A food audit involves the inspection of manufacturing, processing and distribution processes in the food industry for quality assurance purposes.

Efficient processes: automated workflows save time and reduce errors

Specialized Industry Knowledge: ERP developed with food producers

Full transparency: Supply chain data for informed decision-making

Setup item tracing

Management of batches and serial numbers

Rule management for product labels with posting rule groups

Import of inventory

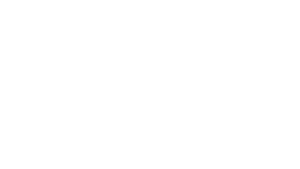

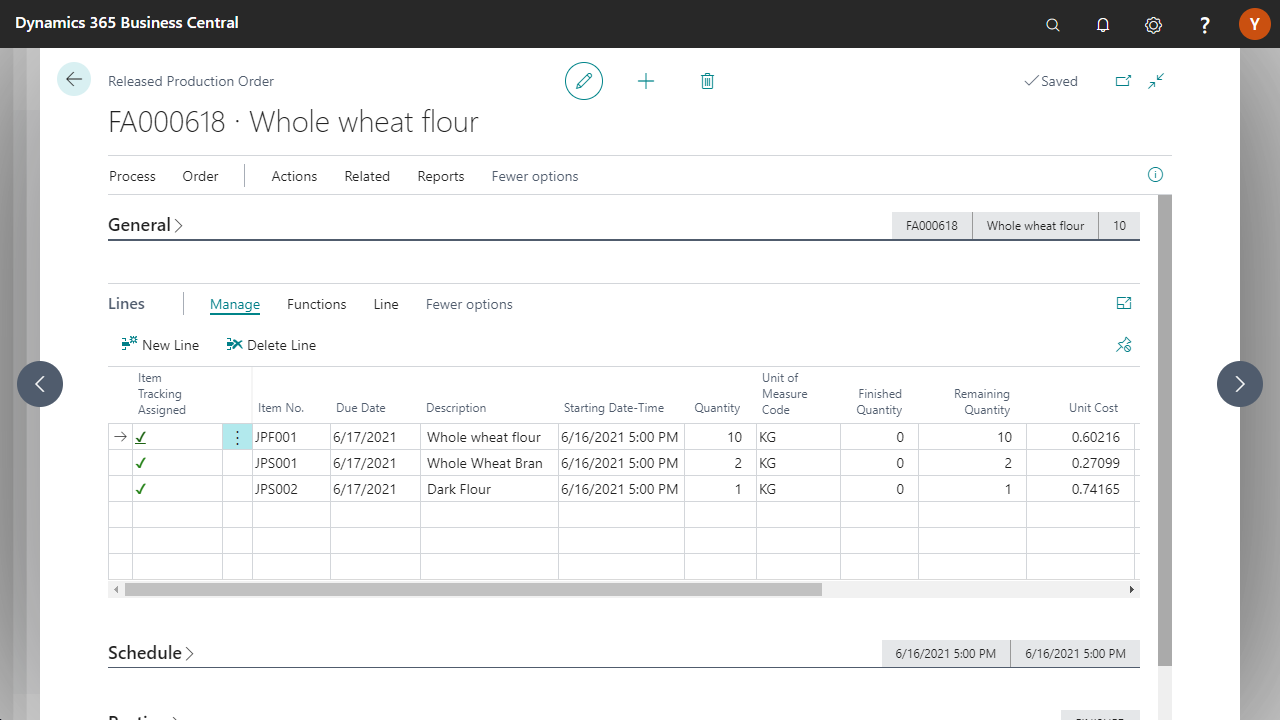

Creating manufacturing instructions

Batch inheritance in production

Consumption posting using FIFO/FEFO

Multi-level feature calculation

Configuring master data

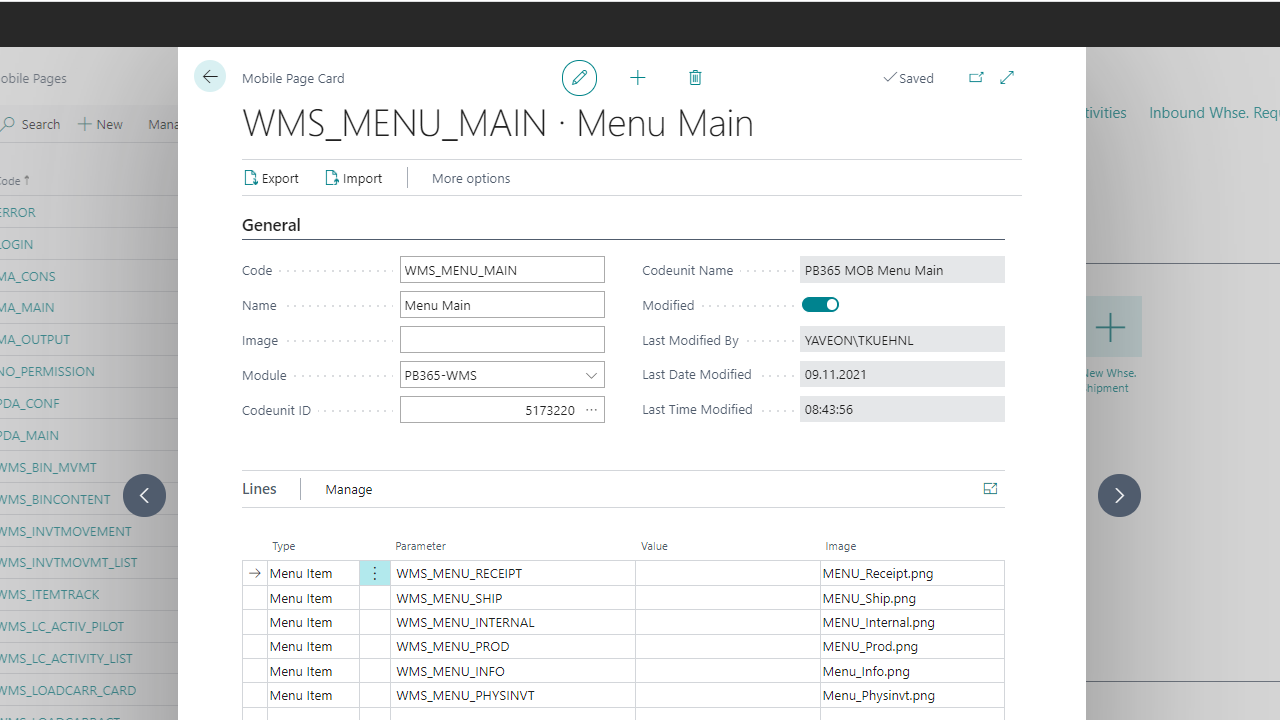

Automatic provisioning of authorization sets

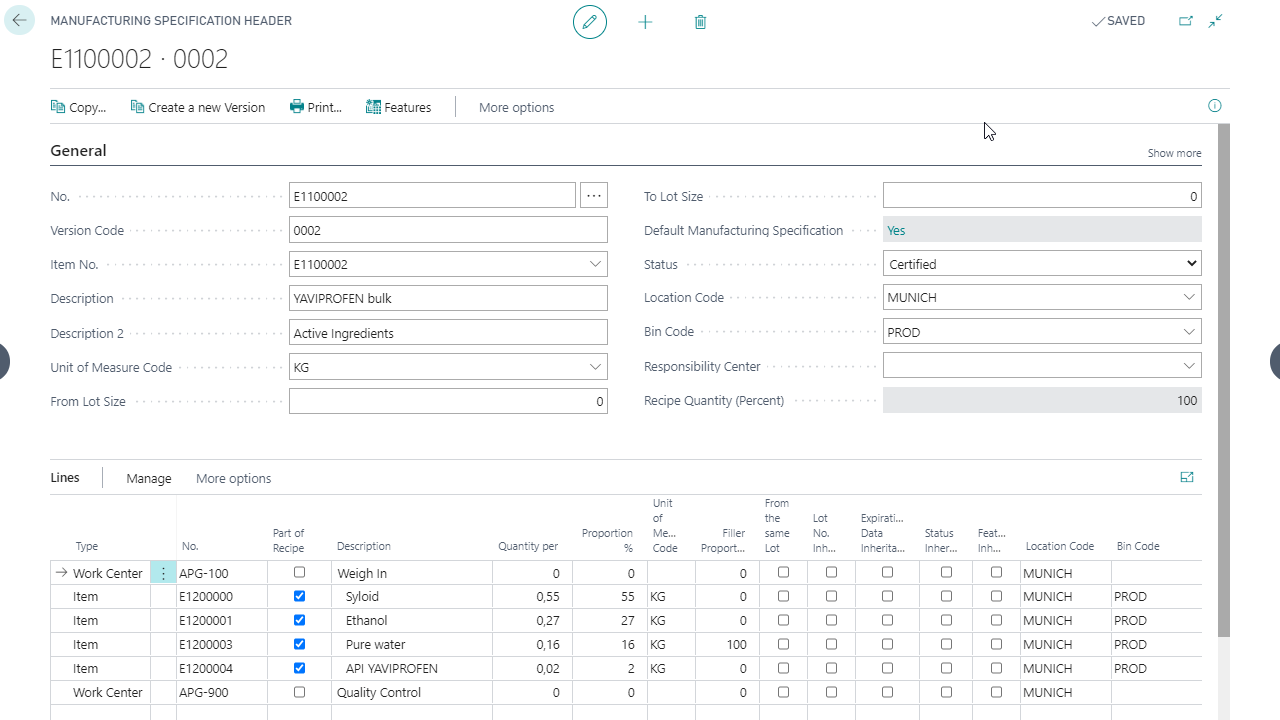

Creating inspection methods

Definition and execution of inspection orders

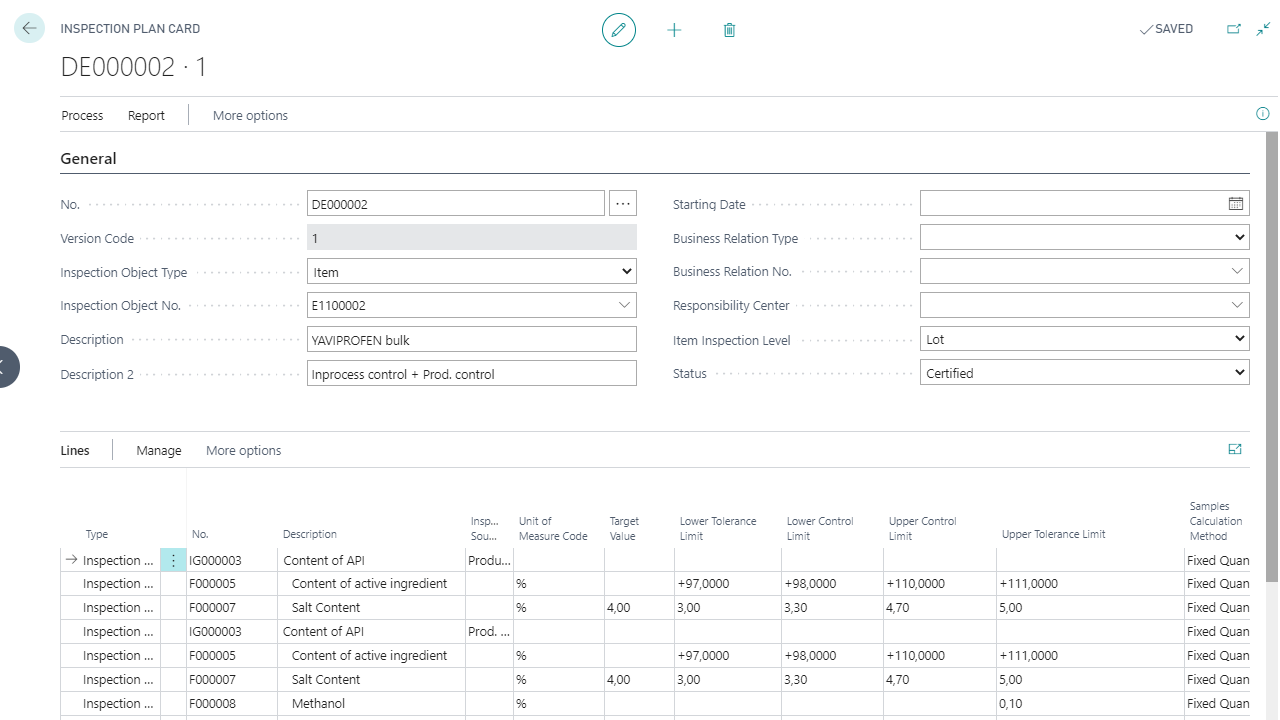

Preliminary costing for item costs and prices

Costing groups as a basis for costing schemas

Creating item cost value names

Calculation of item costing

Basis for valid cost allocation

Provision of permission sets

Document the byproducts in the production formula

Production orders with joint production

Warehouse receiving dialogs

Transfer orders

Report actual and consumption data for production

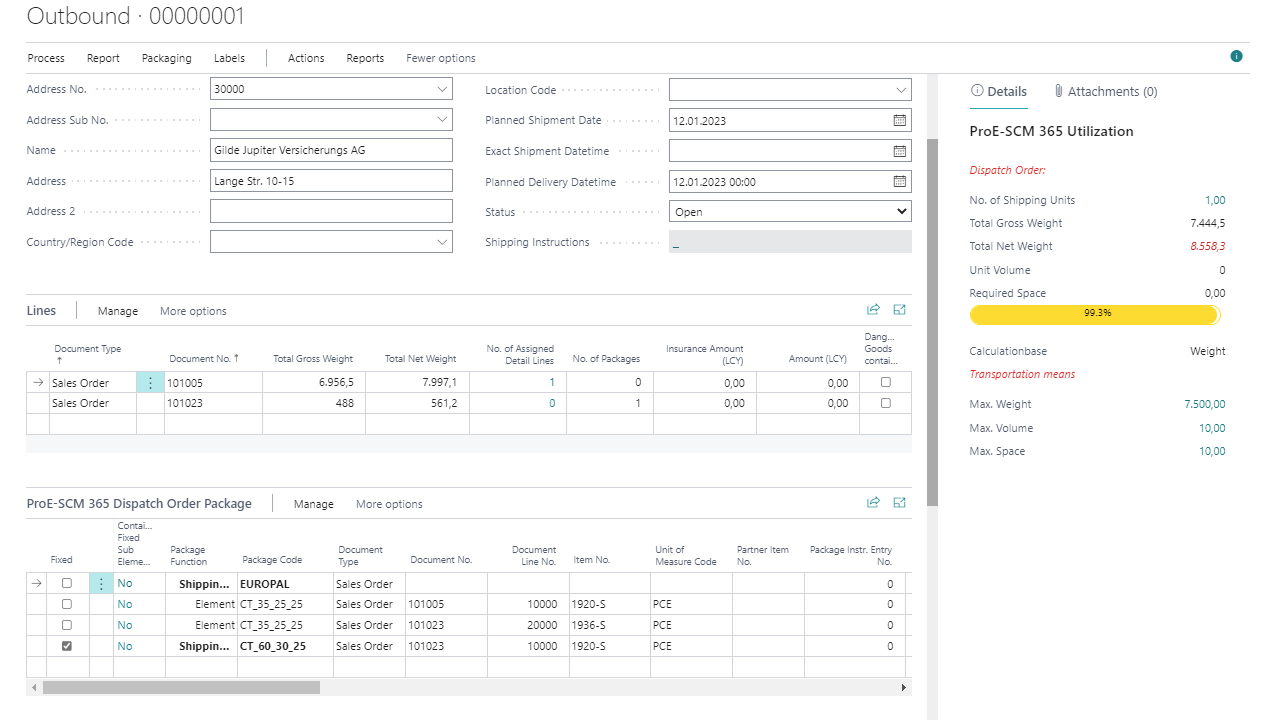

Order picking dialogue in warehouse shipping, including packaging structure

Default settings for new shipment orders

Definition of packaging material types

Setting up delivery suggestions

Creation of shipment orders using shipping schemes

The Yaveon ERP software for the food industry is designed to streamline and enhance transparency in this demanding sector. Tailored specifically for food companies, it optimizes critical business areas such as procurement, production, sales, and distribution. With a focus on efficiency and the highest safety standards, it aids in resource planning, production control, and regulatory compliance. Real-time data analysis enhances transparency, minimizes errors, and ensures product quality.

Our ERP system is perfectly tailored to meet the needs of food companies. With features like traceability throughout the supply chain, detailed batch management, and integrated quality inspections, you can consistently ensure quality and compliance with all legal requirements. Flexible production scheduling, management of best-before dates, and HACCP monitoring are also integrated. With Yaveon, you create efficient, compliant processes and a future-proof production chain that grows with the demands of your industry.

Yaveon's ERP software for the food industry optimizes processes, enhances food safety, and ensures supply chain transparency. Features like automated processes, precise best-before-date monitoring, and optimized production scheduling reduce errors and increase efficiency. Based on Microsoft Dynamics 365 Business Central, it offers a familiar design for easy adoption.

Implementing an ERP system in the food industry demands precise planning and expertise. We support you with our proven ProCedures methodology, secure data migration, and industry-specific customizations. Hands-on training ensures your team uses the system efficiently.

The costs associated with implementing and maintaining an ERP system vary based on your food company's size, the chosen software solution, the degree of customization, and required functionalities. Total costs consist of one-time implementation fees as well as ongoing expenses for updates, support, and training. Detailed cost planning will help you efficiently set your budget and consider all necessary requirements.

Yaveon 365 enhances food safety through product specifications, comprehensive traceability from raw materials to delivery, integrated quality control, and many other capabilities.

Everything about food safety audits – Beitrag öffnen

Everything about food safety audits – Beitrag öffnen

A food audit involves the inspection of manufacturing, processing and distribution processes in the food industry for quality assurance purposes.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

Quality control ensures that food always meets the highest standards of safety and quality through testing procedures and legal requirements.