Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Full traceability: From raw milk intake to delivery

Integrated processes: Integrated tank, silo, and production planning

Maximum safety: Meets requirements of IFS, BRC & HACCP

Collection of raw milk, fat/protein content, and temperature

Automatic tank assignment

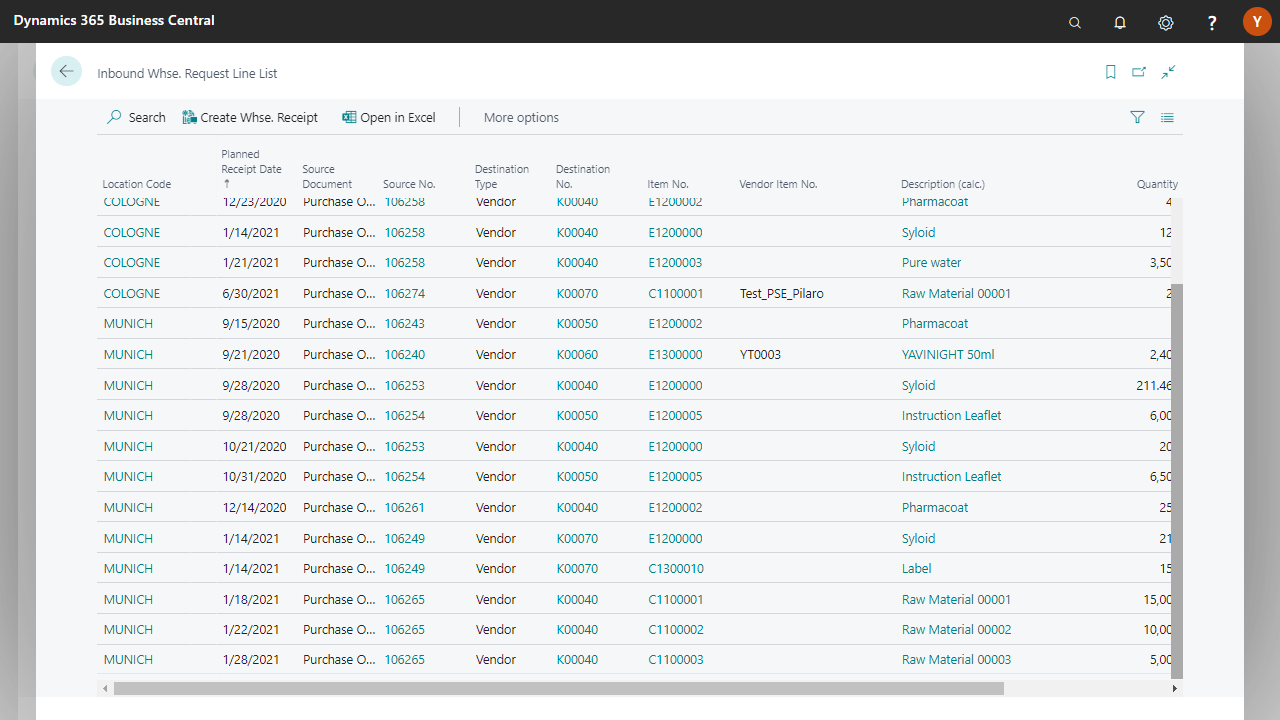

Digital documentation of all shipments

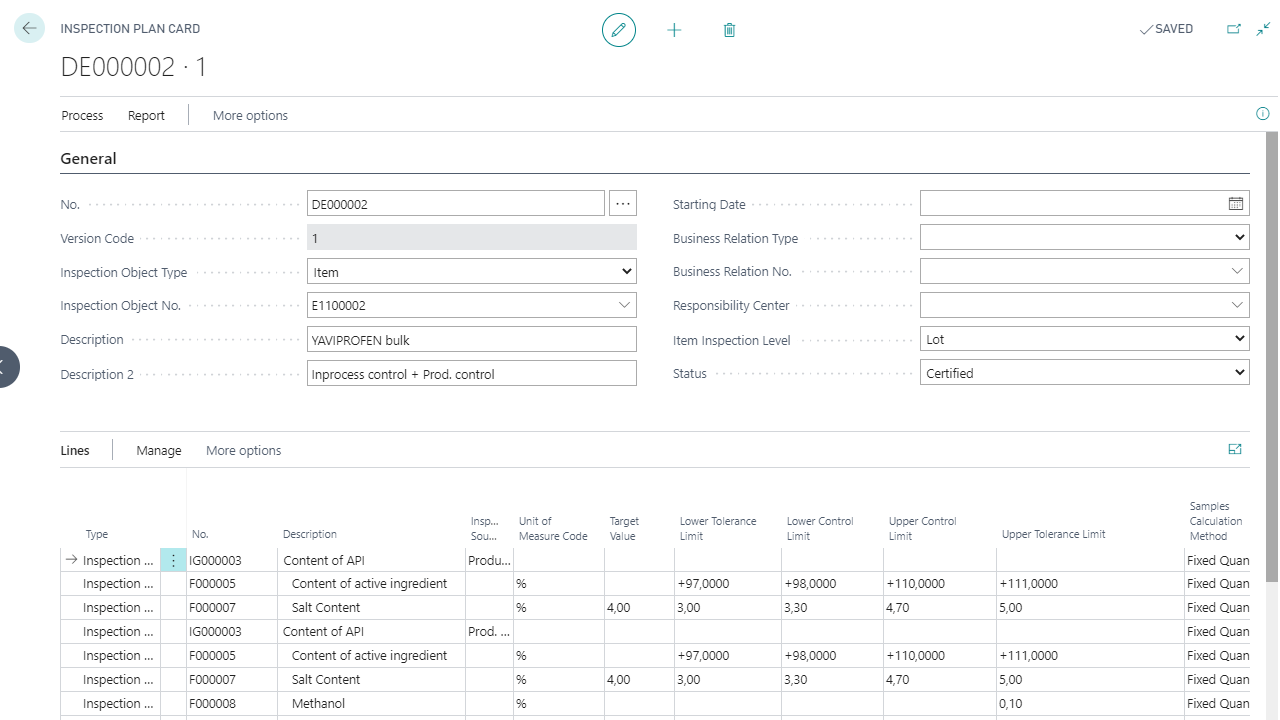

Integration into quality assurance systems

Maximum tank utilization

Planning for fresh milk, cheese, yogurt & milk powder

Seasonal production control

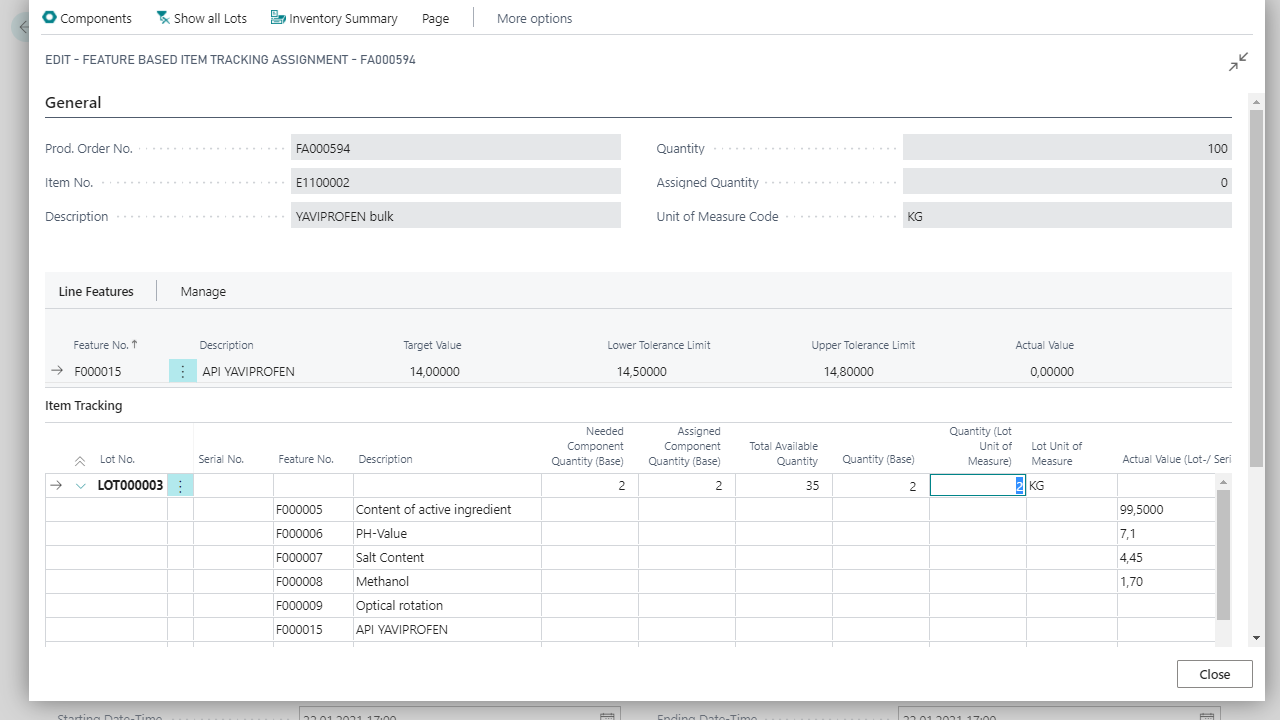

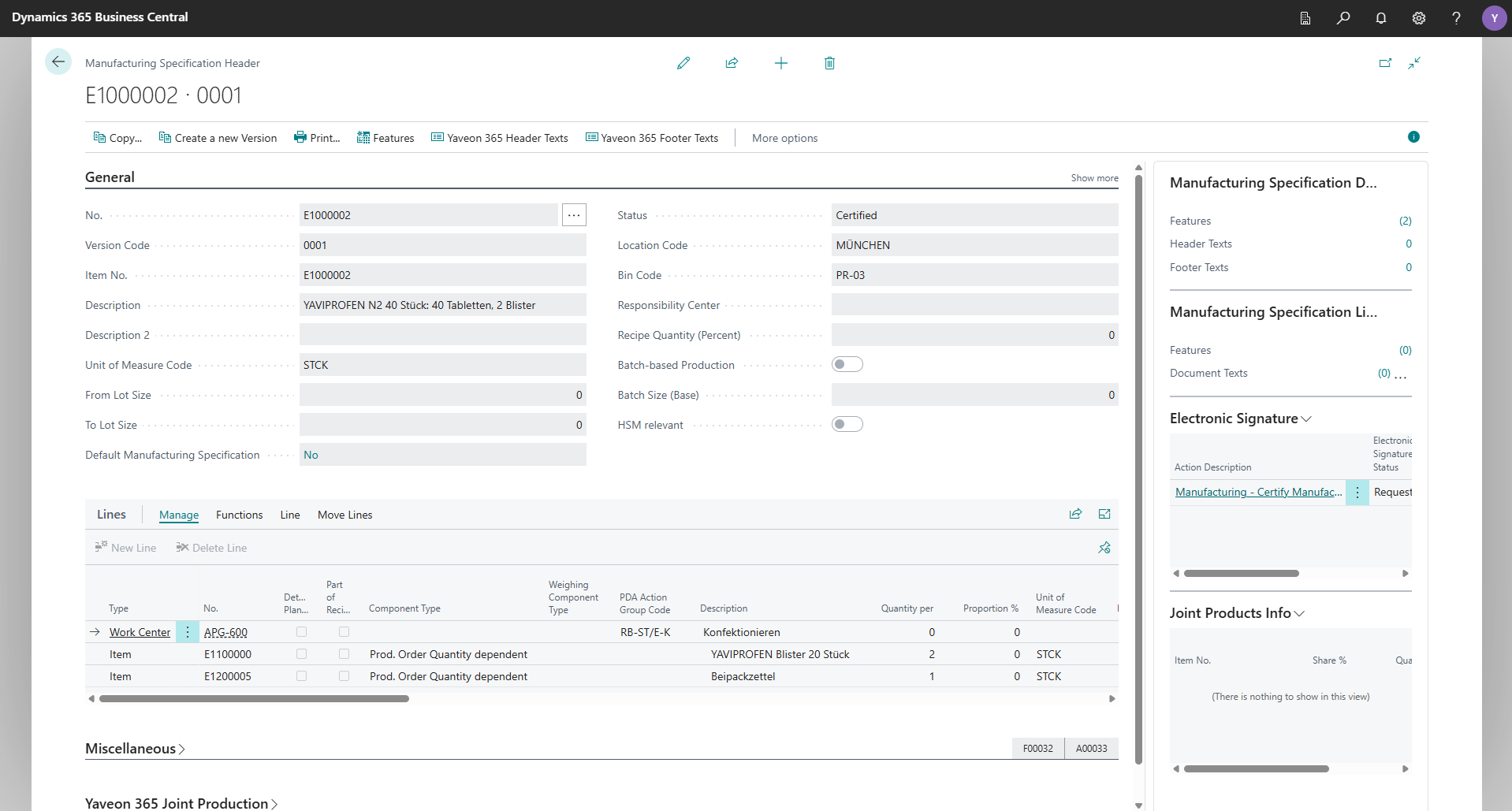

integrated formulation and quality modules

Comprehensive lot tracking

Best-before and shelf-life monitoring

Real-time cold chain monitoring

Recall management at the push of a button

Precise control of fat and protein content

Automatic formulation calculation

Costing of byproducts

Nutritional and declaration information

Hygiene controls in the process

Integration of laboratory and analysis values

Automated audit documentation

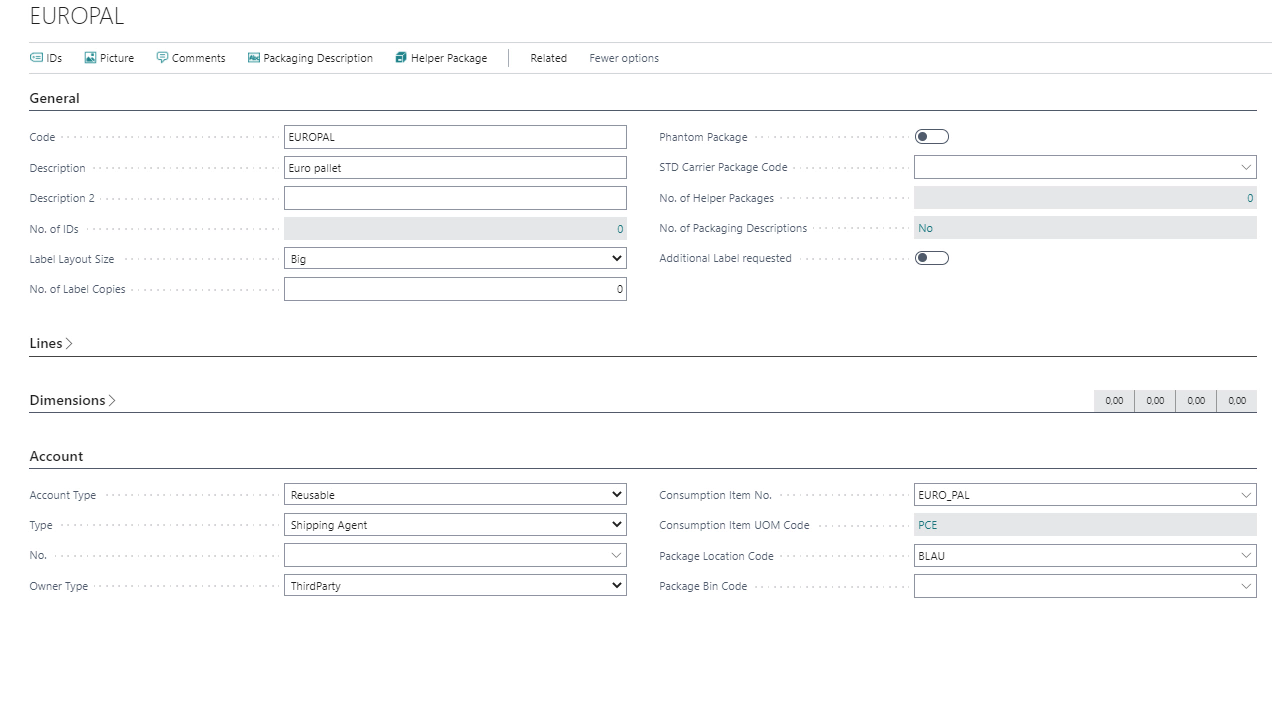

Nutritional value and allergen labeling

Multilingual labels

Export and declaration requirements

Automatic label creation

Optimized route planning

Temperature-controlled transport

Integration with retail & hospitality

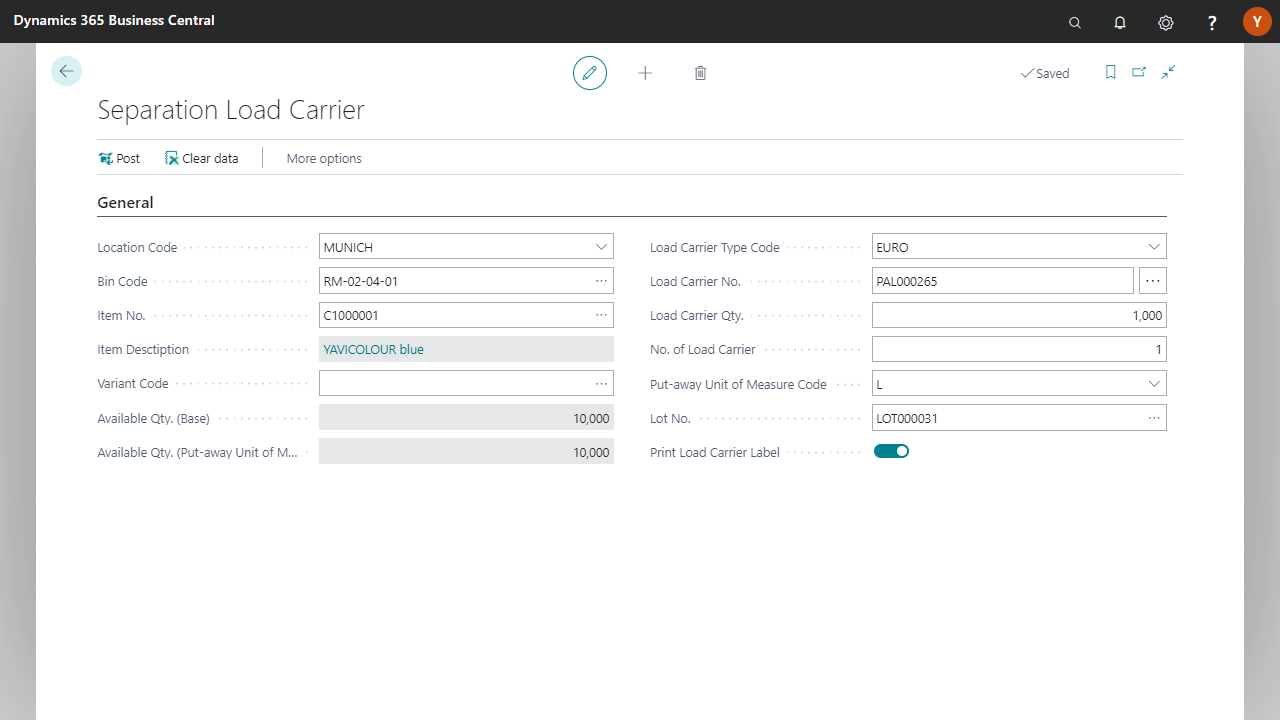

Integration with warehouse management

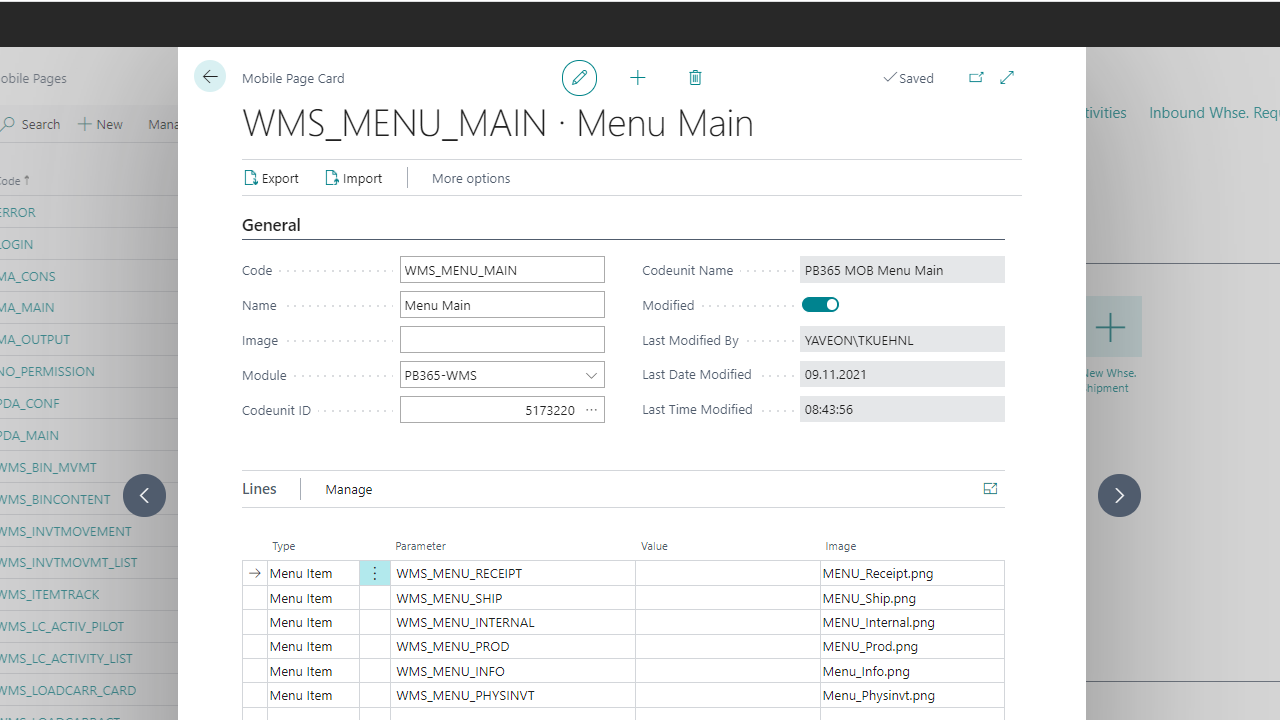

Mobile scanning solutions

Automated inventory postings

Real-time inventory overview

Integration in warehouse receiving and shipping

Yaveon 365 evolves with the specific requirements of dairy processing. It seamlessly integrates acceptance, tank management, lot tracking, ingredient control, and packaging into the Microsoft ecosystem and Business Central, ensuring end-to-end processes from delivery to the finished product.

Yes, the industry-specific ERP solution effortlessly coordinates the parallel production of diverse product lines. Whether it's fresh milk, cheese, yogurt, or milk powder: each line is individually planned and managed, including separate batch and tank management for maximum flexibility and control.

HACCP, BRC, IFS, allergen labeling, and nutritional declaration are already integrated into the system. This ensures that all compliance requirements are automatically incorporated into your production and packaging processes – with no additional effort from your team.

Yes. By accurately analyzing milk ingredients and using intelligent production scheduling, you can maximize your raw material utilization, minimize waste, and increase your margin.

Yes, from tank storage to refrigerated transport and delivery to trade or hospitality, the entire cold chain is monitored and documented.

Yes. From tank storage to refrigerated transport to final delivery to retail or hospitality: Every step is continuously monitored and documented. Route planning and temperature control work seamlessly together.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

Supply chain management food industry – Beitrag öffnen

Supply chain management food industry – Beitrag öffnen

Optimise your food industry supply chain: boost efficiency and margins with the right ERP system.