See how quality control keeps food safe and consistent through testing and regulatory standards.

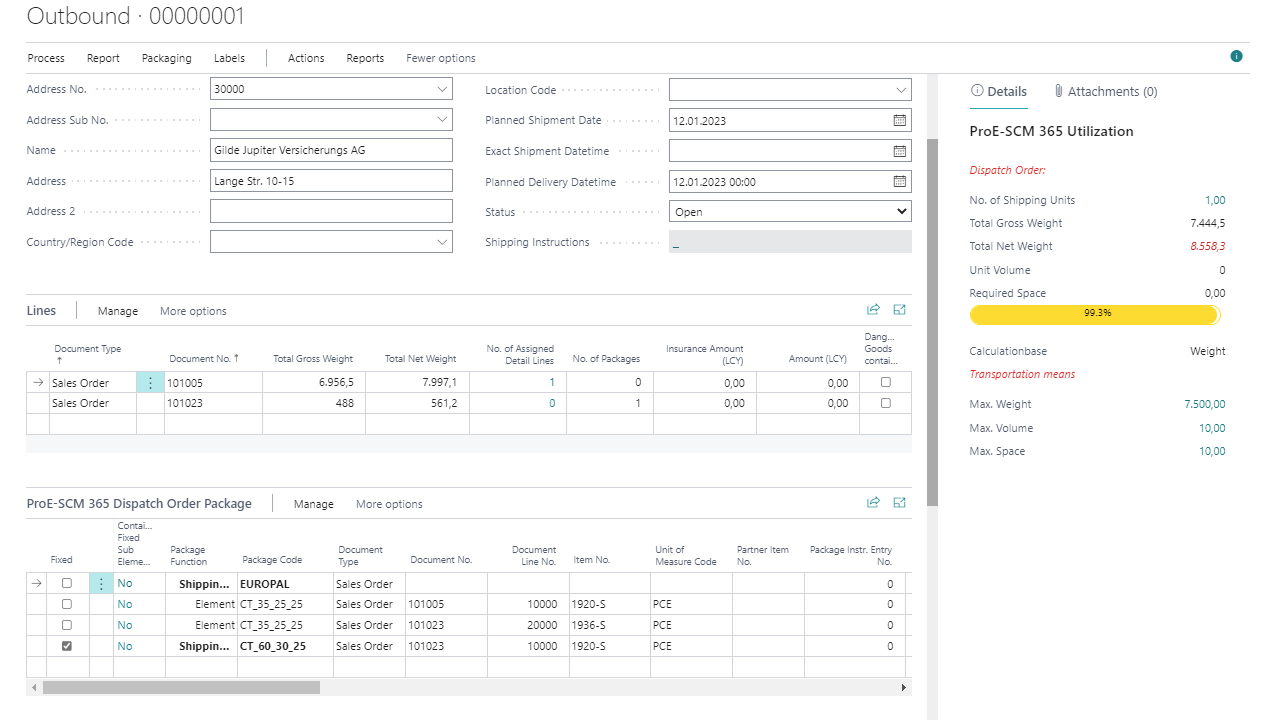

Complete traceability: From batch to shipment unit

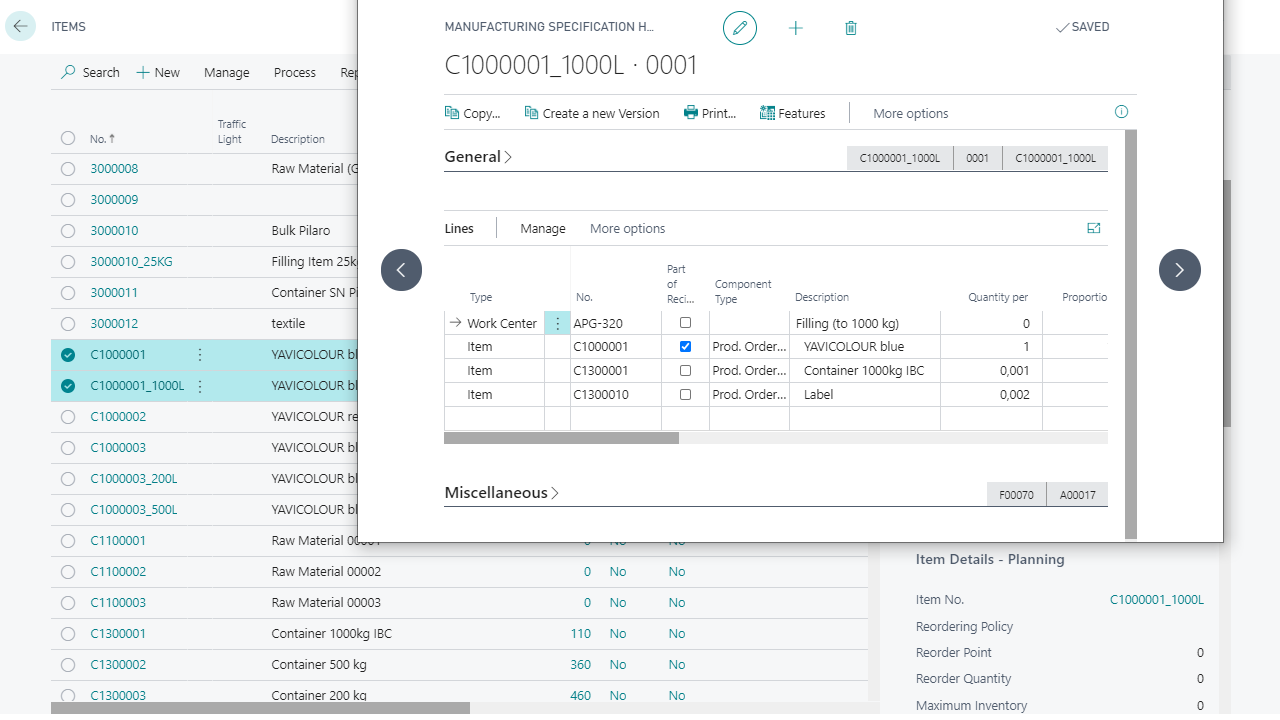

Top-notch safety: quality control with inspection plans & certificate of analysis

Satisfied customers: labeling, SSCC, and EDI

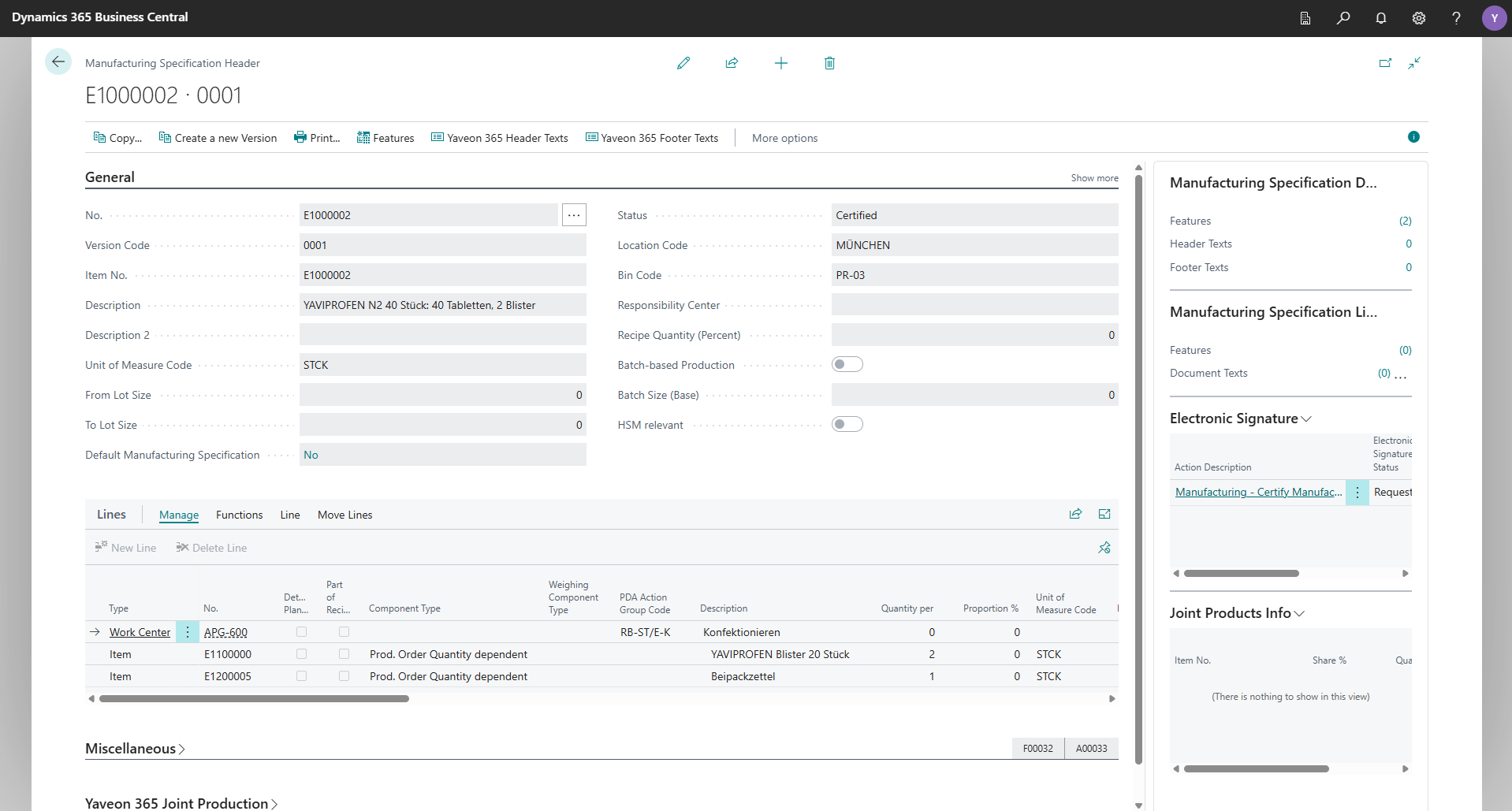

Multilevel bills of materials, preliminary/final costing

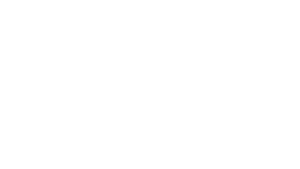

Versioning & approval workflow

Document target/actual consumption and losses

Derive label and declaration data from formulation

Advanced production scheduling & scenarios

Work plans per item and filling variant

Control of under/over-picking

Feedback & OEE-related KPIs

Inspection plans for raw materials & process steps

Deviation management & CAPA

Specification and compliance documents

COA recording & release

End-to-end batch management

Blocking reasons & quarantine

Origin, shelf life, inspection status

Forward/backward tracking

Warehouse & production logistics with mobile workflows

Labeling of packaging materials & containers

Custom shipping labels

Transport management & delivery receipts

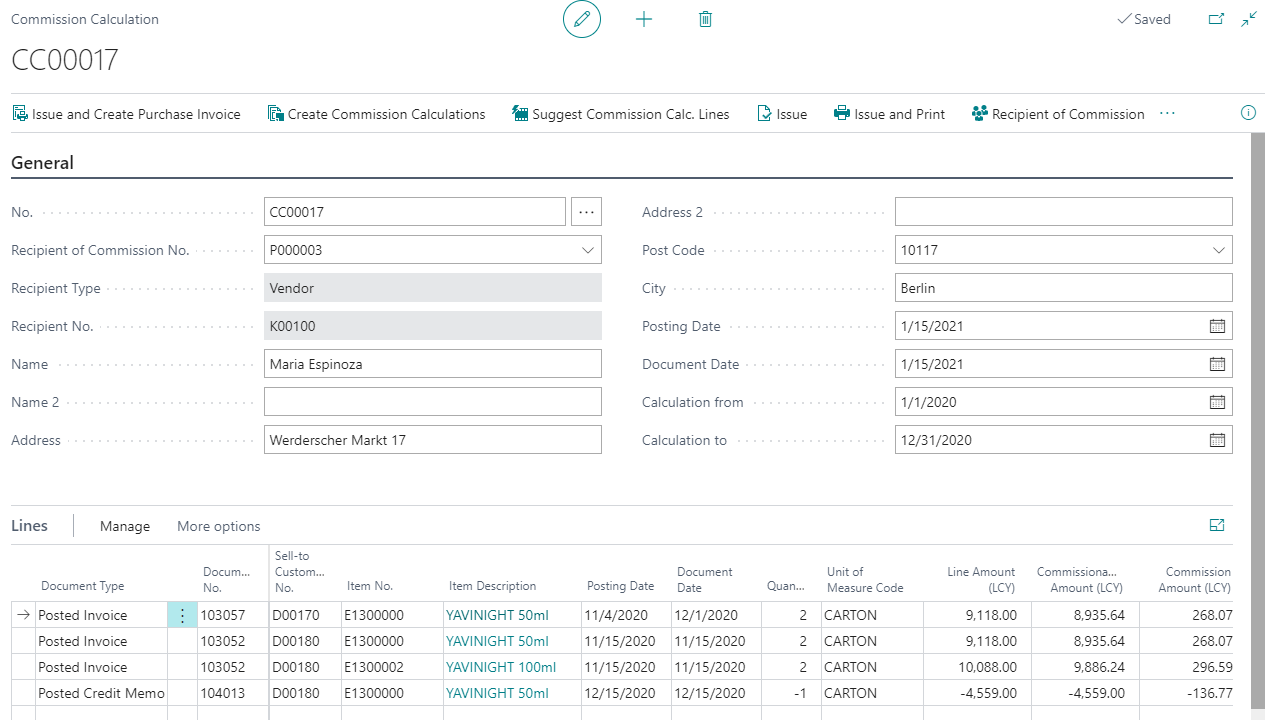

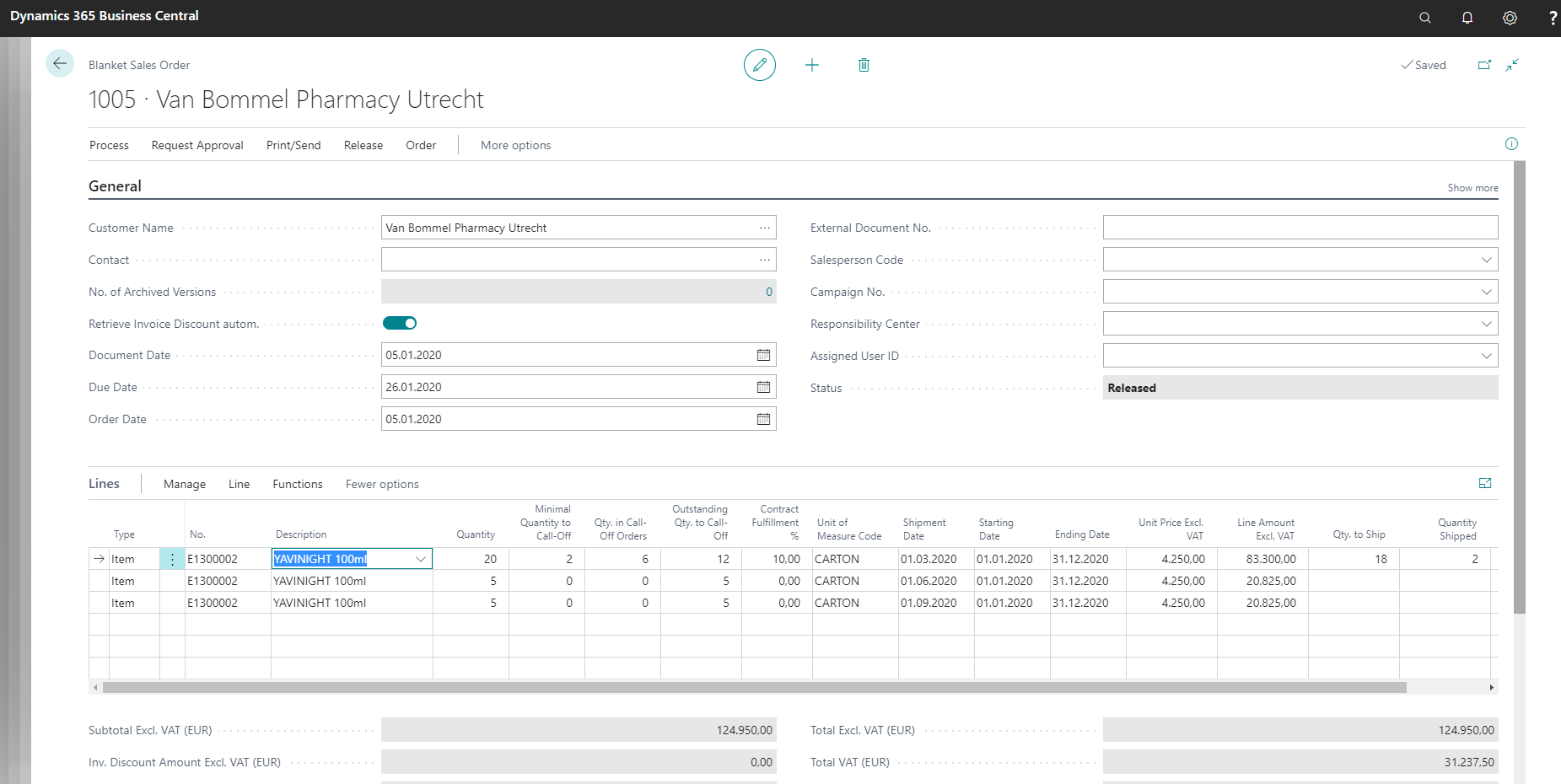

Volume pricing, terms & contracts

Customer/supplier item catalogs

Automated EDI documents

Contract & Trading Management

Vendor/supplier billing

Specification & certificate management

COA inspection as release criterion

Management of eco and consumption taxes

Yaveon 365 connects all batches from raw materials through filling, autoclaving, shipment, and palletizing into one solution. You can generate recall lists, blockages, and root cause analyses with complete traceability and audit security.

Our industry-specific ERP automatically captures time, temperature, and pressure parameters for each batch and links this information with releases. Deviations are systematically recorded and trigger locks, allowing you to demonstrate sterilization processes at any time.

Weighing feedback in Yaveon 365 precisely captures net fill volumes per batch or order. Additionally, trend controls and inspection plans detect overfills or underfills early, helping you comply with legal requirements.

Measurements and checklists for seam inspection on cans are stored in the system as steps for quality assurance. The results are saved by batch and order, serving as the basis for approvals and quality audits.

Labels from Yaveon 365 draw data directly from the formulation and specifications. Rules for shelf life and FEFO control warehousing and order picking, while can and pallet codes (e.g., SSCC) ensure clear identification in logistics.

The solution enables electronic data exchange directly from the system and integrates predefined conditions. SSCC, label variations, and contract logics ensure that you meet trade-related requirements automatically and accurately.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

Everything about food safety audits – Beitrag öffnen

Everything about food safety audits – Beitrag öffnen

Comprehensive guide to food safety audits that protects consumers and supports GFSI compliance.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.