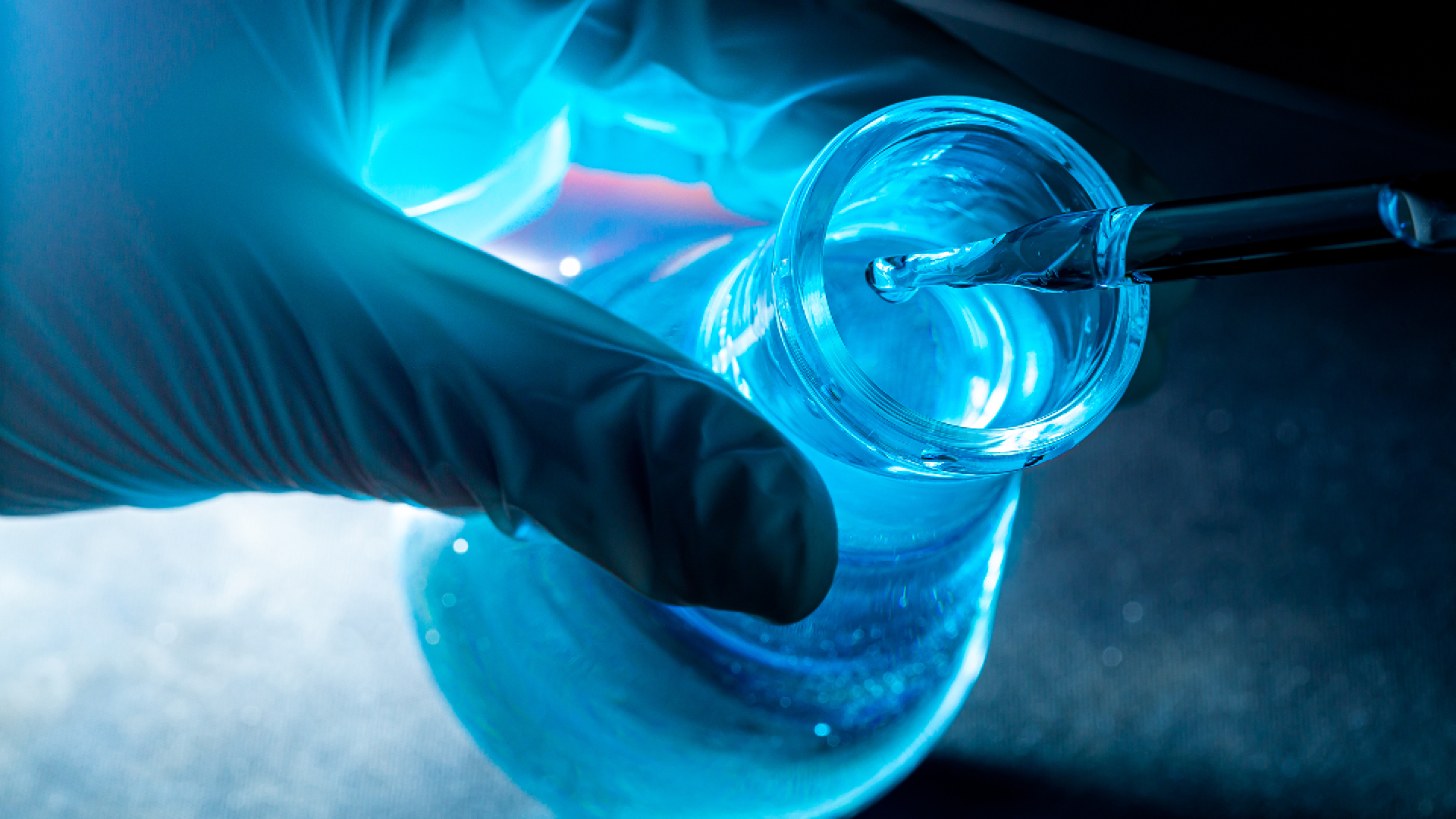

Meeting hazardous materials regulations and securing your processes – made easier with ERP

Reliable compliance: REACH, CLP & GHS included as standard

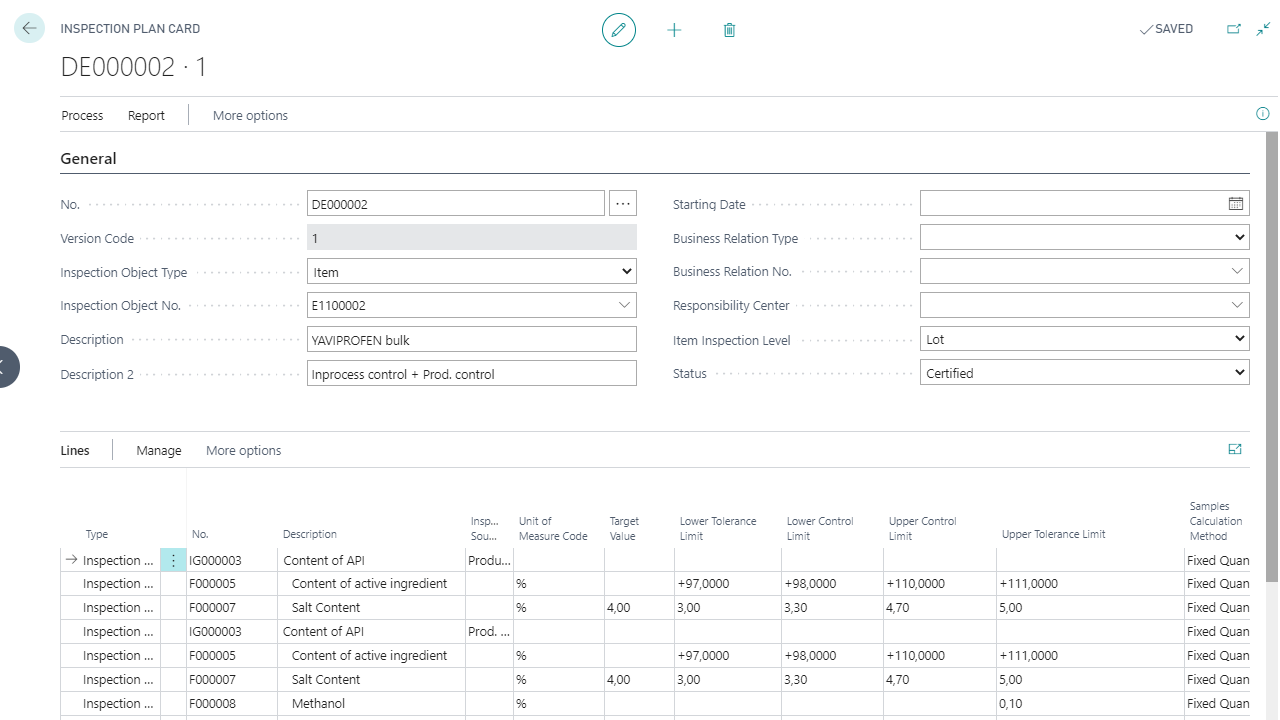

Transparent batches: Traceability & inspection plans integrated

Efficient planning: Control costs, inventories & processes

Set up item tracking

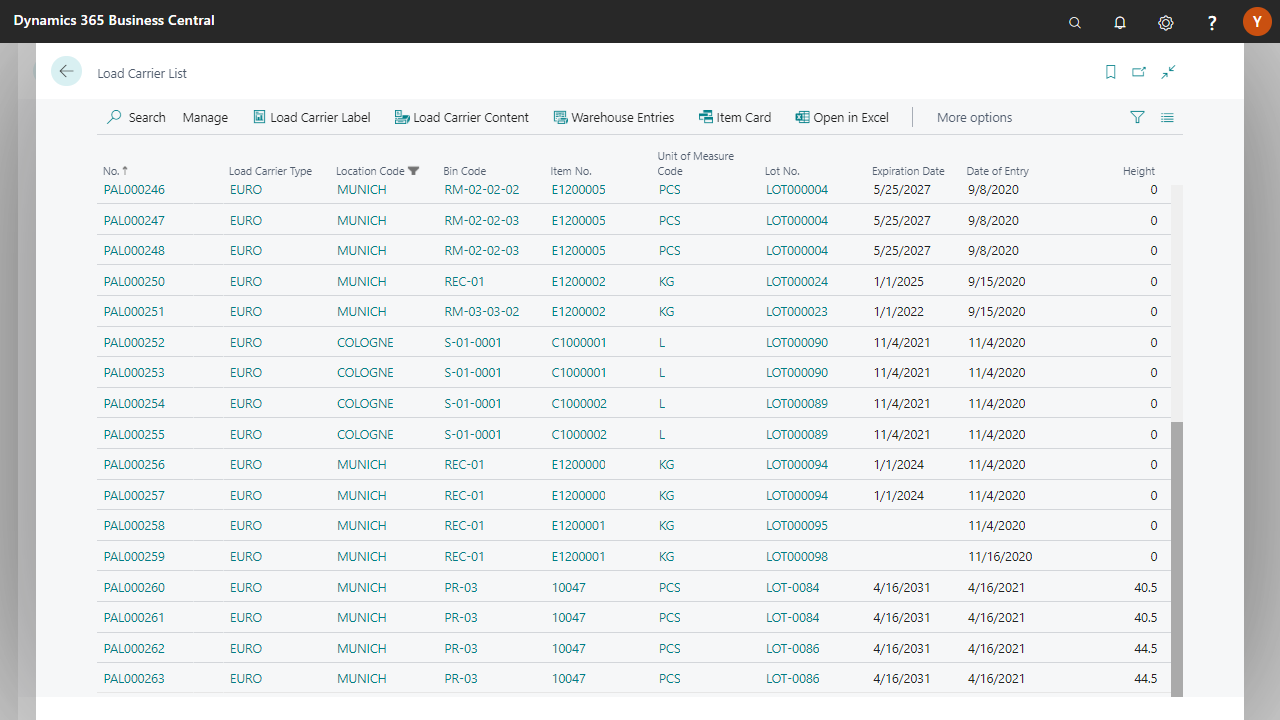

Manage batches & serial numbers

Control product labeling based on rules

Reliably import inventory

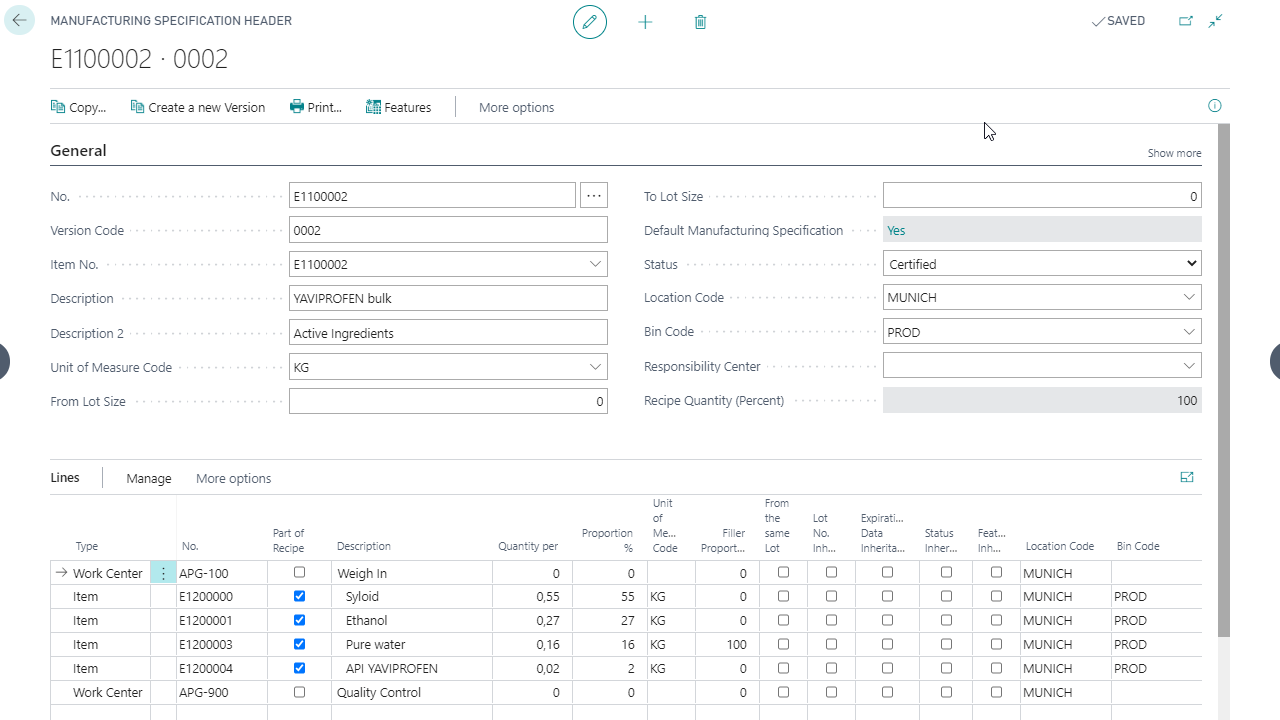

Create manufacturing instructions

Use batch inheritance in production

Post consumption using FIFO/FEFO

Perform multi-level feature calculations

Initialize inventory lists

Automatically install permission sets

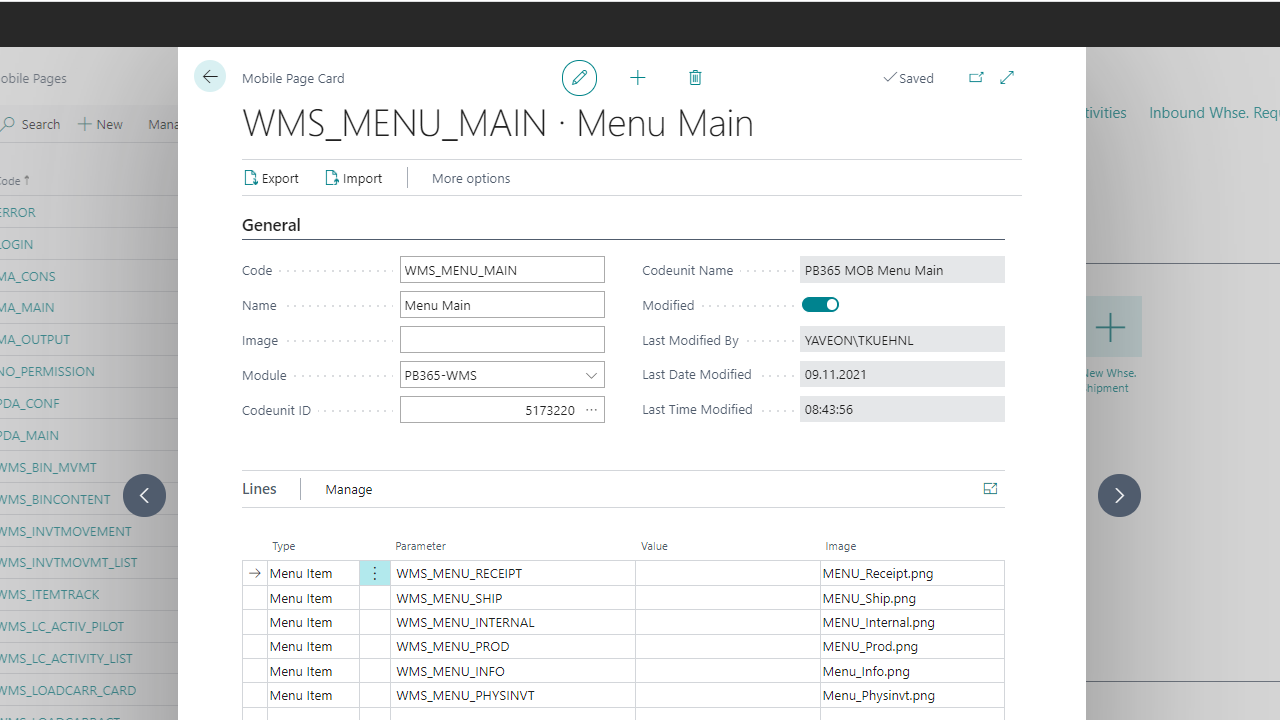

Create goods receipt, storage & shipment processes

Define picking order

Set up master data

Automatically provide permission sets

Define inspection methods

Create & execute inspection orders

Use warehouse receiving dialogs

Process transfer orders

Post consumption and actual reports

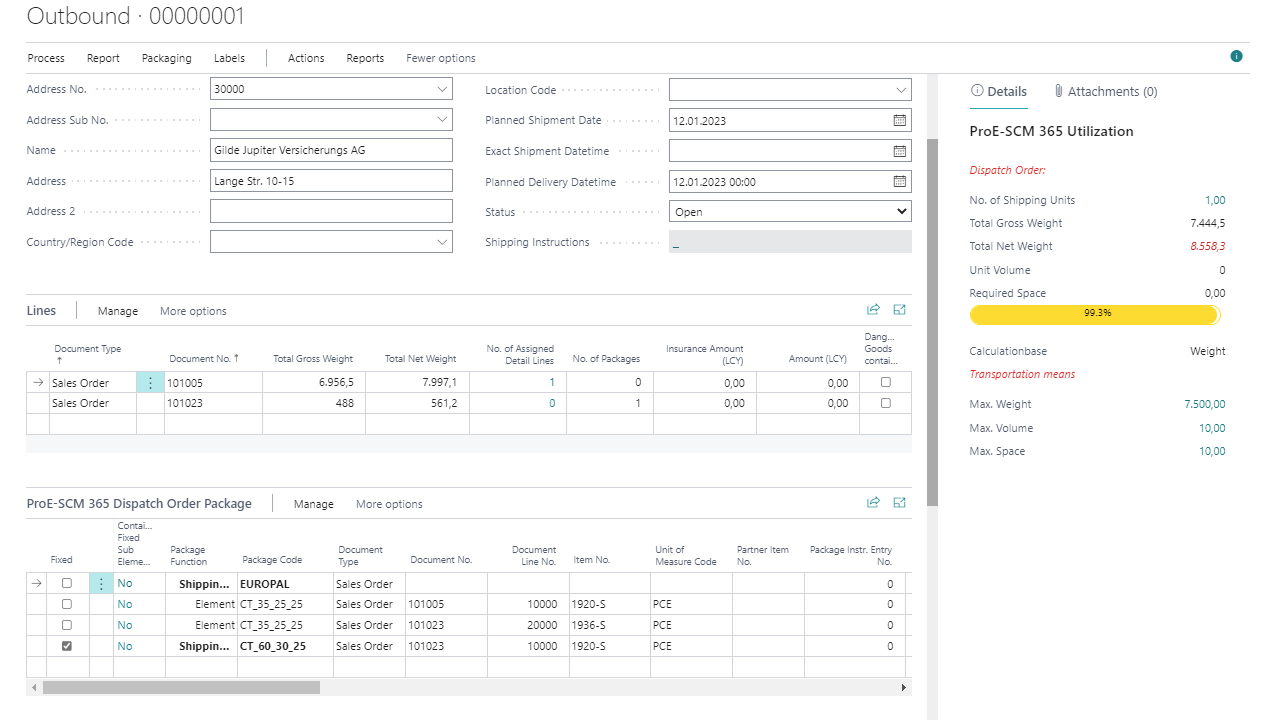

Execute picking dialogs in outbound processes including packing structure

Predefine new shipping orders

Define packaging types

Set up delivery proposals

Automatically create shipping orders

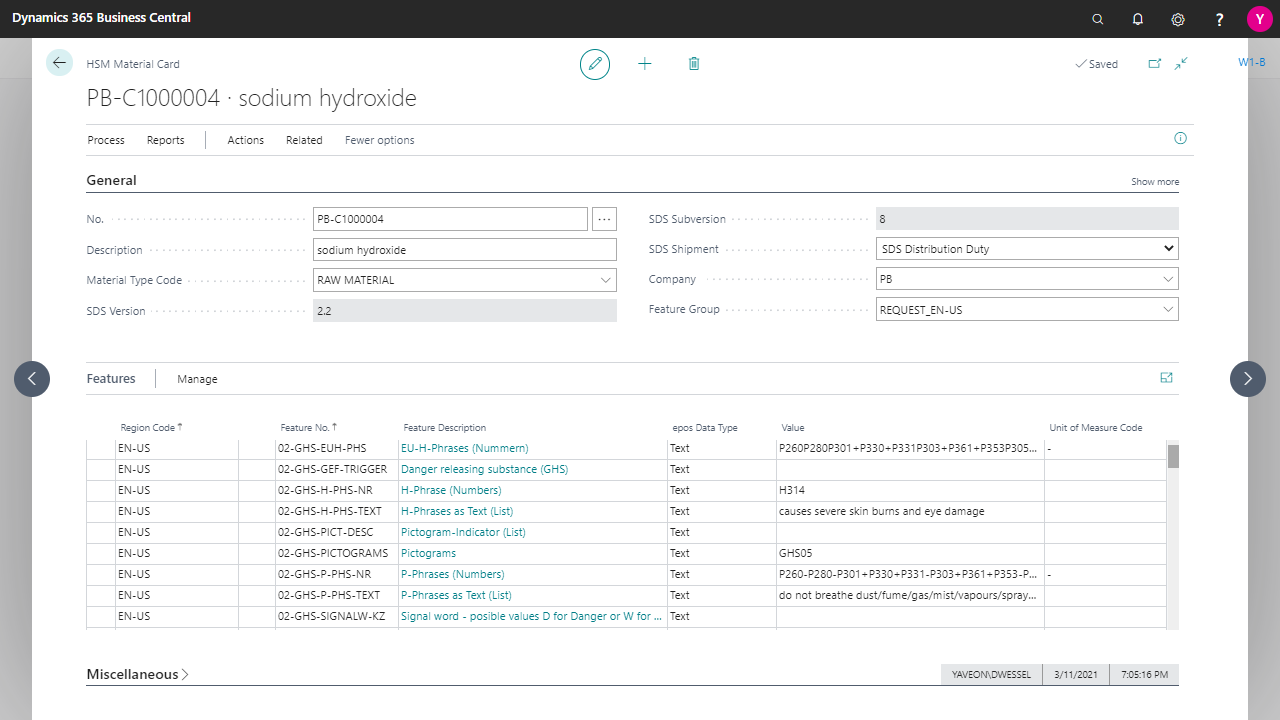

Manage safety data sheets

Maintain fire brigade lists

Organize hazardous materials storage efficiently

Control dangerous goods transport safely

Yaveon 365 is specifically designed for the unique needs of the chemical industry and offers a wide range of features to streamline your daily operations and optimize your business processes. These features include:

An ERP software specifically designed for the chemical industry offers much more than just process optimization. It sustainably increases efficiency and ensures reliable compliance with legal requirements like REACH. Such a system not only aids in the management of hazardous substances and traceability but also in the precise development of recipes. Particularly helpful are the real-time data analyses that enable informed decision-making and promote sustainable production. In short, this kind of ERP solution is the key to enhanced safety, efficiency, and innovation in the chemical industry.

Implementing an ERP system in chemical companies involves unique challenges: flawless data migration, targeted training, and business process adaptation. Our chemical industry ERP solution and the proven project methodology “ProCedures” support you from planning to implementation—effectively, systematically, and practically.

The costs associated with implementing and maintaining an ERP system vary based on your company's size, the chosen software solution, the degree of customization, and required functionalities. Total costs comprise one-time implementation charges and ongoing expenses for updates, support, and training. Detailed cost planning assists in efficiently setting a budget while considering all necessary requirements.

Yes. In addition to our extensive online help, we offer a selection of training videos to make getting started with our chemical industry software as easy and enjoyable as possible for all users. Our materials are designed to provide long-term support for you and your team, ensuring confidence in using the software.

Innovation is at the core of Yaveon. Together with Microsoft, we consistently provide you with the latest updates, ensuring you stay at the forefront of technology. We support you in future-proofing and advancing your processes.

How to manage hazardous materials safely – Beitrag öffnen

How to manage hazardous materials safely – Beitrag öffnen

Meeting hazardous materials regulations and securing your processes – made easier with ERP

How to manage hazardous substances safely – Beitrag öffnen

How to manage hazardous substances safely – Beitrag öffnen

How modern ERP systems make hazardous substance management efficient and easy to handle.

Recipes & characteristics in chemical production – Beitrag öffnen

Recipes & characteristics in chemical production – Beitrag öffnen

Future-proof chemical production: precise recipes, controlled characteristics, version control, and seamless lot tracking.