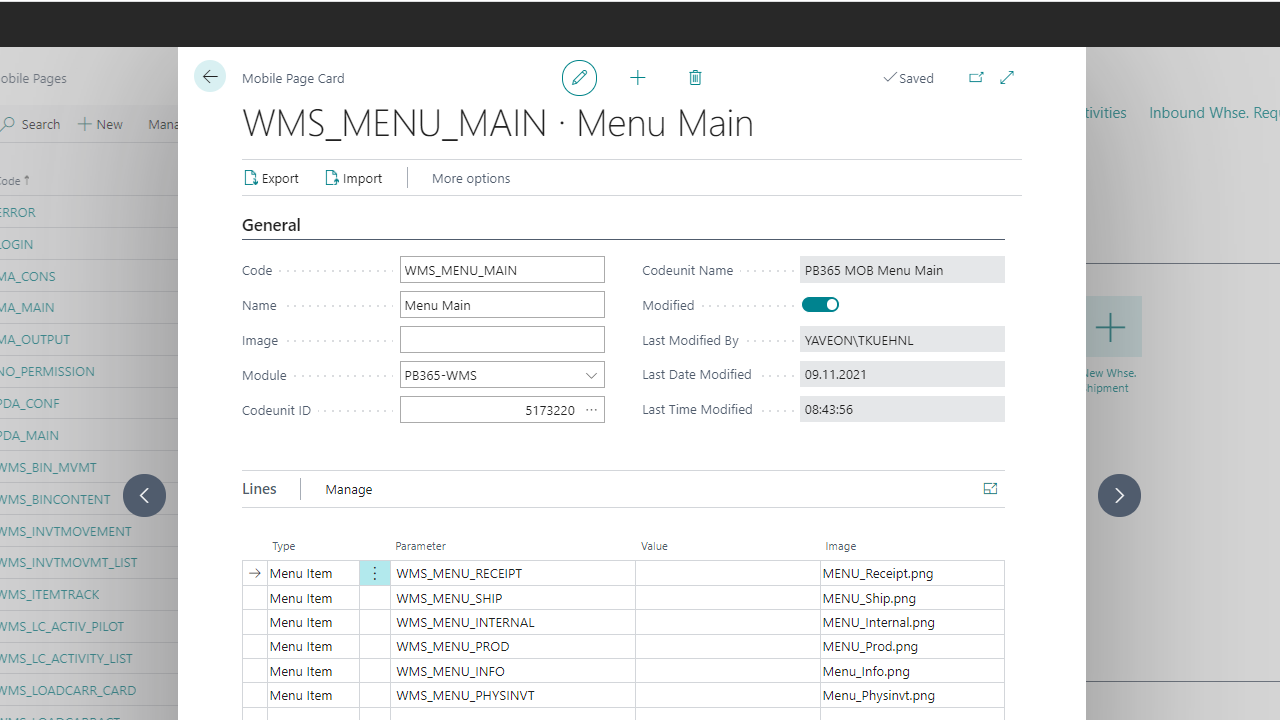

Warehouse receiving dialogs

Transfer orders

Report consumption notification and actual notification

Order picking dialog in warehouse receiving, including packing structure

Default settings for new shipping orders

Definition of types of packaging materials

Setup delivery proposals

Automatic creation of shipment orders

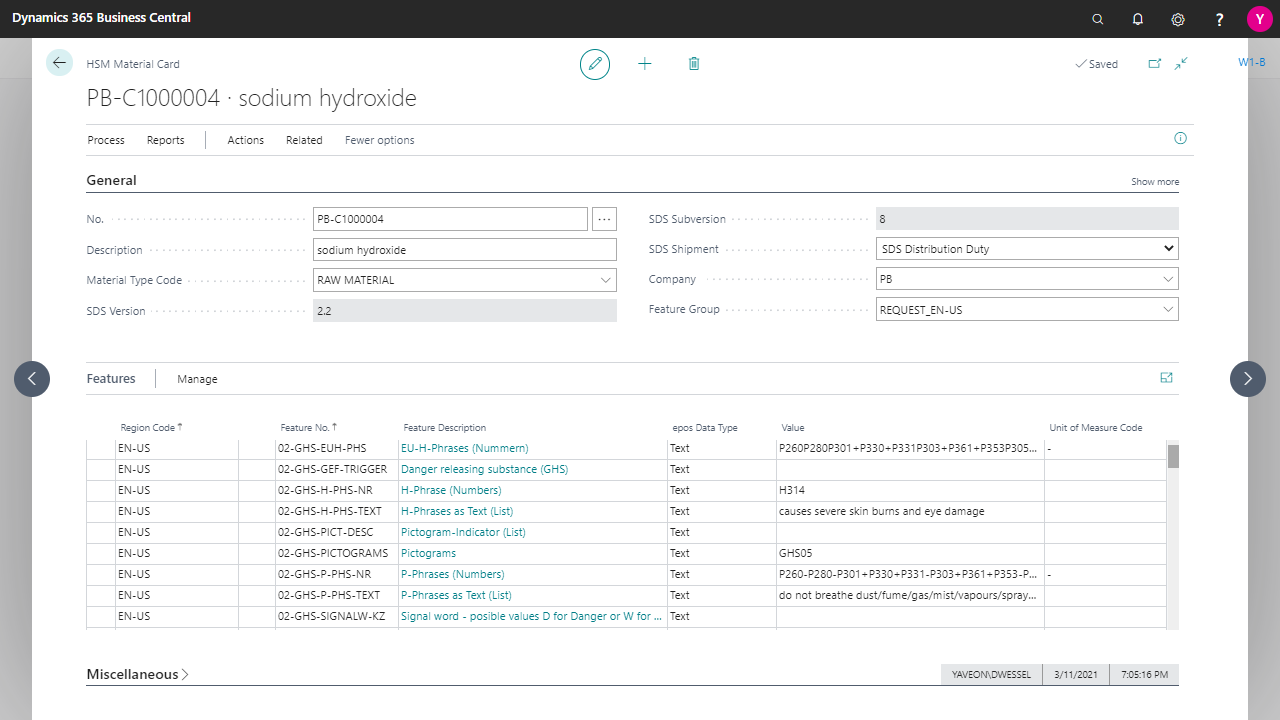

Hazardous materials management with safety data sheet

Fire brigade lists

Hazardous goods warehouse management

Hazardous materials management in transport

Yaveon 365 is specifically designed for the unique needs of the chemical industry and offers a wide range of features to streamline your daily operations and optimize your business processes. These features include:

An ERP software specifically designed for the chemical industry offers much more than just process optimization. It sustainably increases efficiency and ensures reliable compliance with legal requirements like REACH. Such a system not only aids in the management of hazardous substances and traceability but also in the precise development of recipes. Particularly helpful are the real-time data analyses that enable informed decision-making and promote sustainable production. In short, this kind of ERP solution is the key to enhanced safety, efficiency, and innovation in the chemical industry.

Implementing an ERP system in chemical companies involves unique challenges: flawless data migration, targeted training, and business process adaptation. Our chemical industry ERP solution and the proven project methodology “ProCedures” support you from planning to implementation—effectively, systematically, and practically.

The costs associated with implementing and maintaining an ERP system vary based on your company's size, the chosen software solution, the degree of customization, and required functionalities. Total costs comprise one-time implementation charges and ongoing expenses for updates, support, and training. Detailed cost planning assists in efficiently setting a budget while considering all necessary requirements.

Yes. In addition to our extensive online help, we offer a selection of training videos to make getting started with our chemical industry software as easy and enjoyable as possible for all users. Our materials are designed to provide long-term support for you and your team, ensuring confidence in using the software.

Innovation is at the core of Yaveon. Together with Microsoft, we consistently provide you with the latest updates, ensuring you stay at the forefront of technology. We support you in future-proofing and advancing your processes.

The digital potential of the process industry – Beitrag öffnen

The digital potential of the process industry – Beitrag öffnen

We show you how the process industry can discover and unleash its greatest digital potential.

Success story: Epple – Beitrag öffnen

Success story: Epple – Beitrag öffnen

Epple Druckfarben AG streamlines operations and solves industry-specific challenges with Yaveon solutions – read the report now!

Success story: Schweitzer Chemie – Beitrag öffnen

Success story: Schweitzer Chemie – Beitrag öffnen

Read the report to find out how Schweitzer Chemie dissolved its self-programmed ERP system, made processes more comprehensible and much more.