Find out how you can regulate audit trails & electronic signatures, comply with FDA 21 CFR Part 11 & revolutionize your pharmaceutical release processes with the ERP industry solution.

Reduced complexity: for more flexibility

Audit-safe processes: complies with essential regulations

Controlled Supply Chain: seamless oversight and insights

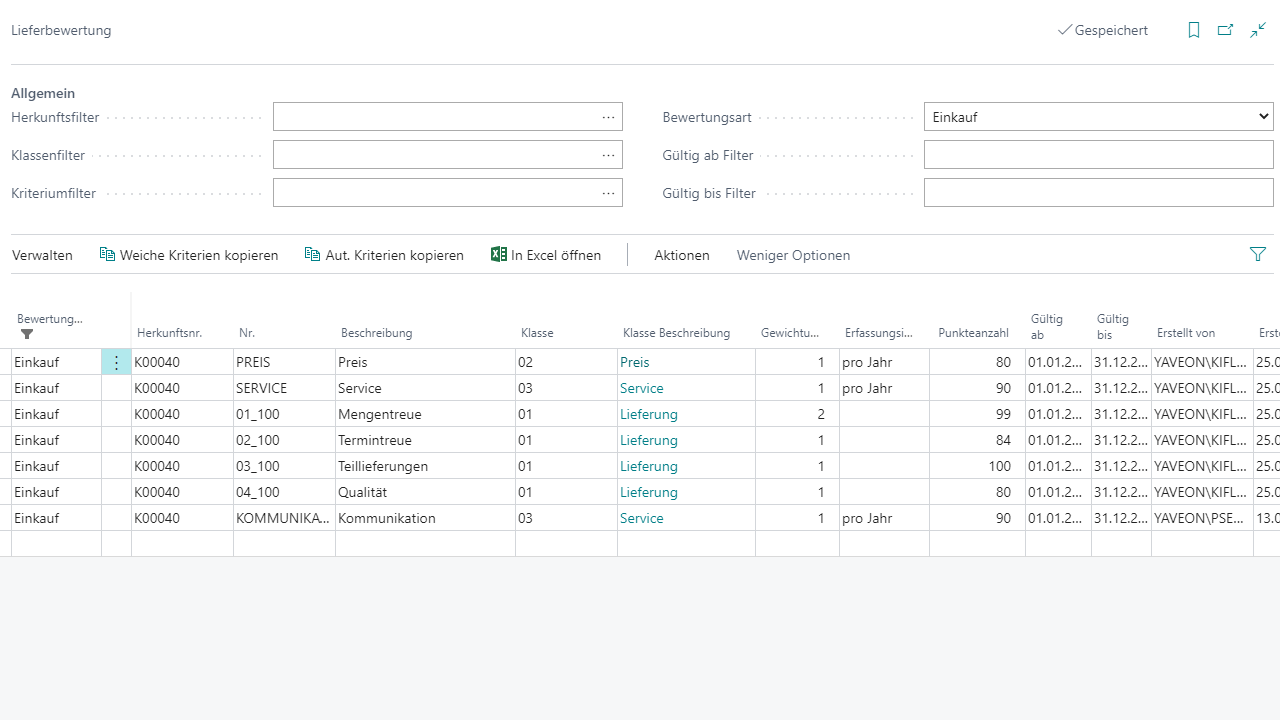

Internal & External Supplier Evaluation

Assigning evaluation criteria

Deadline reliability, quantity reliability & partial shipments

Creating reports based on automated criteria

Assigning permission sets

Electronic signature

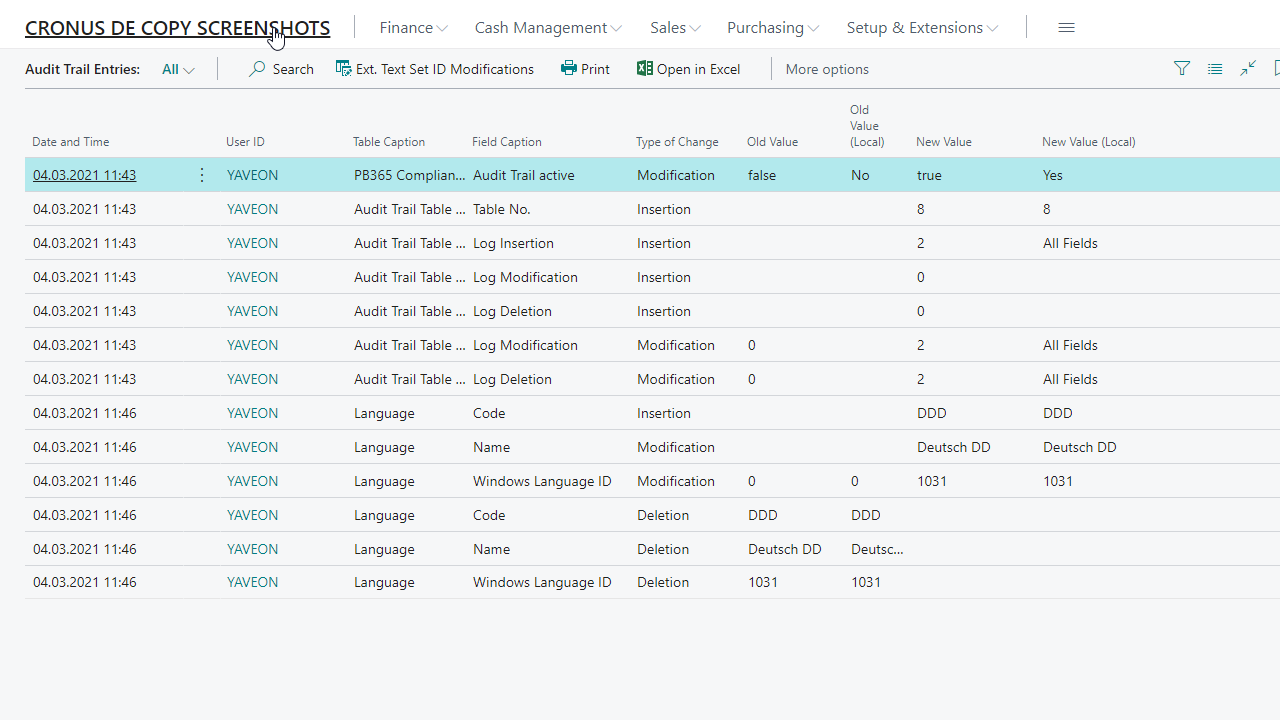

Tracking of database changes with the audit trail

Field security for user-dependent rights

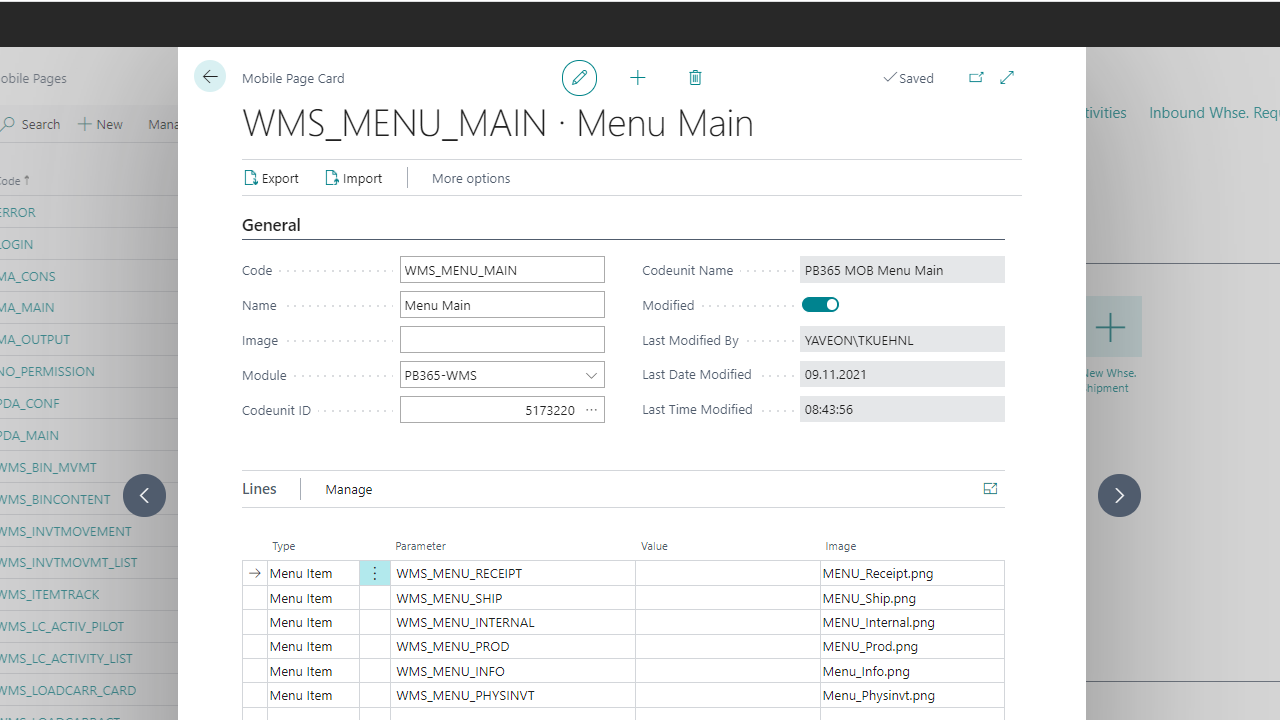

Warehouse receiving dialogues

Transfer orders

Report actual consumption and status for production

Order picking dialog in warehouse shipping, including packing structure

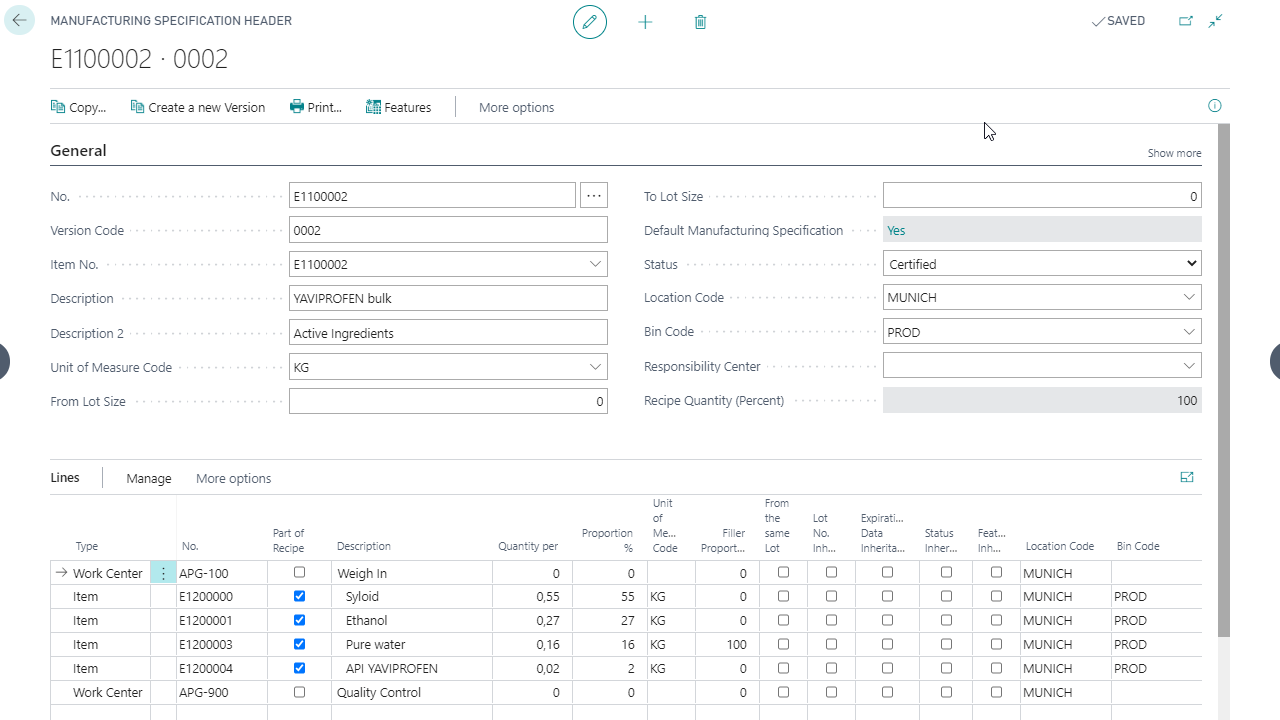

Setting up master data

Automatic provisioning of permission sets

Stability test orders & retention sample management

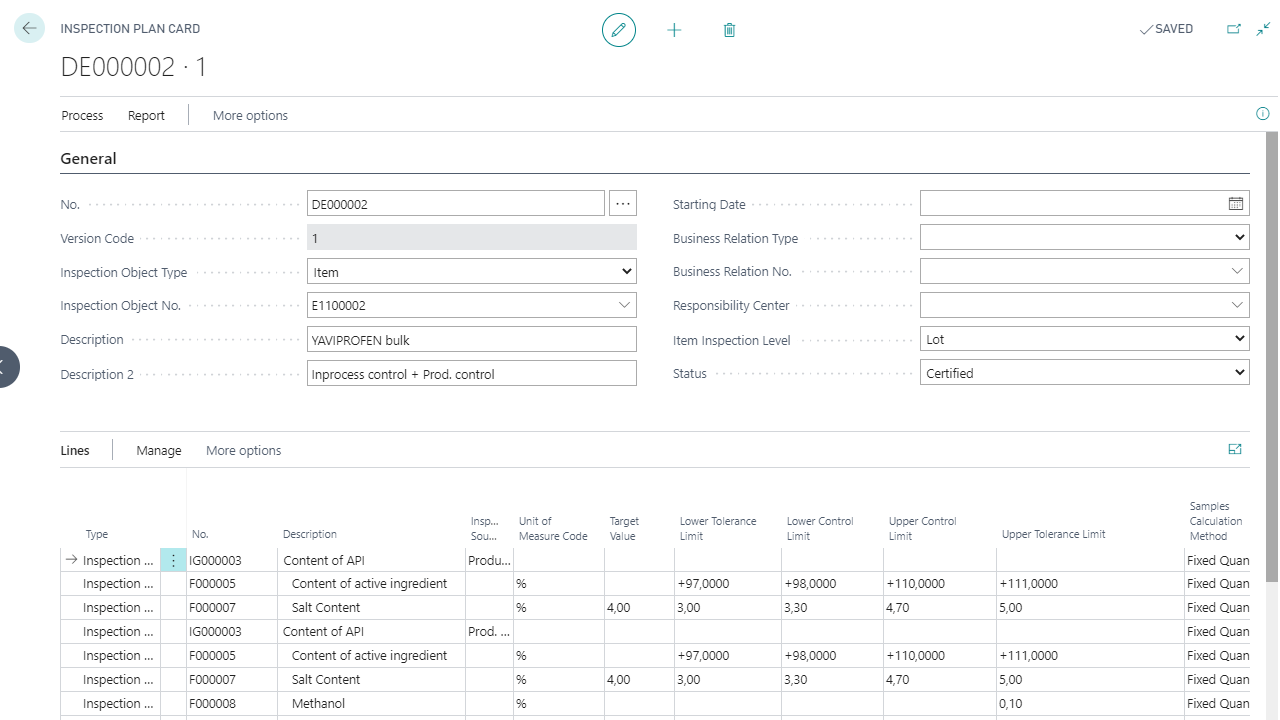

Definition and execution of inspection orders

Initialization of the inventory list

Automatic installation of permission sets

Creation of warehouse receiving, storage, and shipment

Definition of the pick order

Creating manufacturing instructions

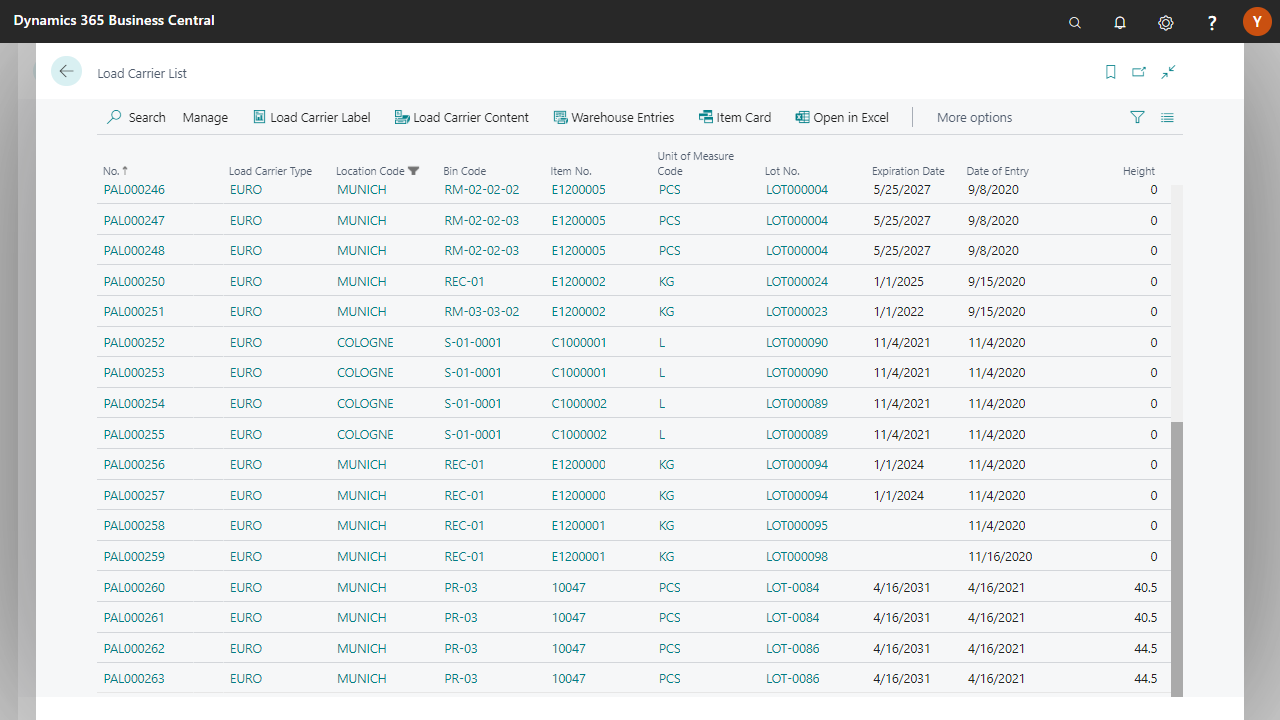

Batch inheritance in production

Consumption recording according to FIFO/FEFO

Multilevel feature calculation

Setting up item tracing

Management of batches and serial numbers (Traceability)

Rule management for product labels with posting rule groups

Multilevel batch release

Implementing ERP software in the pharmaceutical industry ensures compliance with GMP and FDA standards, guarantees traceability, and offers transparency. Production processes are optimized, resources are utilized more efficiently, costs are reduced, and automation minimizes errors. Integrated recipe management shortens development times and speeds up market entry. Companies gain efficiency and enhance their competitiveness.

With integrated features like comprehensive audit trails and seamless lot tracking, pharmaceutical ERP software ensures transparent and accurately documented processes. Additionally, validation consulting provides targeted support for creating essential documentation and processes to efficiently meet regulatory requirements. Specialized modules, such as those for formula and production scheduling, not only optimize internal operations but also ensure compliance with legal regulations throughout the entire manufacturing process.

Implementing an ERP system in the pharmaceutical industry requires precision and industry-specific expertise. Key challenges include regulatory requirements, system validation, and the integration of features such as lot tracking and quality control. With Microsoft Business Central and Yaveon 365, we offer a specialized solution. Our project methodology, ProCedures, ensures a structured and efficient implementation process. We place great emphasis on the secure migration of your data to ensure a seamless transition.

The costs for implementing and maintaining an ERP system vary based on the size of your pharmaceutical company, the chosen software solution, the degree of customization, and the required features. Total costs consist of one-time implementation expenses and ongoing costs for updates, support, and training. Detailed cost planning helps you allocate your budget efficiently and consider all necessary requirements.

Yes. In addition to our extensive online help, we offer a variety of training videos to ensure that all users can easily get started with the new pharmaceutical software. This ensures your team can work efficiently and seamlessly with the system.

Yes, absolutely. Together with Microsoft, we deliver continuous updates to ensure our software remains cutting-edge and meets your exact requirements. Our goal is to provide you with solutions that not only adhere to current standards but are also future-oriented and tailored to the unique needs of the pharmaceutical industry.

Audit trail & electronic signatures – Beitrag öffnen

Audit trail & electronic signatures – Beitrag öffnen

Find out how you can regulate audit trails & electronic signatures, comply with FDA 21 CFR Part 11 & revolutionize your pharmaceutical release processes with the ERP industry solution.

Success story: Hameln Pharma – Beitrag öffnen

Success story: Hameln Pharma – Beitrag öffnen

Read how hameln pharma connects an external warehouse largely with a standard interface and saves time through automated processes.

Success story: Midas Pharma – Beitrag öffnen

Success story: Midas Pharma – Beitrag öffnen

Read the report to find out how Midas uses a direct warehouse connection to the external logistics provider and processes orders automatically.