See how quality control keeps food safe and consistent through testing and regulatory standards.

Full transparency: track batches with recall scenarios

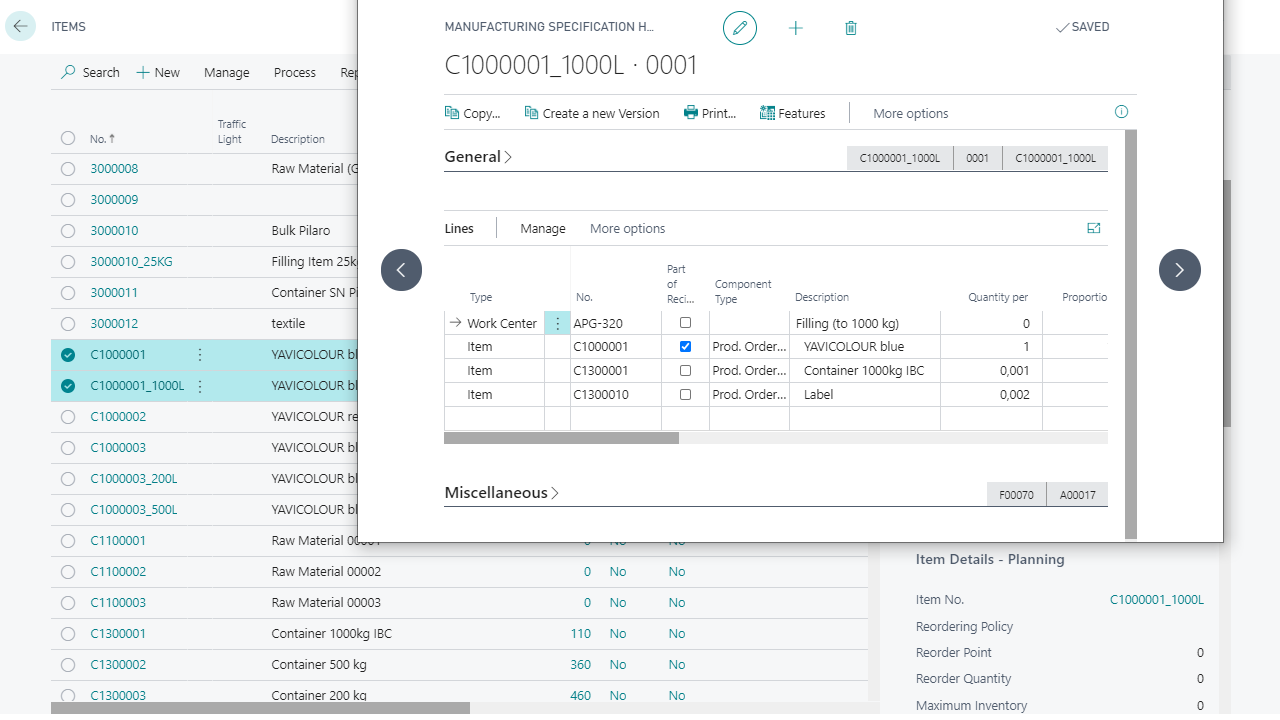

Consistent quality: inspection plans from warehouse receiving to filling

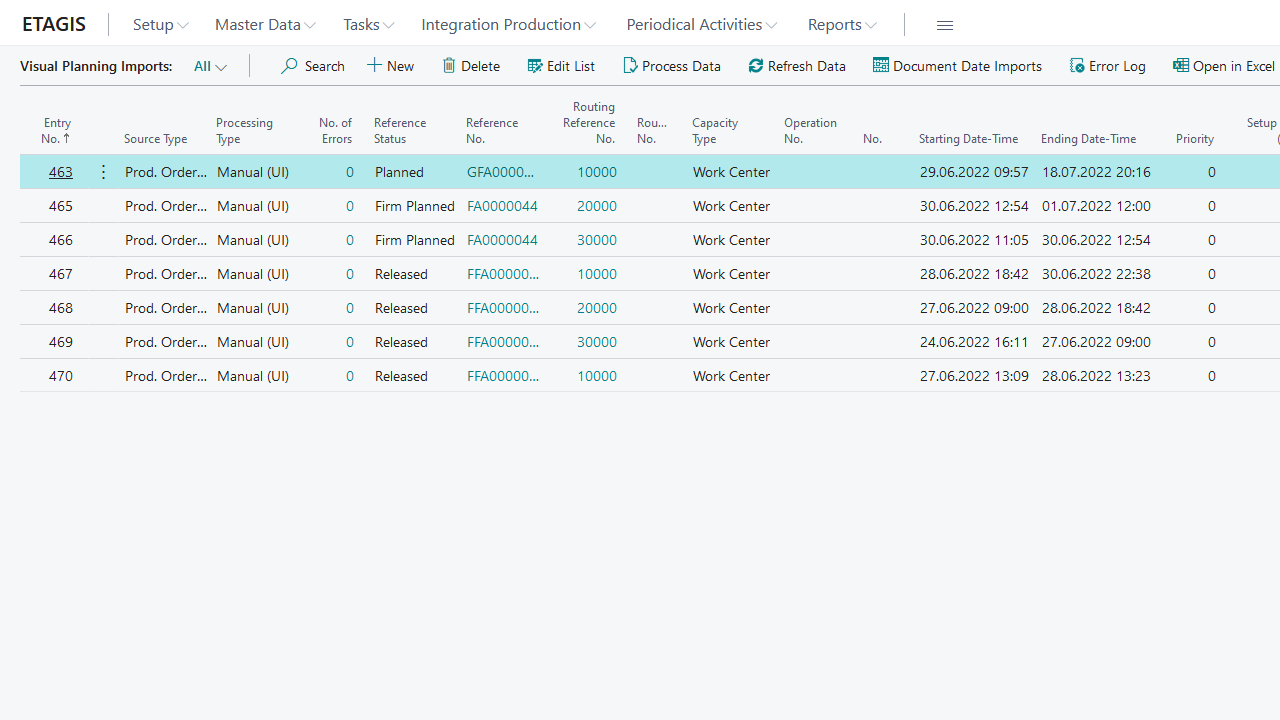

Maximum efficiency: planning & scheduling for kettles and FEFO warehouse

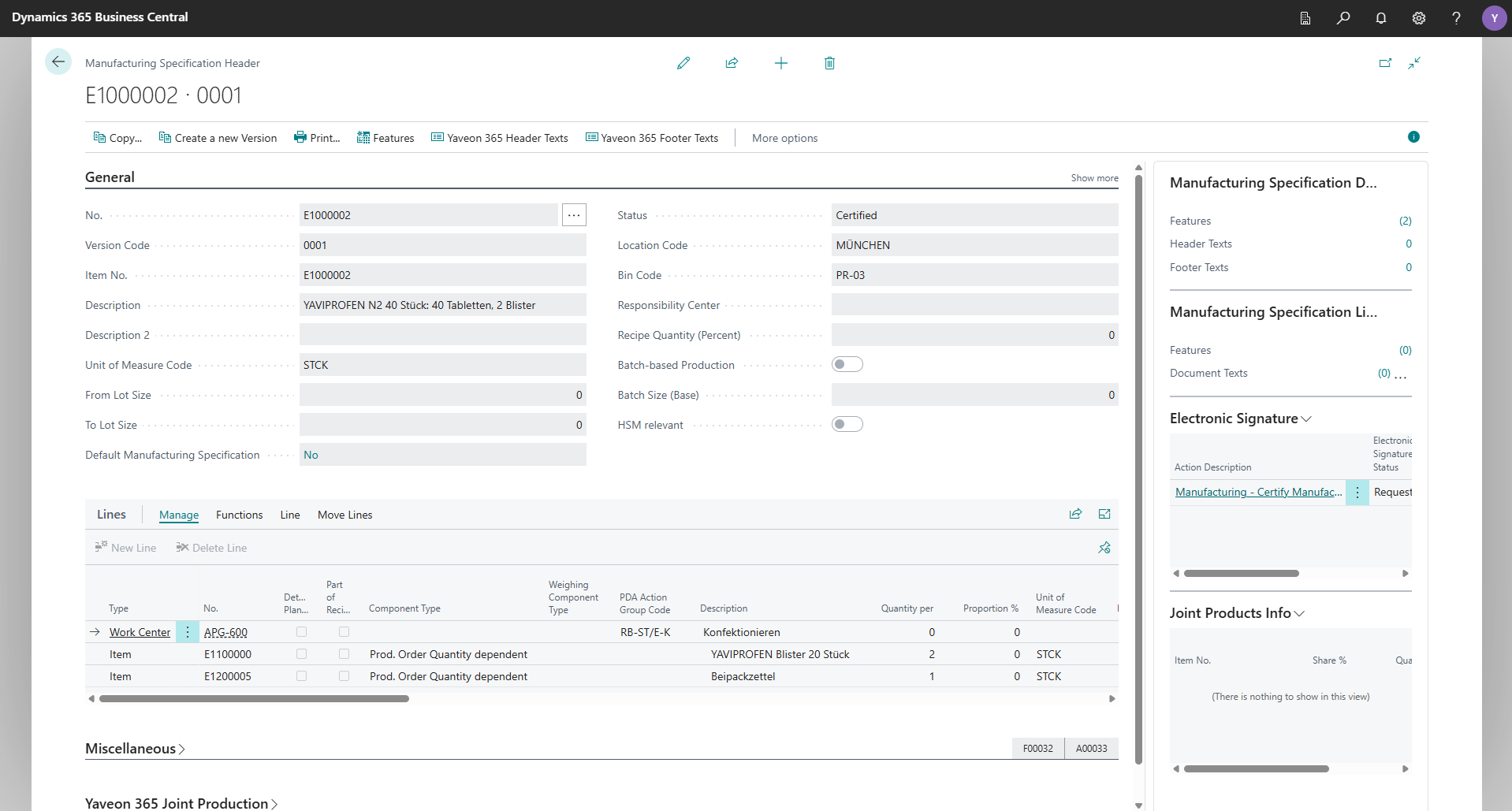

Multi-level formulas with alternatives

Target value control for quality, nutritional values, and costs

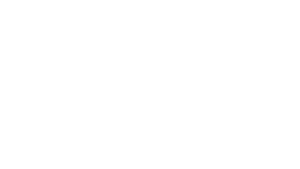

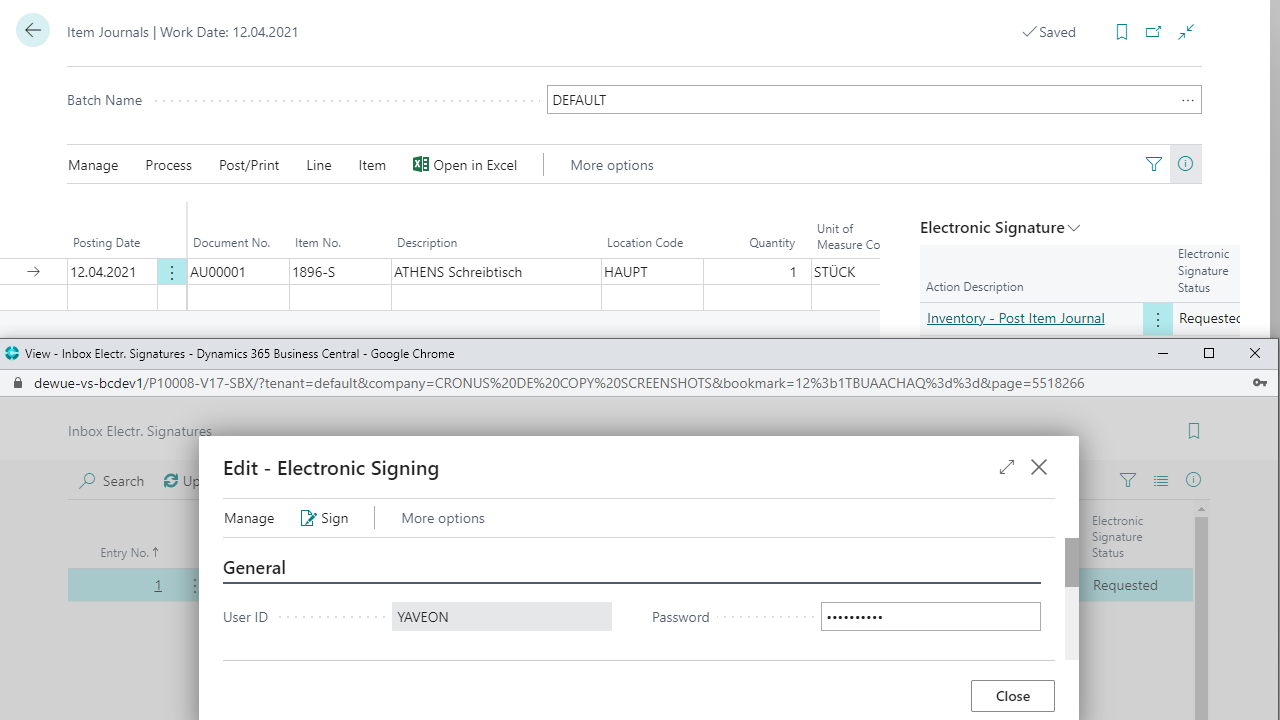

Versioning & approval processes from R&D to quality assurance

Change histories up to label & production

Complex batch processes (kettle → cooling → storage)

Real-time temperature, humidity, and yield tracking

Multiple units (kg, liter, containers)

Post-costing with scrap and rework

Inspection plans for pH, Brix, viscosity, sensory

Block/release status & quarantine processes

Certificate of analysis comparison against specifications

Documentation & test equipment management

1-up/1-down tracking across all processes

FEFO & shelf life logic

Recall reports including affected customers/inventories

Audit trails and event logs

HACCP analyses, CCPs, inspection intervals

Allergen and ingredient lists directly from recipes

Nutrition and ingredient labels according to trade specifications

Multilevel approvals & secure document control

Mobile warehouse processes

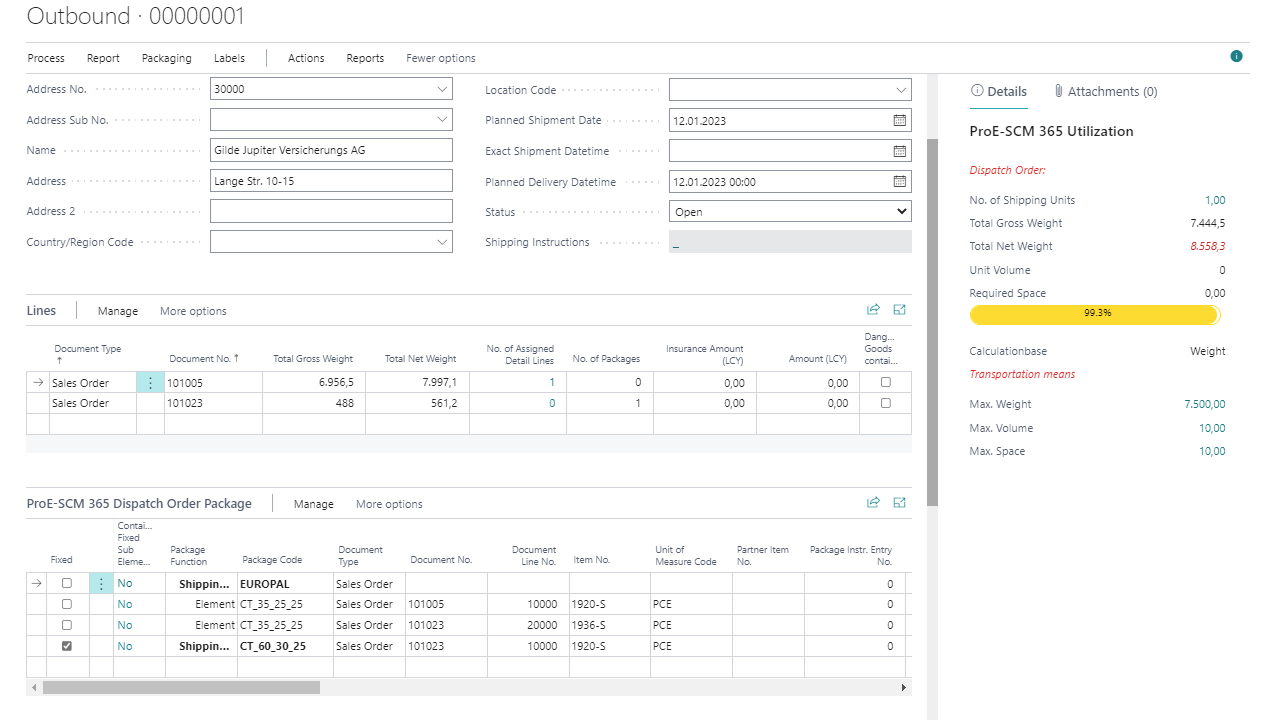

Catch-weight and multiple units in warehouse shipping

SSCC/pallet labels integrable

Inventory valuations including quarantine warehouse

Campaign planning & secondary demand planning

Product allocation by FEFO/BBD

Price tiers & discount logic

Customer/trade contracts with validity periods

Yaveon 365 integrates all process steps from raw materials through batch cooking and emulsion production to filling and shipment. Batches remain completely traceable for organized recall processes, including block and quarantine status.

Formula changes go through defined approval processes with our industry-specific erp before being adopted into production. Target values such as viscosity and pH, along with data relevant to the food information regulation, are automatically, consistently, and version-securely integrated into production control and labeling.

Yaveon 365 records CCP points, cleaning plans, and CIP protocols as mandatory process steps in the system, with documentation completed using an audit trail. CAPA workflows also capture deviations and document these with corrective actions.

Our industry-specific ERP for the sauce and dressing industry includes filling quantities, closures, container shapes, and customer-specific layouts as variants. This ensures that customer and container variants are precisely produced, labeled, and delivered, with bills of materials and work plans automatically adjusting to fit.

Quality assurance test plans in Yaveon 365 define limit values, sampling, and release criteria for emulsion stability and sensory properties. The recorded results directly control batch release and contribute to complaint and root cause analyses.

The industry-specific ERP solution uses rule-based systems to map price and contract logic, as well as promotional periods. Shelf-life specifications and FEFO criteria automatically influence planning, order picking, and delivery, meeting the requirements of both trade and customers.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

Everything about food safety audits – Beitrag öffnen

Everything about food safety audits – Beitrag öffnen

Comprehensive guide to food safety audits that protects consumers and supports GFSI compliance.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.