Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Full traceability: From raw materials to finished baked goods

Optimized supply chain: Seasonally adjusted & less waste

Highest compliance: Meets requirements of IFS, BRC & HACCP

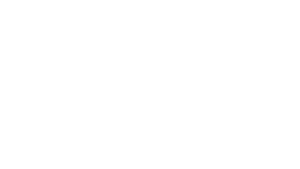

Management and costing of formulations

Integrated allergen management

Nutrition and cost calculation

Multistage production

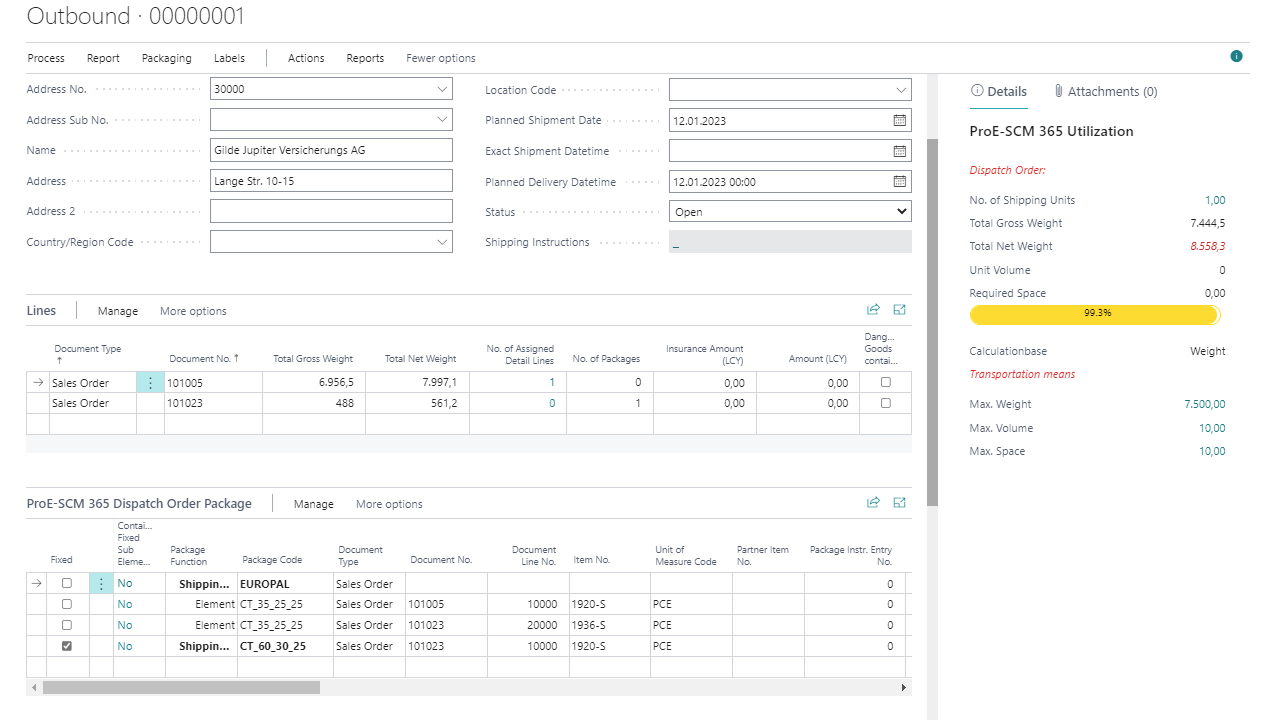

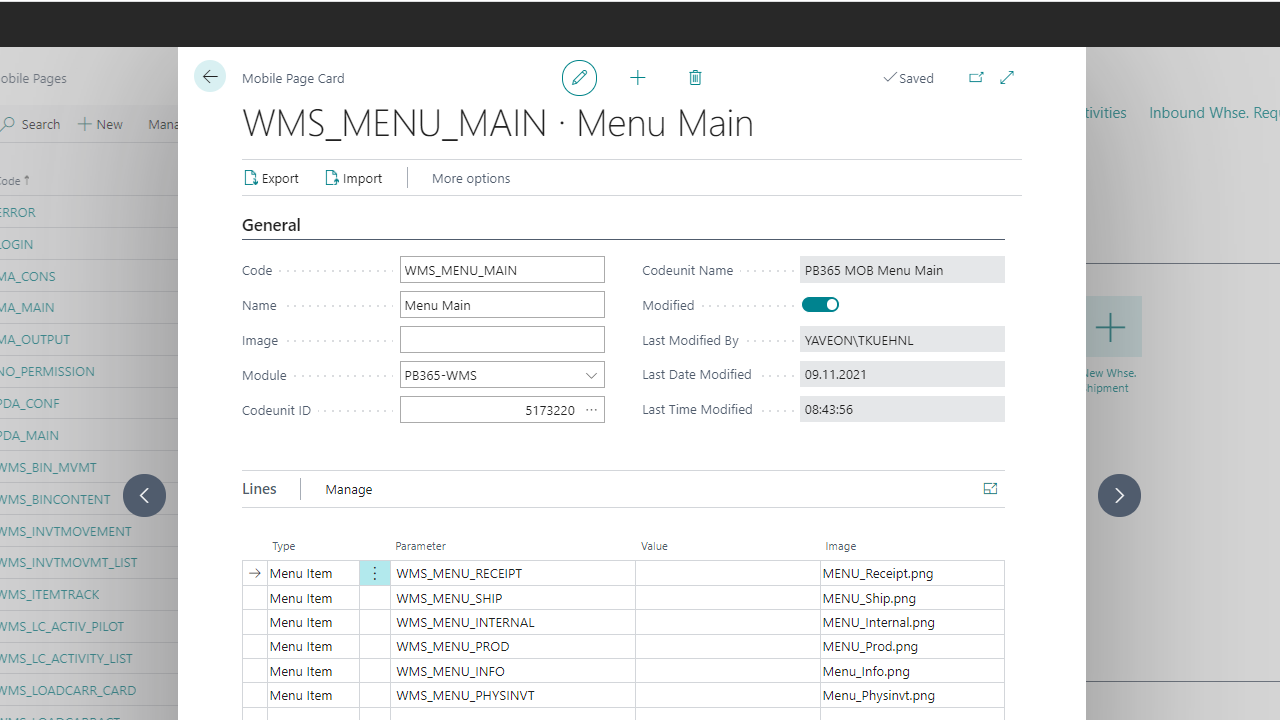

Real-time tracking of raw materials and finished products

Automatic shelf life monitoring

Recall lists at the push of a button

Integration into the warehouse management system

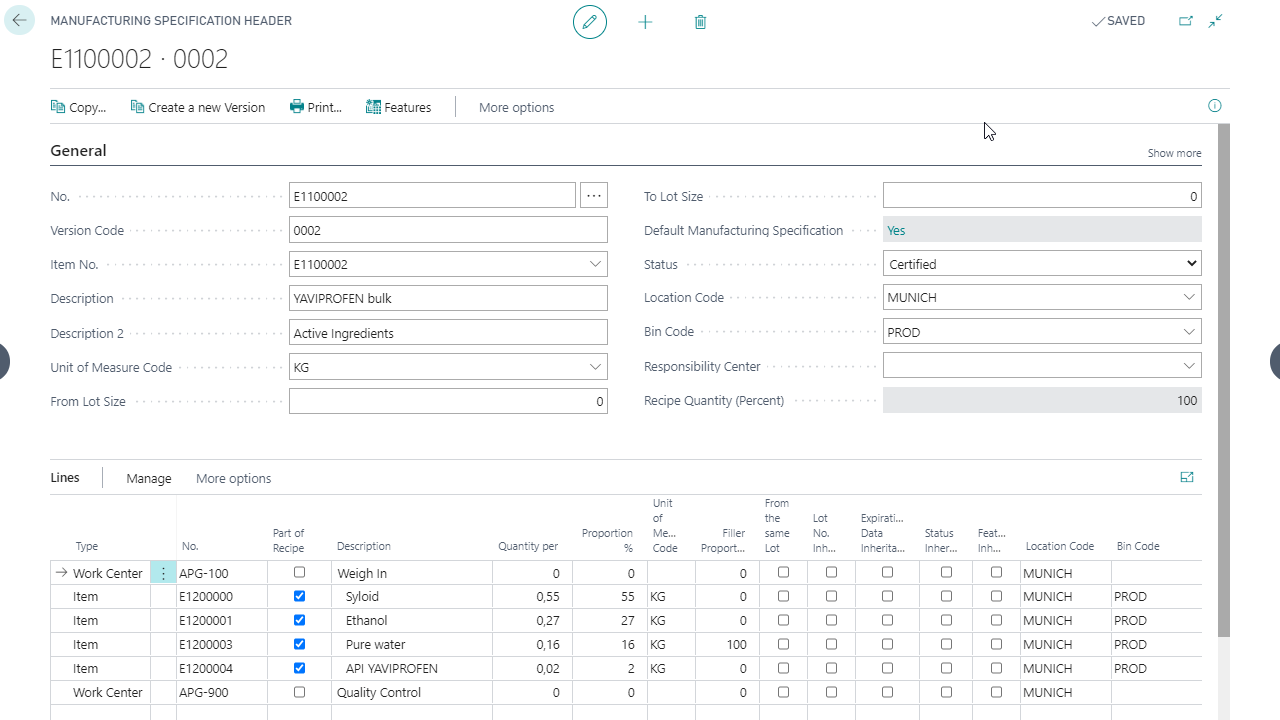

Test methods and inspection orders integrated into the system

Automated audit documentation

Direct connection with production and batch data

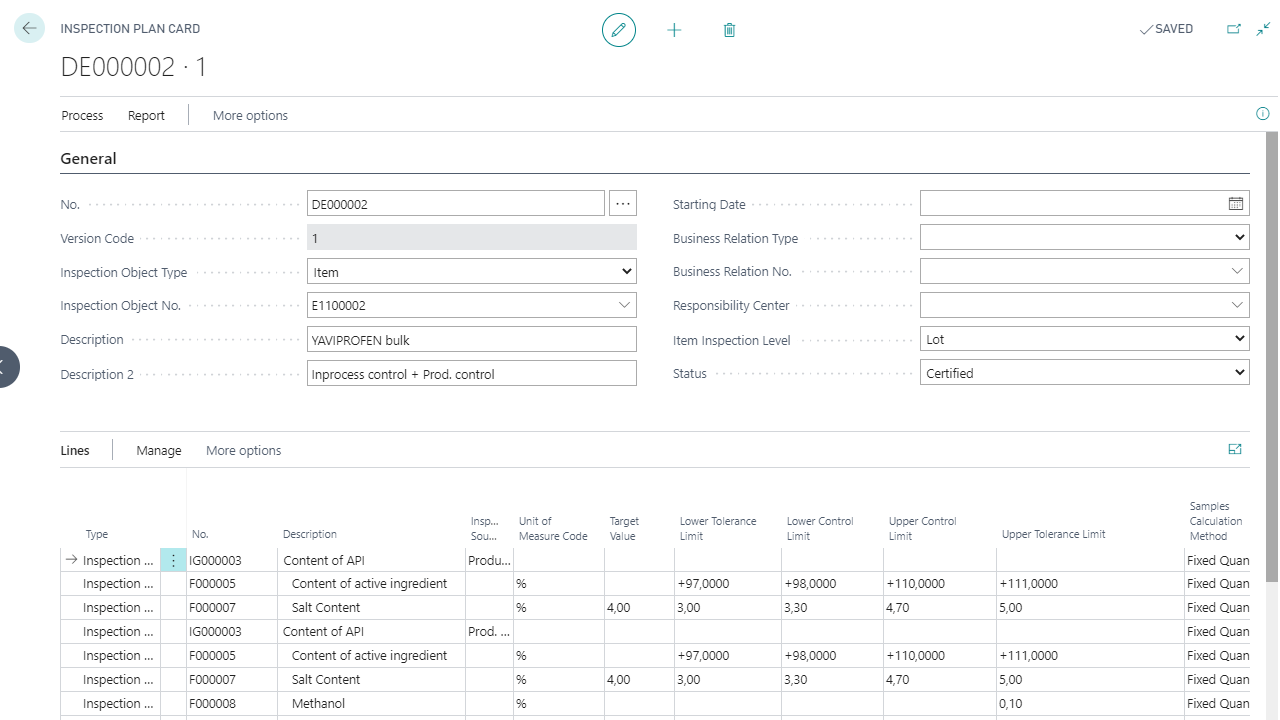

Seasonal capacity planning

Variants and joint production

Precise scheduling for reliable delivery commitments

Flexible container sizes

Compliant labeling

Internationally valid

Route planning for own trucks

Real-time inventory transparency

Error-free inventory postings

Optimize inventory based on shelf life

EDI with suppliers and the food retail sector

Our ERP software is the digital backbone for industrial baked goods manufacturers. It integrates formulation management, production scheduling, and distribution into a single solution, ensureing seamless process integration. The result: real-time insights, automated workflows, and a foundation for sustainable growth with the highest quality, customizable and scalable for your business.

Industry-specific features like batch and shelf-life management, allergen audits, flexible production scheduling, and nutrient and ingredient balance work seamlessly together. You remain compliant with IFS, BRC, and HACCP standards, producing with optimal efficiency even during seasonal fluctuations.

Our solution allows for precise planning of ingredient requirements and machine capacity. You can respond flexibly to fluctuating orders, avoid bottlenecks, and ensure timely deliveries without compromising on quality.

Accurate inventory management, optimized production scheduling, reduced waste, and data-driven cost control - this is how you reduce operational expenses and sustainably strengthen your profit margins. Additionally, our integrated reporting and analytics features provide the foundation for well-informed business decisions that propel your company forward.

You maintain oversight: From the delivery of raw materials to shipment, you seamlessly trace each batch. If a recall is necessary, the complete product history is available within seconds. Documenting quality inspections and reporting deviations occurs directly during the ongoing process.

Yes, Yaveon 365 grows with your company. New production lines, additional locations, international markets, or expanded features - the system adapts flexibly to your changing requirements and evolves alongside your success.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

5 tips how you can avoid recalls – Beitrag öffnen

5 tips how you can avoid recalls – Beitrag öffnen

Our paper provides 5 tips for the process industry: How to prevent recalls and ensure full batch traceability.