See how quality control keeps food safe and consistent through testing and regulatory standards.

Secure processes: Traceability from formulation to delivery

Transparent products: Allergen management & nutritional declaration

Flexible supply chain: For seasonal selections and variety

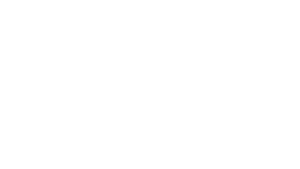

Management and costing of formulations

Automatic allergen declaration

Sugar tax and nutritional labeling

Transparent ingredient management

Comprehensive lot tracking

Best-before date and shelf life monitoring

Targeted recalls

Integration into warehouse and shipping processes

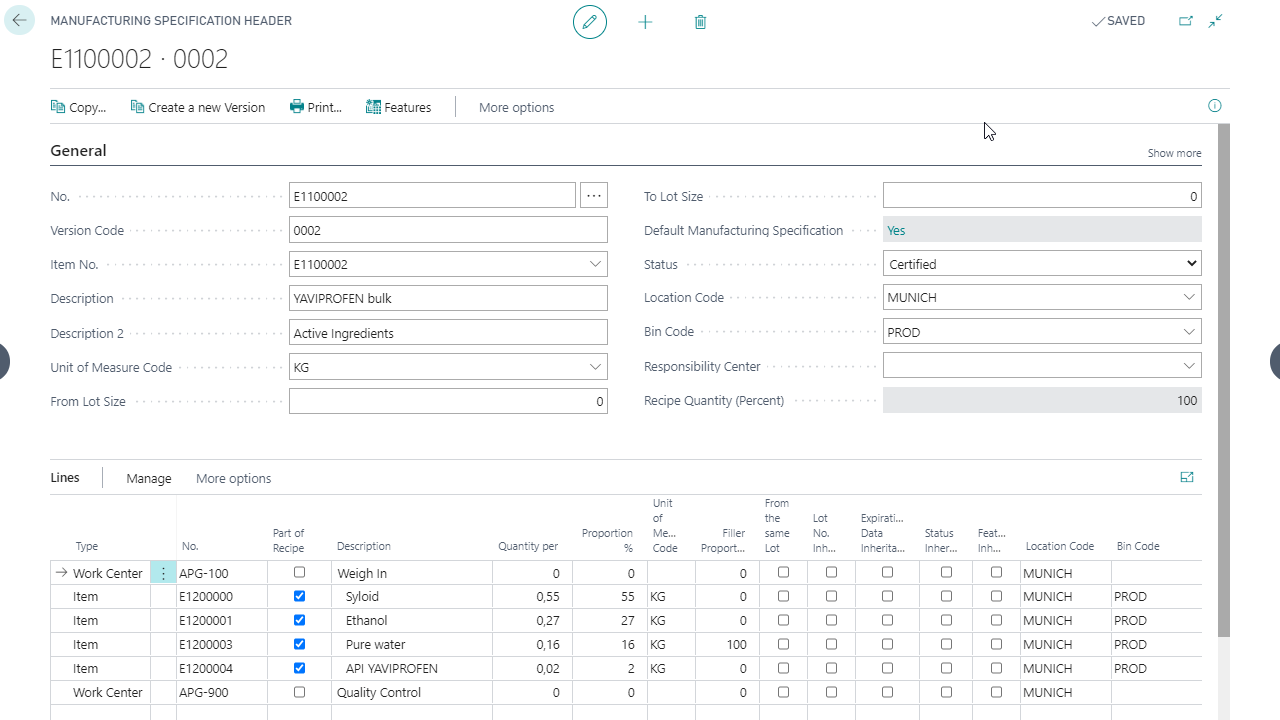

Consistency and moisture inspections

Taste tests and documentation

In-process controls in manufacturing

Incoming goods inspection of raw materials

Plan seasonal items reliably

Represent limited editions and variants

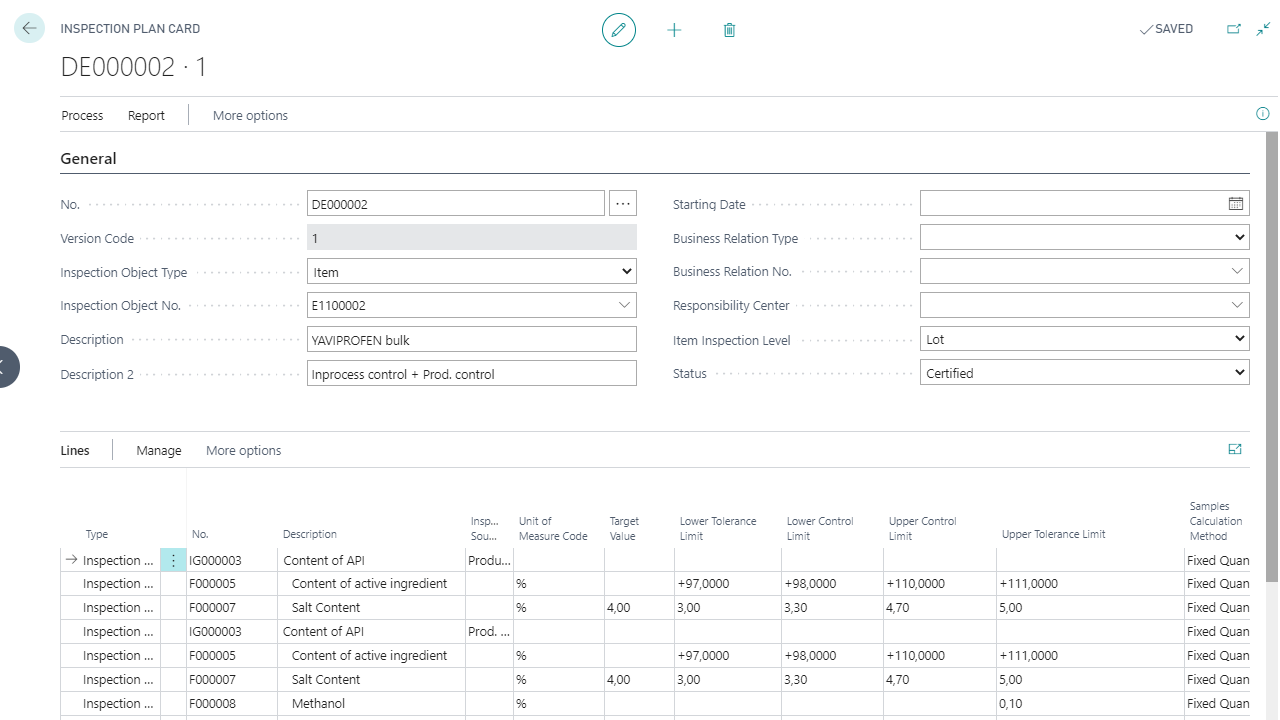

Manage flexible batch sizes

Resource and capacity planning

Optimized route planning

Major customer and export processing

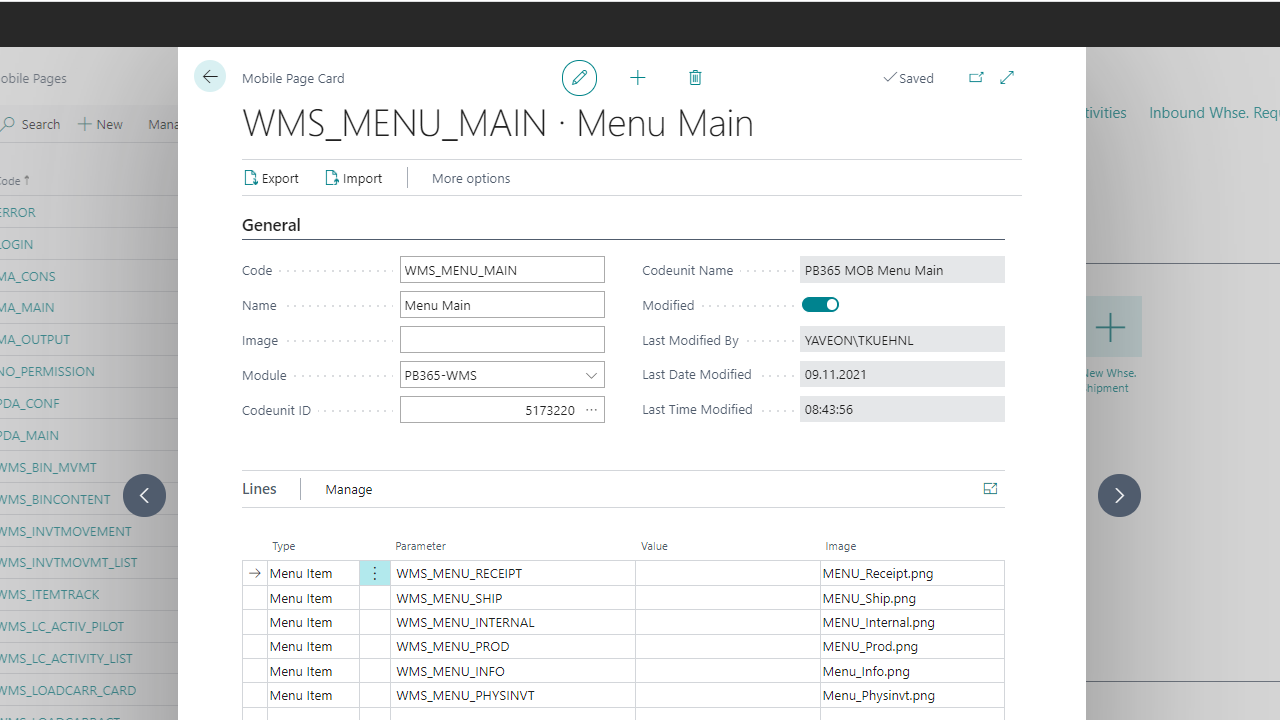

Integration with warehouse and ERP

Cost-optimized supply chains

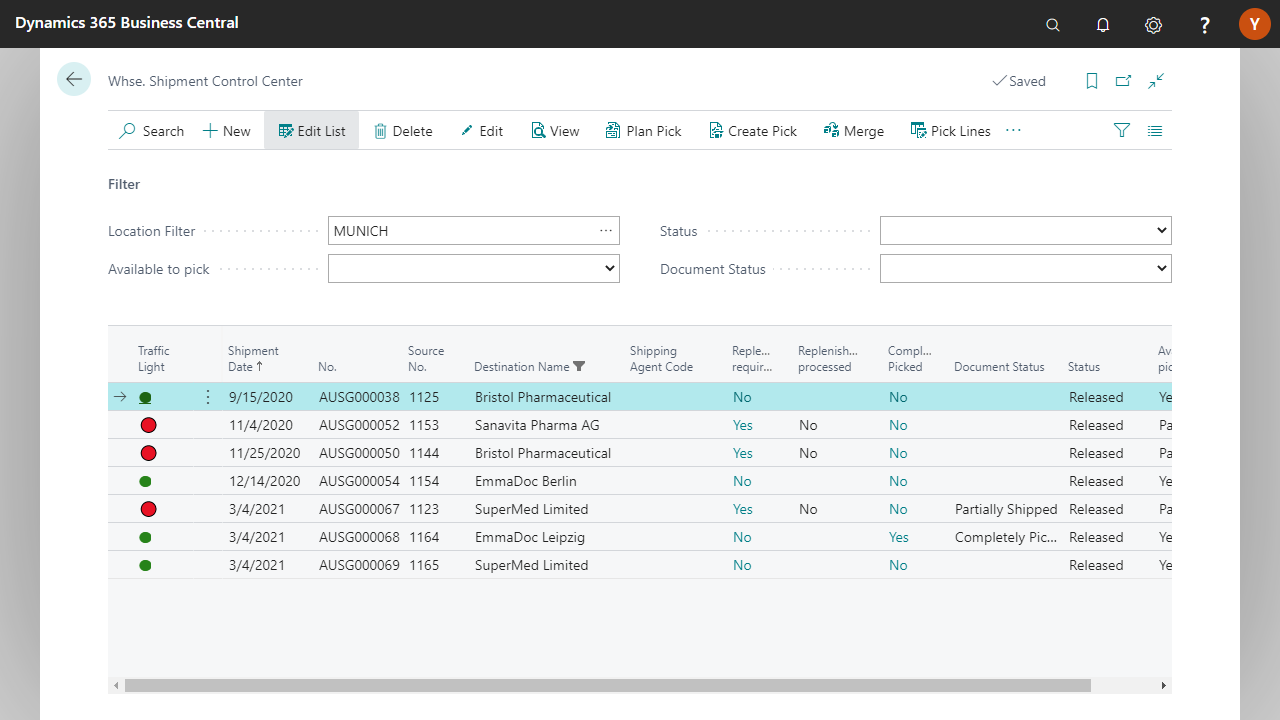

Mobile scanning solutions

Error-free warehouse postings

An overview of real-time inventories

Optimized shipping processes

Data reconciliation between shipments and invoices

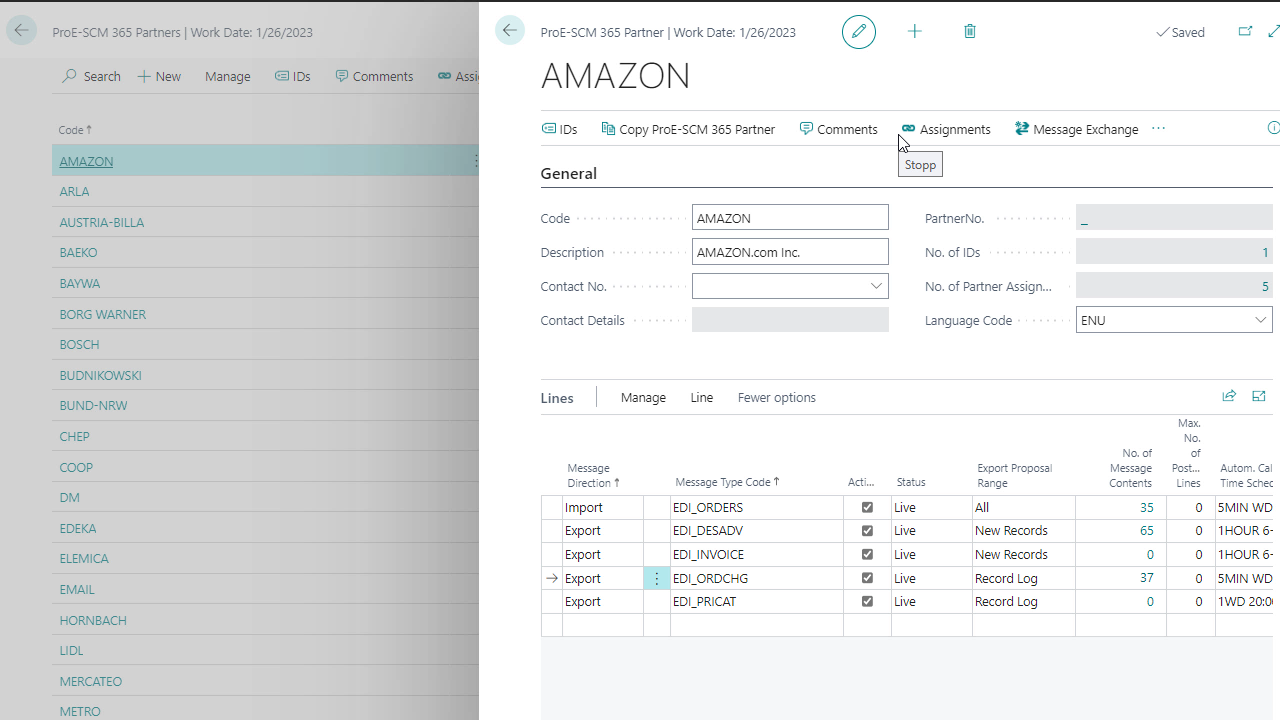

Transmission of purchase orders, invoices, & payment advice

Configuring discounts, surcharges, and credit notes

Import and central management of item catalogs

Flexible control through trade-related item groups

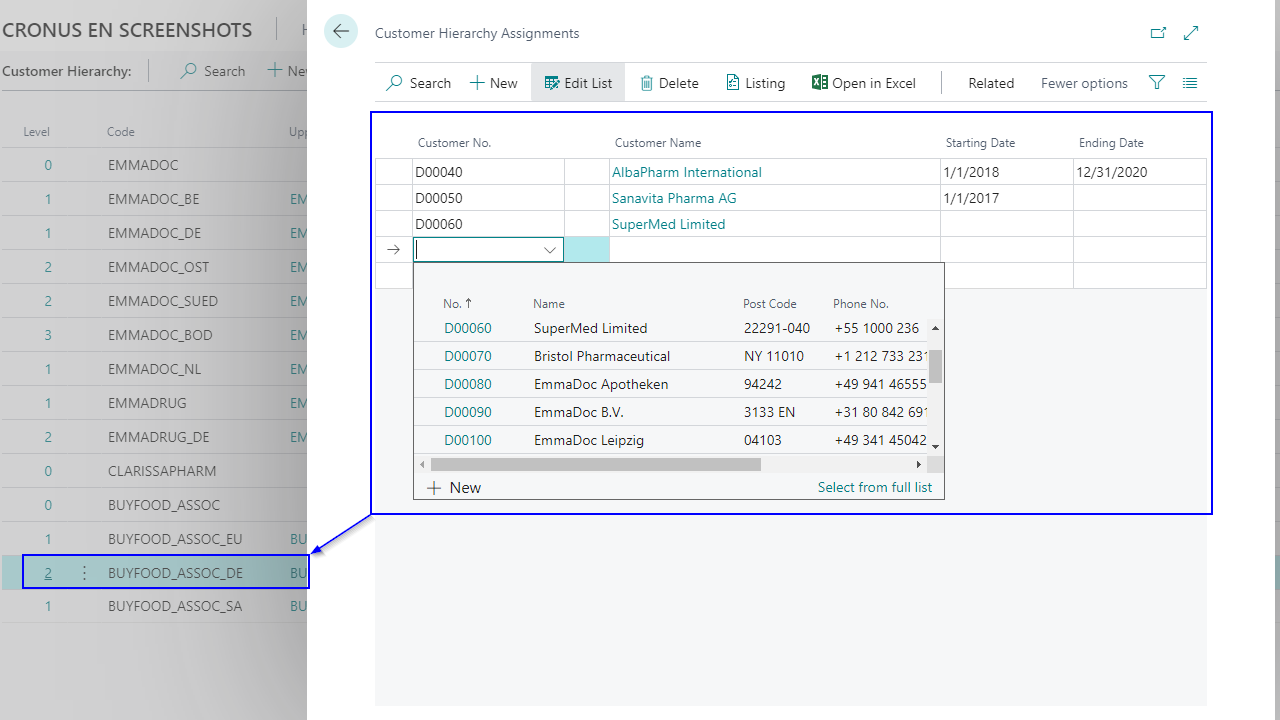

Transparent terms with a central price overview

Review of listings to prevent incorrect deliveries

Price and discount determination through customer hierarchies

All production steps, ingredients, and batches are centrally recorded and monitored. This ensures consistent product quality, meets HACCP, IFS, and BRC standards, and allows you to execute targeted recalls quickly when necessary.

Yaveon 365 enables precise planning of batch sizes, seasonal editions, and special packaging. Raw materials are optimally utilized to prevent bottlenecks and to flexibly adjust production to demand and season.

From order acceptance to delivery, all steps are automated: order confirmation, order picking, packaging, route planning, and shipment tracking. This ensures faster delivery times, reduced error rates, and a transparent supply chain.

The industry-specific ERP Yaveon 365 monitors expiration dates for different product types, manages warehouse rotation based on the FEFO principle, and prevents overstock and out-of-stock situations. Real-time warehouse data also ensures maximum transparency and efficiency.

With integrated production, packaging, and labeling planning, limited editions or seasonal assortments can be implemented without extra effort. Changes in design, packaging sizes, or ingredients are seamlessly integrated into ongoing processes.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

Supply chain management food industry – Beitrag öffnen

Supply chain management food industry – Beitrag öffnen

Optimise your food industry supply chain: boost efficiency and margins with the right ERP system.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.