How seamless lot tracking empowers biotech companies with maximum transparency and regulatory compliance.

Efficient Development: Safely turning ideas into products

Top Quality: Maintain standards through quality control

Complete Security: Ensure Traceability and Compliance

More than 850 companies worldwide rely on Yaveon

Set up item tracing

Manage batches and serial numbers

Rule management for product labels with posting rule groups

Import inventory levels

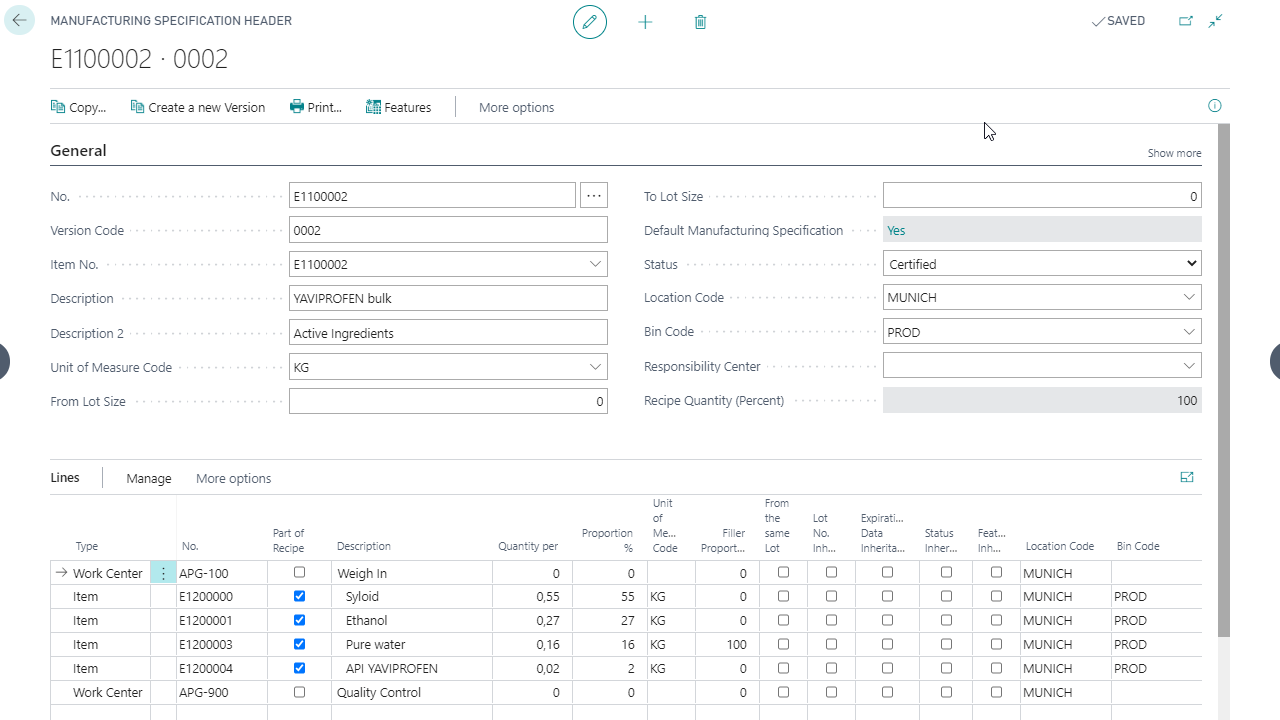

Create manufacturing guidelines

Batch inheritance in production

Post consumption using FIFO/FEFO

Multilevel feature calculation

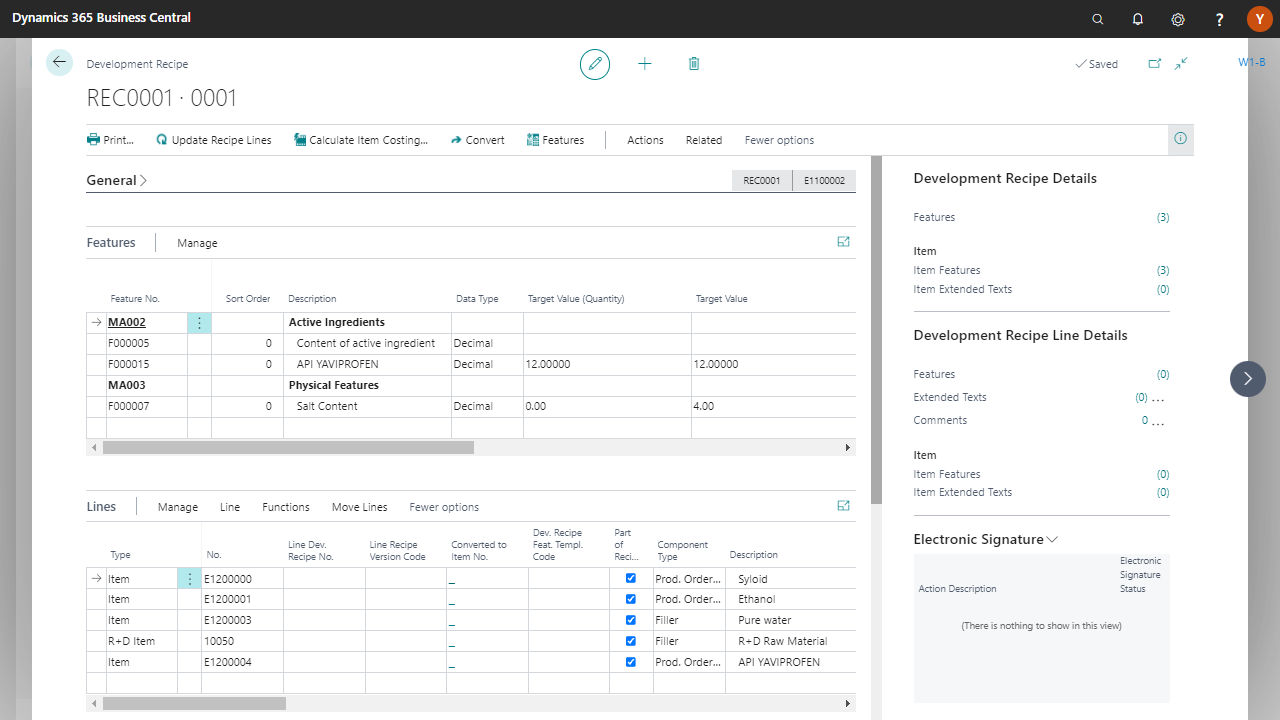

Manage R&D items

Create development recipes

Document versions

Compare recipes

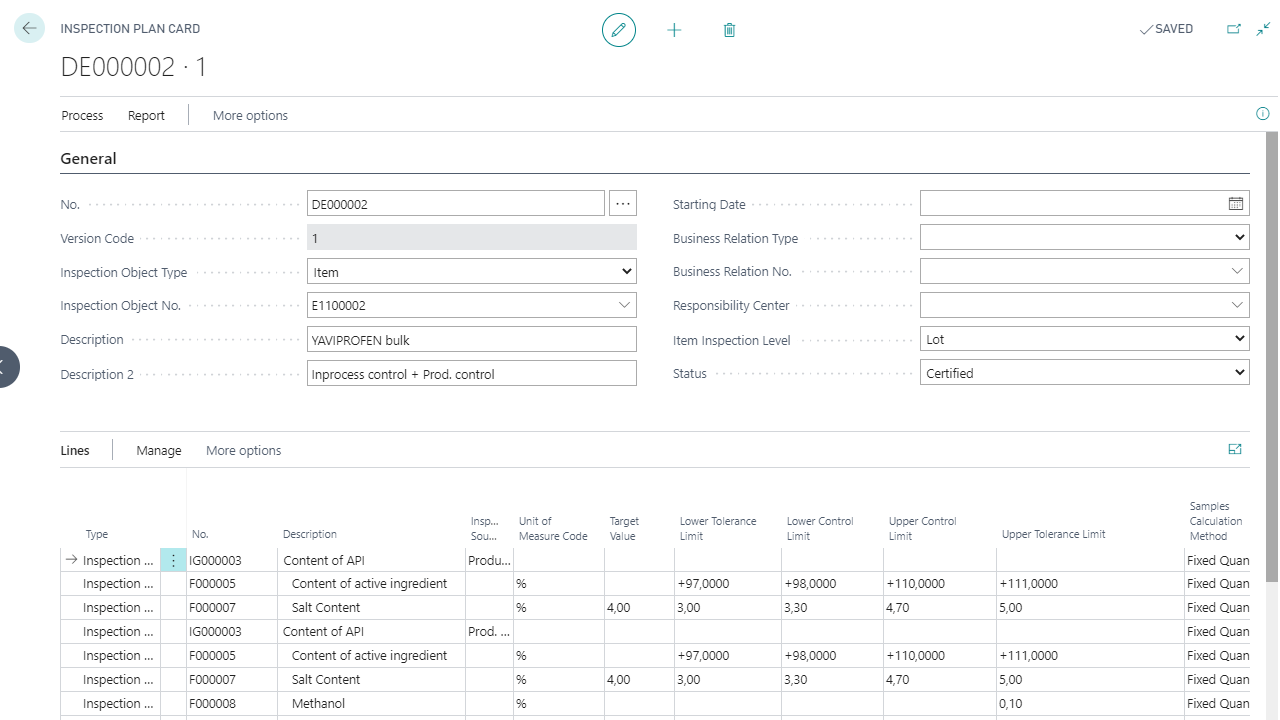

Create inspection methods

Define and execute inspection orders

Set up master data

Assign authorization sets

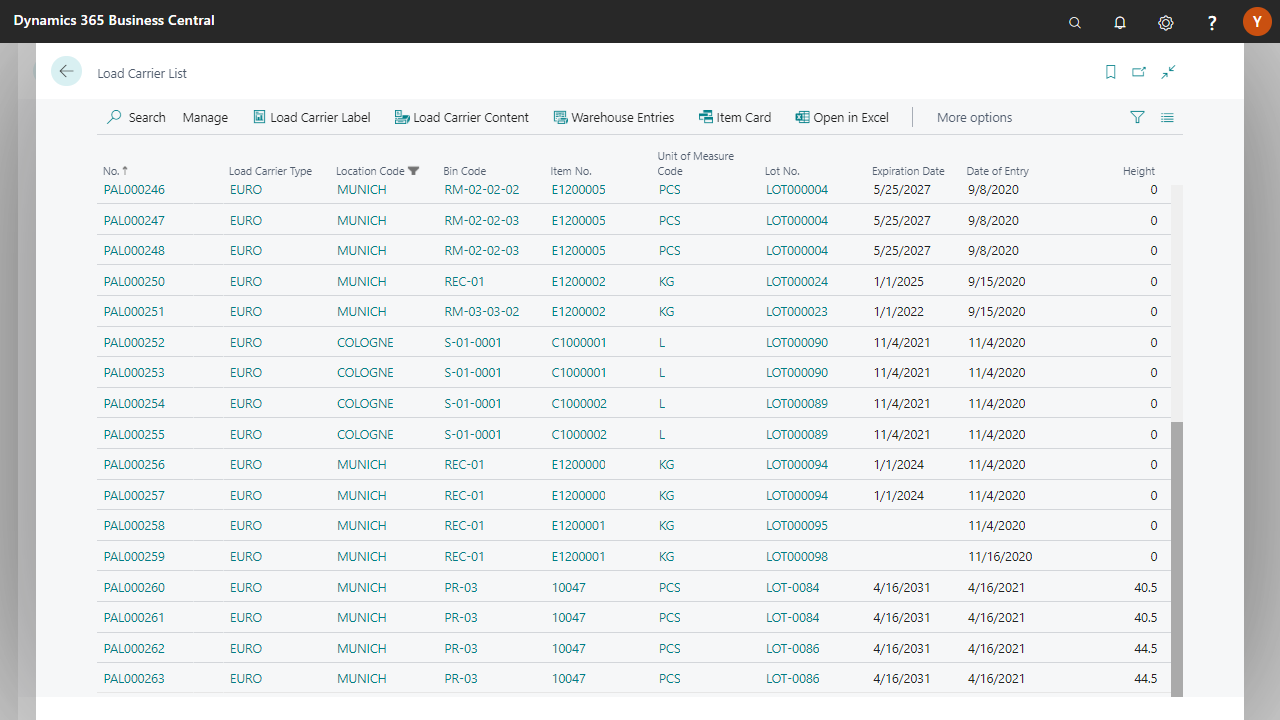

Initializing the inventory list

Automatic installation of permission sets

Creation of warehouse receiving, storage, and shipment

Definition of the pick order

Assignment of Permission Sets

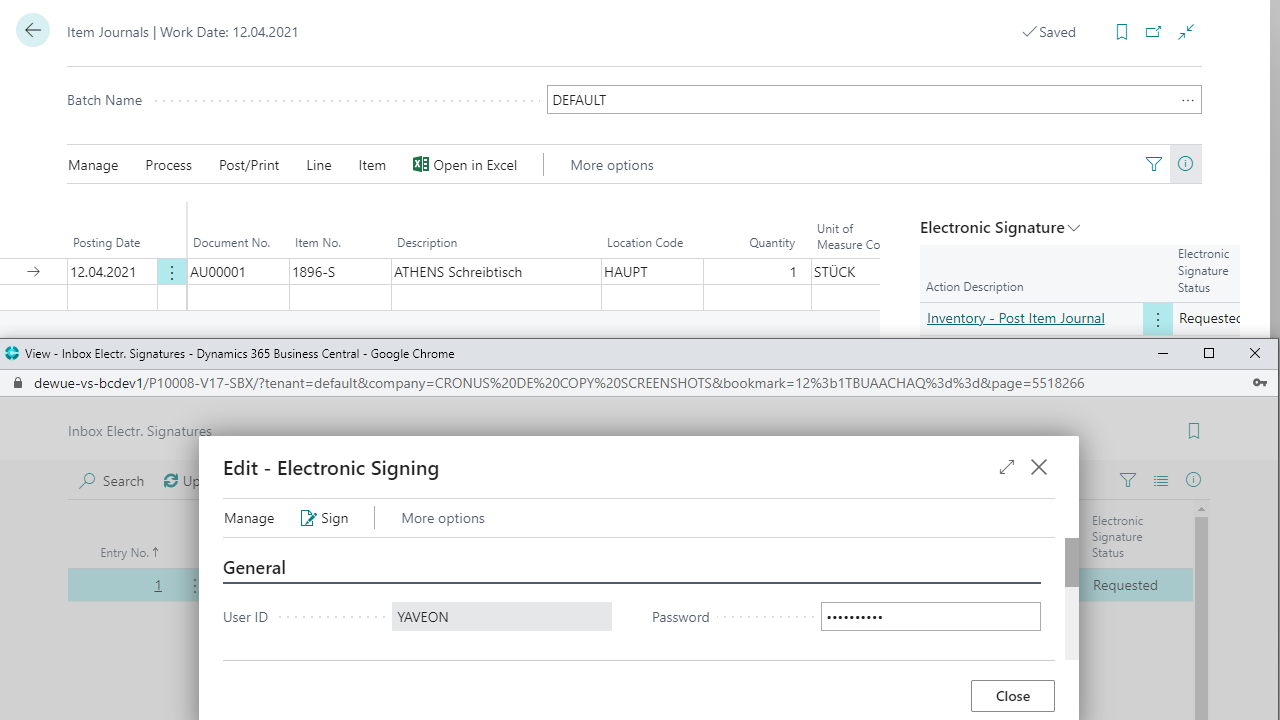

Electronic Signature

Tracking Database Changes with Audit Trail

Field Security for User-Dependent Rights

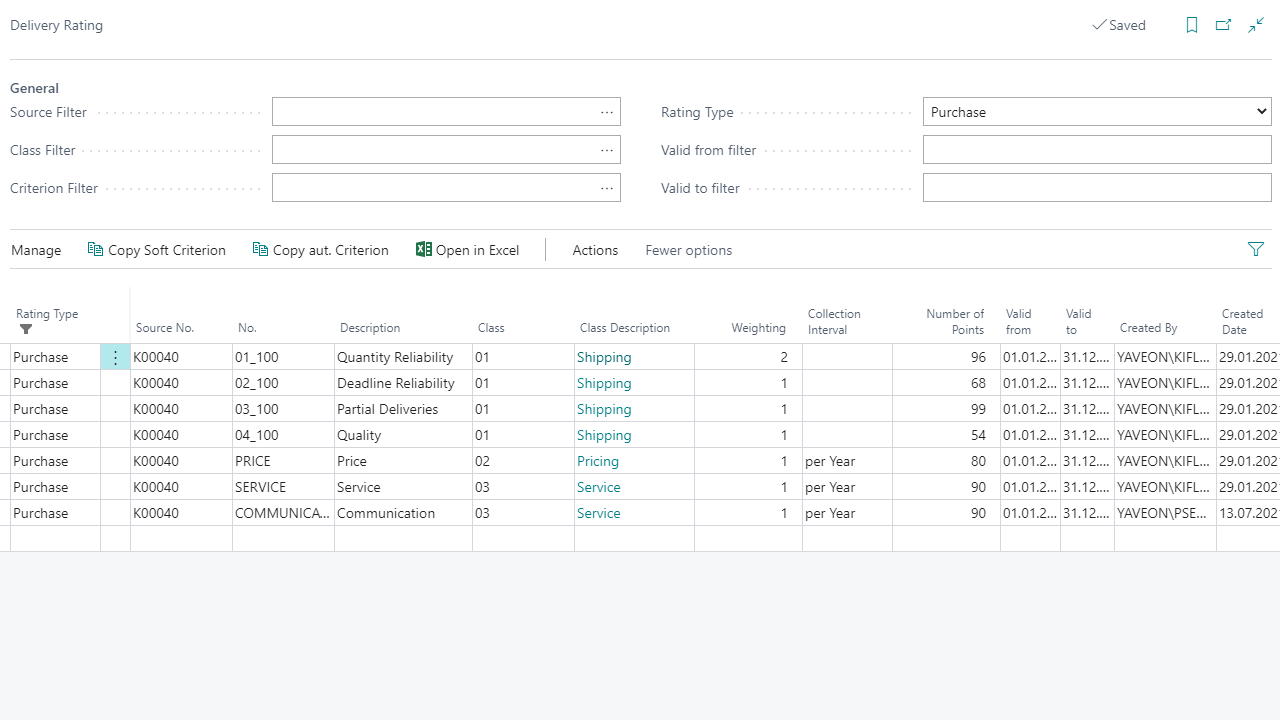

Internal & External Supplier Evaluation

Assignment of Evaluation Criteria

Deadline Reliability, Quantity Reliability & Partial Shipments

Report Generation Based on Automatic Criteria

An ERP system provides biotech companies the opportunity to enhance process efficiency and meet regulatory requirements reliably—essential for quality audits. It optimizes resource planning in research and development, boosts productivity, and improves product quality through real-time data. Automation reduces costs, minimizes errors, and fosters innovation, ensuring companies remain competitive over the long term.

Implementing an ERP system for biotech companies presents challenges such as data migration, regulatory requirements, staff training, and adapting business processes. Our expert team supports you using Microsoft Business Central along with our industry-specific ERP solution. With our proven project methodology, ProCedures, we ensure a focused implementation. We make sure your data is transferred completely and accurately, guiding you step-by-step to a successful go-live.

The costs for implementing and maintaining an ERP system vary depending on the size of your company, the selected software solution, the level of customization, and the required features. The total costs consist of one-time implementation fees as well as ongoing expenses for updates, support, and training. A detailed cost plan helps you efficiently set the budget and consider all necessary requirements.

Yes, we make starting with our biotech ERP software as easy as possible for everyone. To support this, we offer comprehensive online help as well as a wide range of training videos, enabling fast and efficient learning. Our goal is to optimally support both beginners and experienced users.

Yaveon, like Microsoft, continually provides new updates to ensure you always have access to the latest technology solutions. Additionally, we constantly expand our product portfolio to offer you a comprehensive, future-oriented solution that meets the dynamic demands of the biotech industry.

Lot tracking in the biotech industry – Beitrag öffnen

Lot tracking in the biotech industry – Beitrag öffnen

How seamless lot tracking empowers biotech companies with maximum transparency and regulatory compliance.

Research & Development in biotechnology – Beitrag öffnen

Research & Development in biotechnology – Beitrag öffnen

How optimized processes increase efficiency and strengthen compliance in biotech research and development.

ERP Compliance in the biotech industry – Beitrag öffnen

ERP Compliance in the biotech industry – Beitrag öffnen

Learn how a validated ERP system helps biotech companies meet GMP, ISO 13485, and FDA requirements.