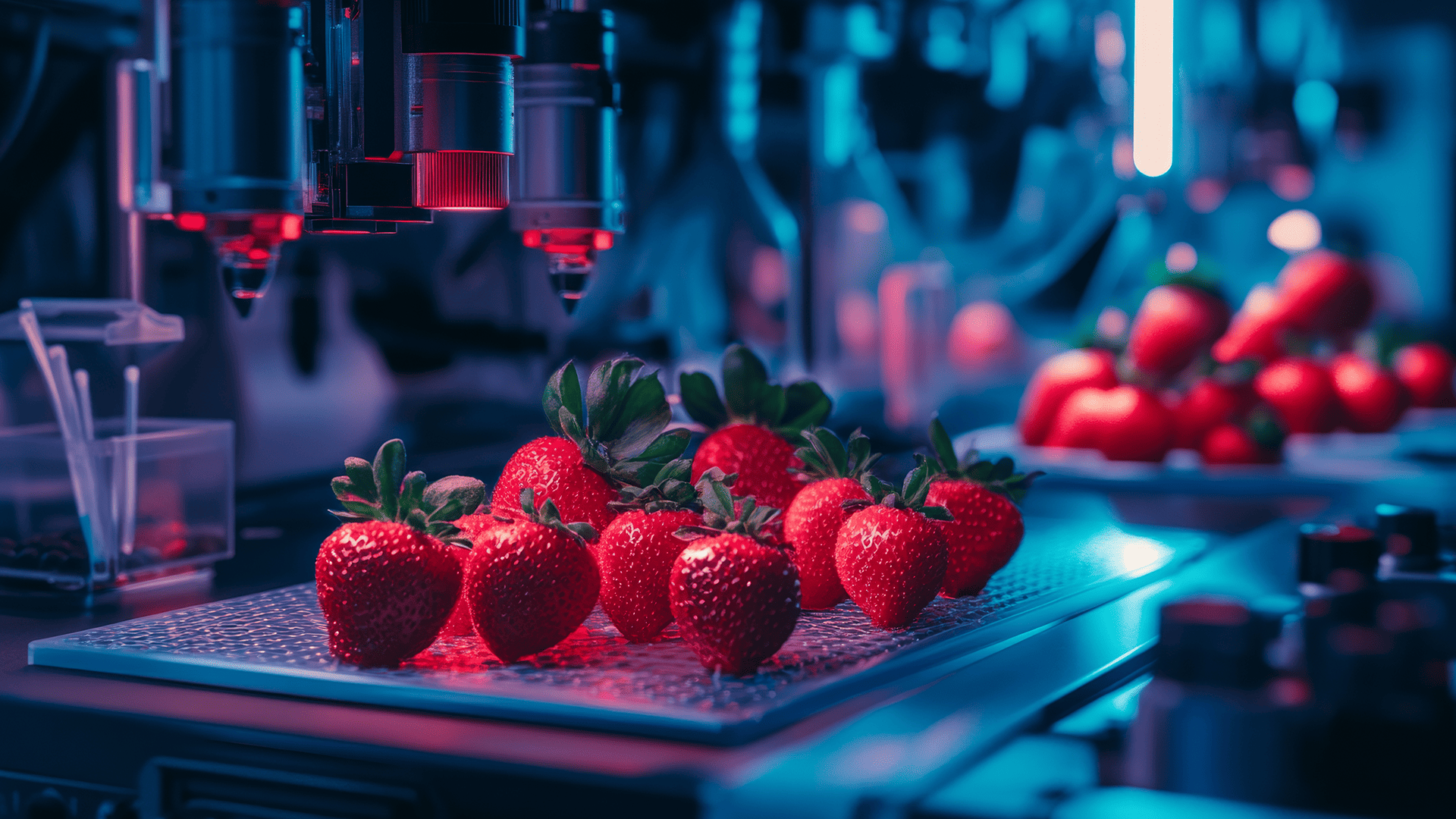

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

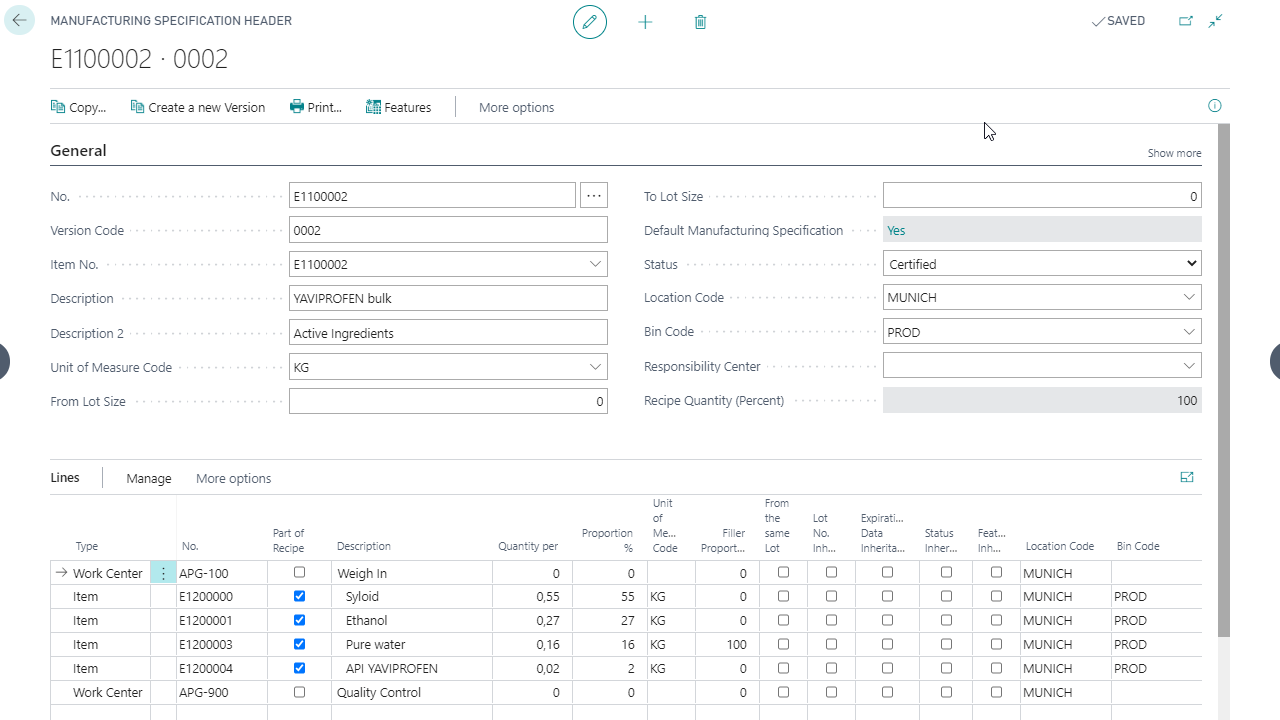

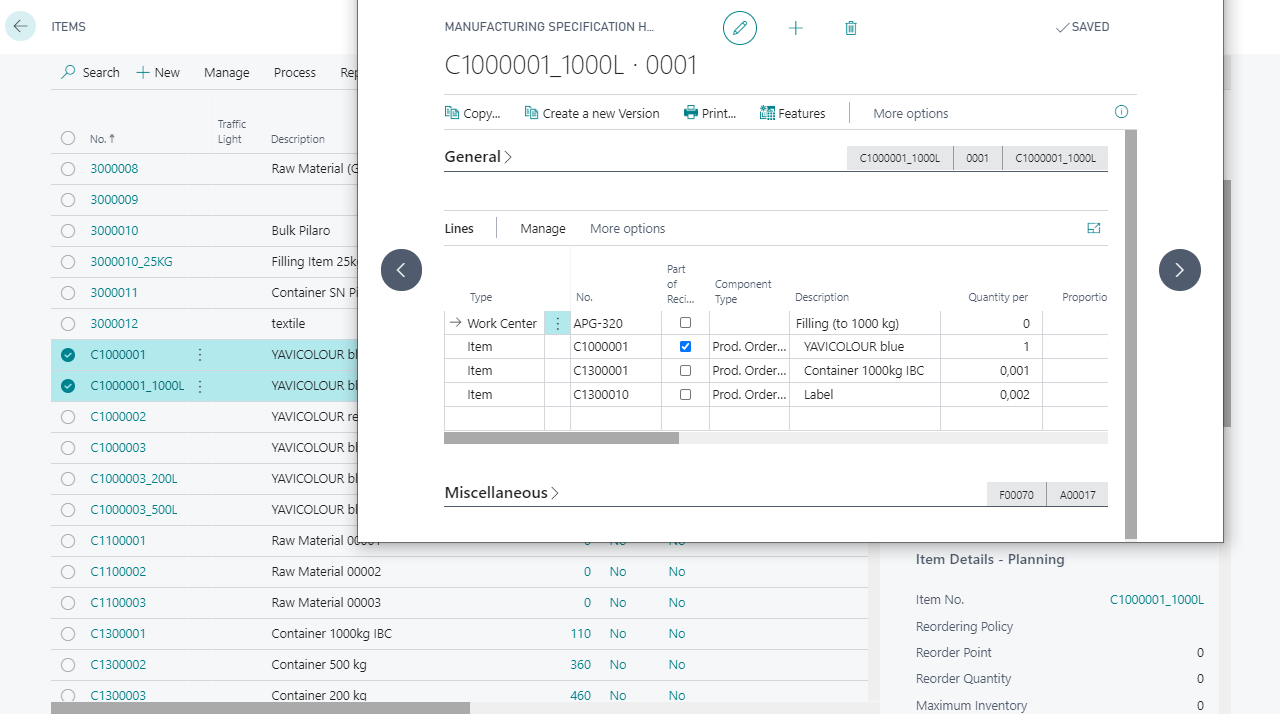

Full transparency: Traceability from raw material receipt to ingredient

Top quality: Allergen management and nutritional declaration

Ensure compliance: Meets the requirements of IFS, BRC, HACCP

Management of ingredients, flavors, and additives

Automatic allergen labeling

Nutritional value calculation per mixture

Flexible customization to meet customer requirements

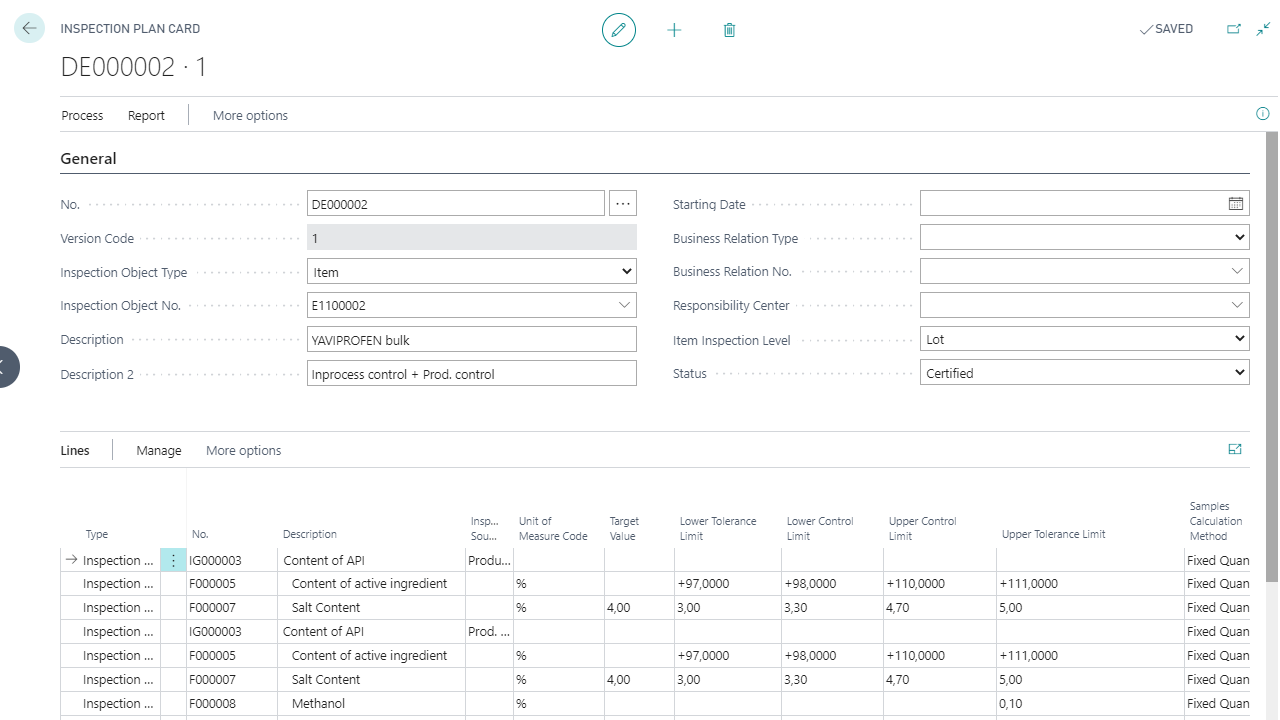

Comprehensive batch control

Expiration and shelf life monitoring

Recall management in seconds

Integrated FIFO/FEFO handling

Purity and moisture checks

Particle size and homogeneity tests

Integrate sensory tests

Automated audit documentation

Planning variable batch sizes

Integration of special and seasonal items

Optimal resource utilization

Precise scheduling

Custom labels

Ingredient, nutritional, and allergen data

Multilingual labels

International regulations integrated

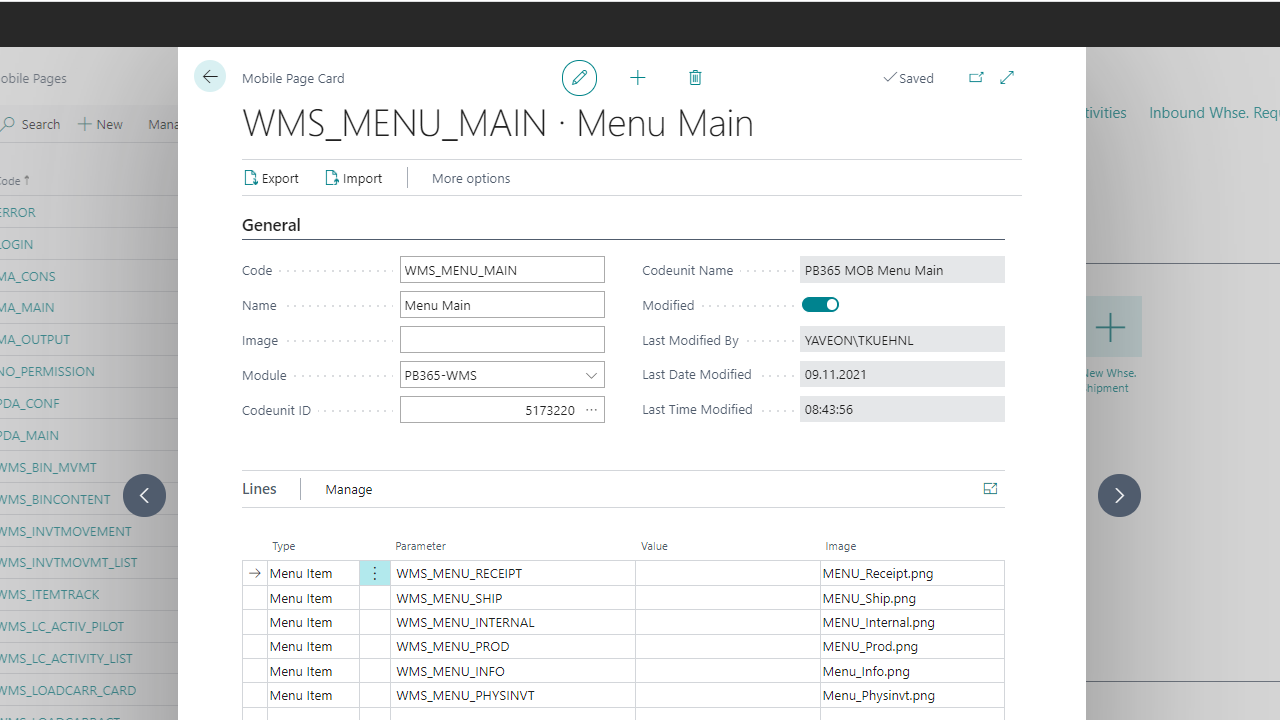

Mobile scanning solutions

Automated inventory postings

FIFO and FEFO handling

Integration from warehouse receiving to shipment

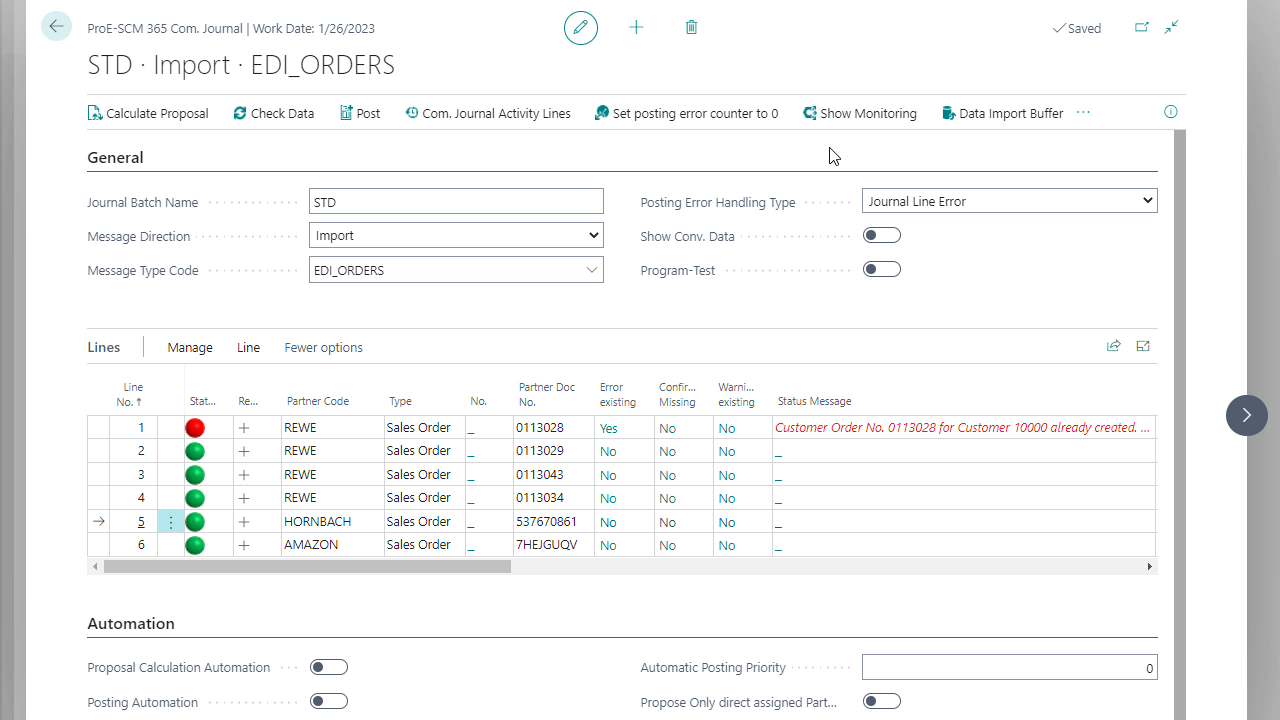

Data reconciliation between shipments and invoices

Transfer of purchase orders, invoices, and payment advice

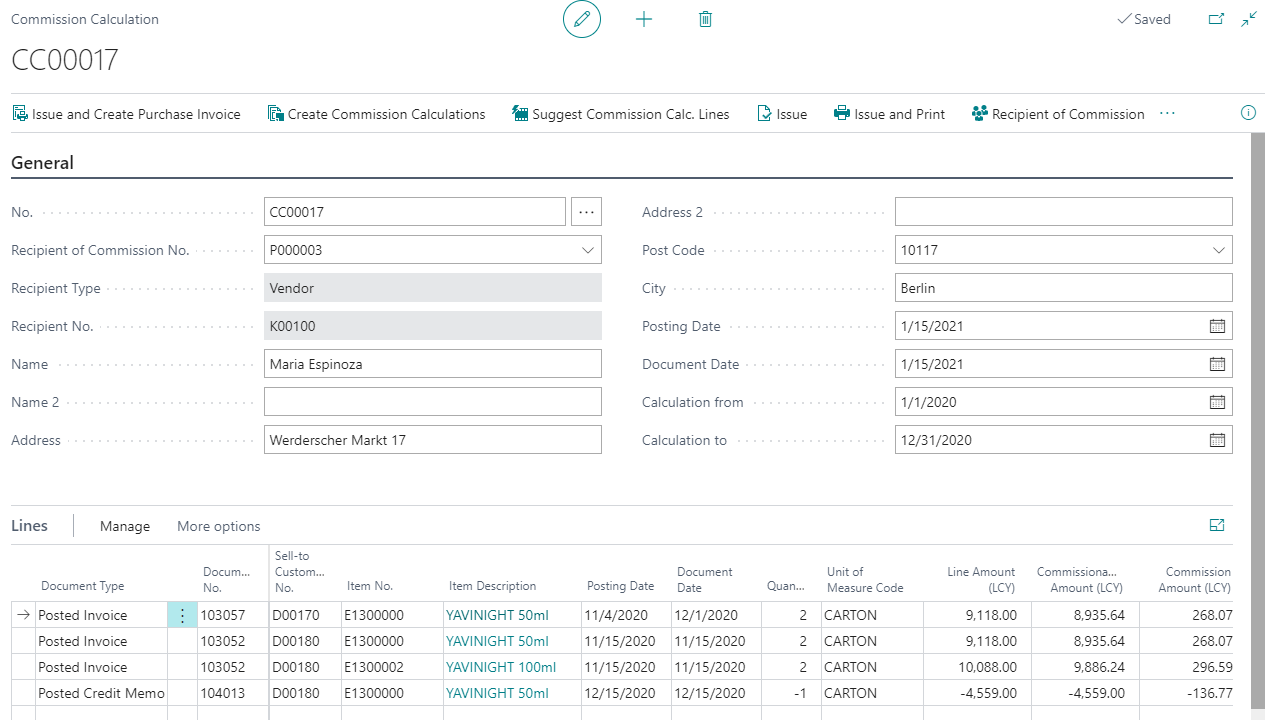

Flexible design of discounts, surcharges, and credits

Import and central management of item catalogs

Flexible control through trade-relevant item groups

Transparent terms with central price overview

Verify listings to prevent incorrect shipments

Multi-level pricing and discount determination

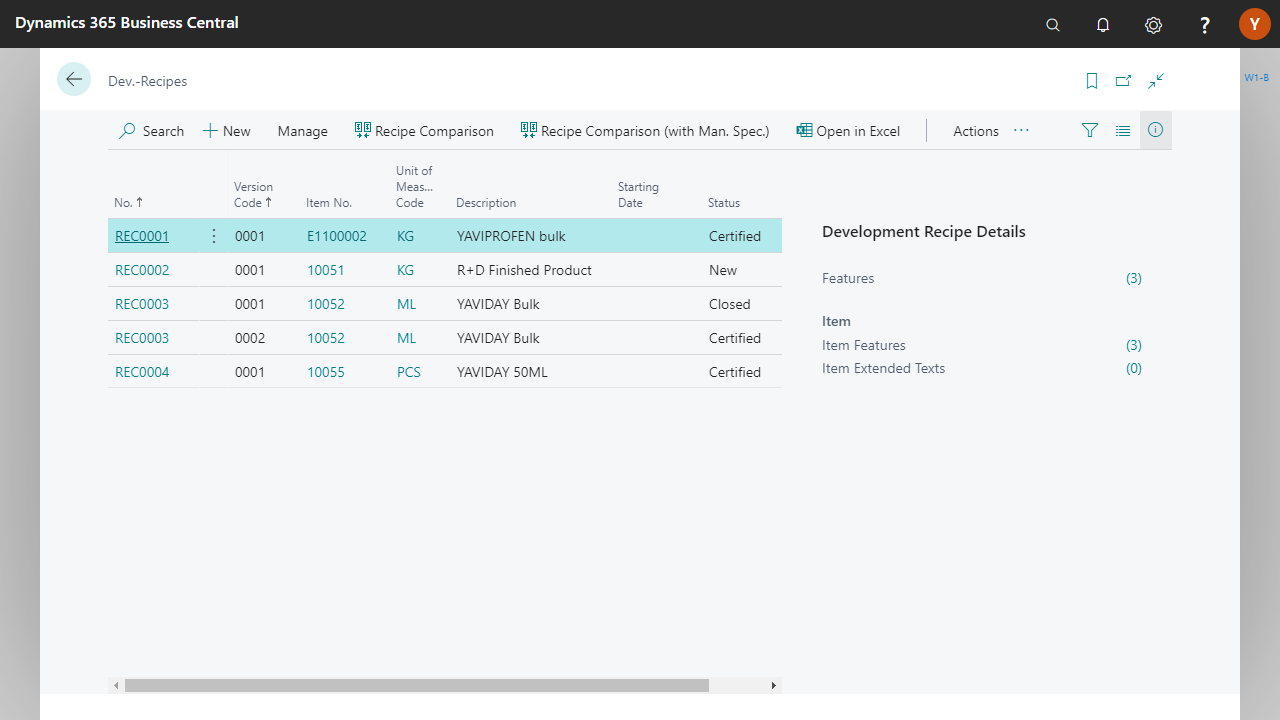

Flexible integration of R&D items into almost all processes

Transition from test to production items

Documentation and management of development recipes

Automatic calculation and management of features

The Yaveon ERP software, Yaveon 365, is the solution for manufacturing and trading companies dealing with food ingredients. It integrates purchasing, production, quality assurance, warehouse, and sales into a centralized system. This allows you to efficiently manage mixing processes, supply chains, and inventories with complete transparency from warehouse receiving to shipment.

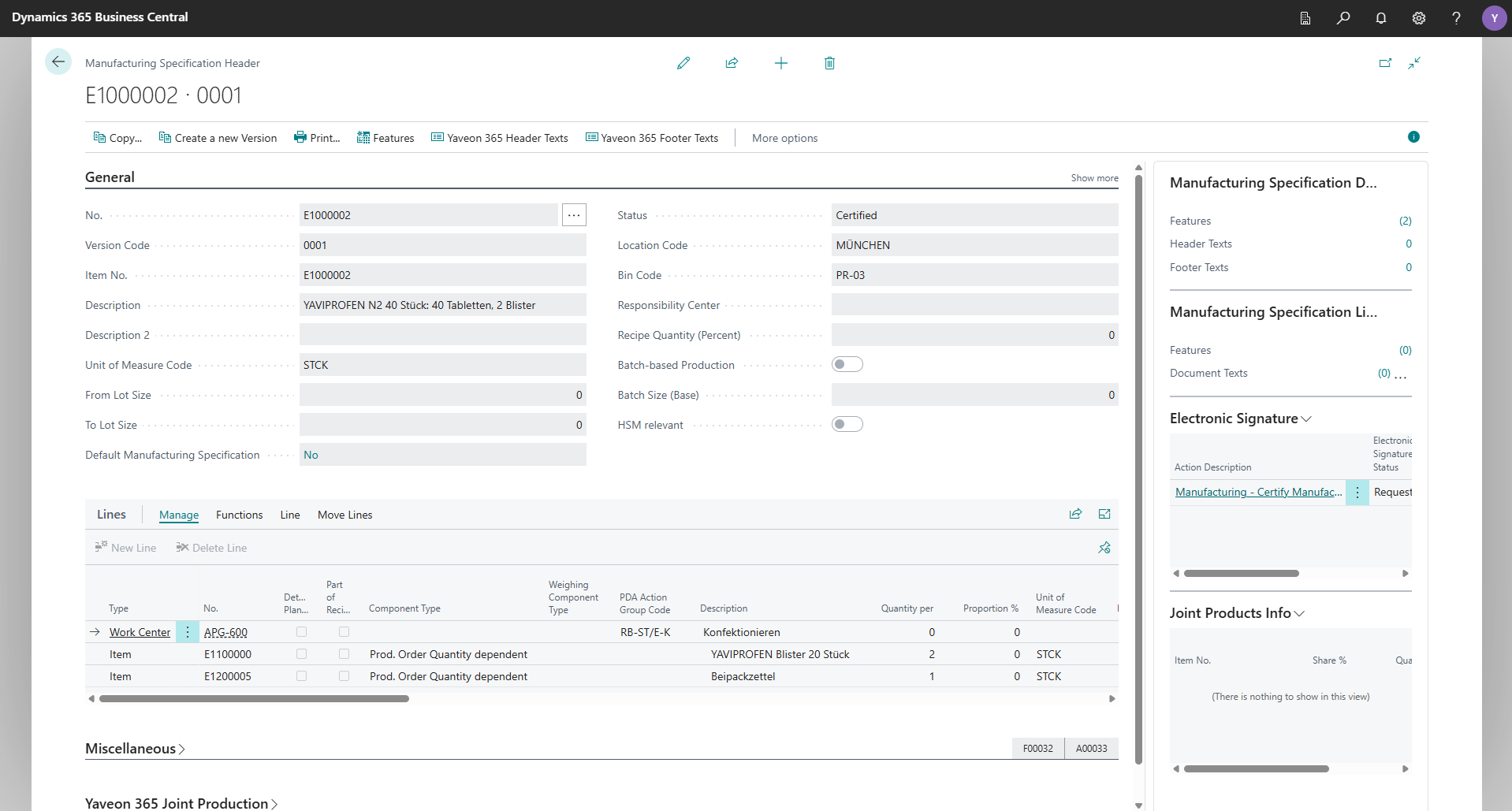

Our ERP solution combines proven ERP features with industry-specific modules: precise formulation and mix management, automated batch and shelf-life management, integrated inspection plans, and flexible packaging and label design. Even complex requirements like allergen or nutritional labeling are seamlessly integrated into the processes.

With Yaveon, you streamline your operations, reduce waste, and ensure consistent product quality — even with frequent recipe adjustments or custom blends. At the same time, you gain real-time insights into inventories, orders, and production status, enabling faster and more informed decisions.

The system seamlessly integrates all relevant regulations — from allergen labeling to international packaging standards — directly into business processes. This ensures that inspections, labels, and supporting documents consistently meet current legal requirements, and all necessary documentation for audits is fully available.

We rely on our proven ProCedures methodology: from detailed requirements analysis to secure data migration and practical team training. The processes are adjusted so that the ERP solution optimally supports your established workflows, not the other way around.

Yes, the solution is based on Microsoft Dynamics 365 Business Central and evolves with your needs. New features, production lines, or locations can be seamlessly integrated at any time without fundamentally altering the existing system.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Supply chain management food industry – Beitrag öffnen

Supply chain management food industry – Beitrag öffnen

Optimise your food industry supply chain: boost efficiency and margins with the right ERP system.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.