Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Complete control: traceability and recalls in the cold chain

Seamless transparency: FEFO/BBD management, catch-weight & more

Top quality: HACCP monitoring & COA inspection

Traceability down to individual batches

Recall simulation with quick batch isolation

Quality hold/quarantine with release workflows

Document storage (specifications, COA) per batch

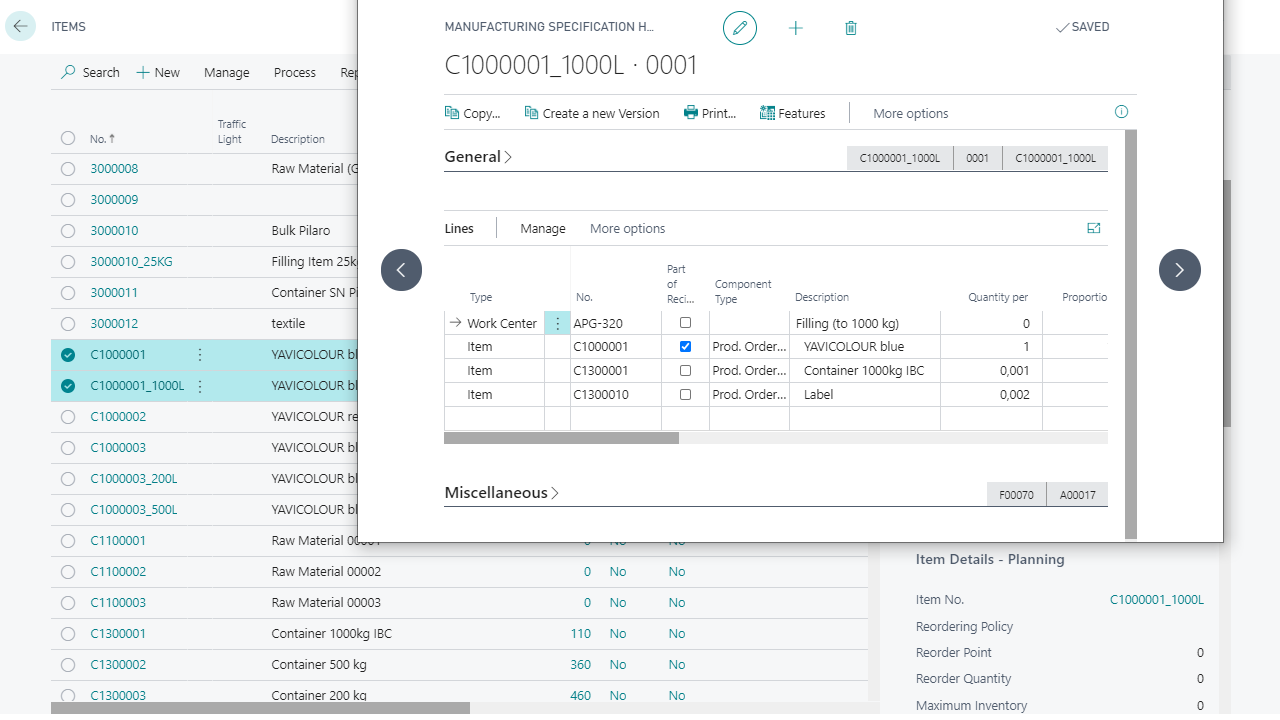

Formula/recipe management including variants and allergens

Batch and item consolidation and capacity control

Yield, waste, and byproduct tracking

Production forecast & mps for line utilization

HACCP checklists & CCP measurements

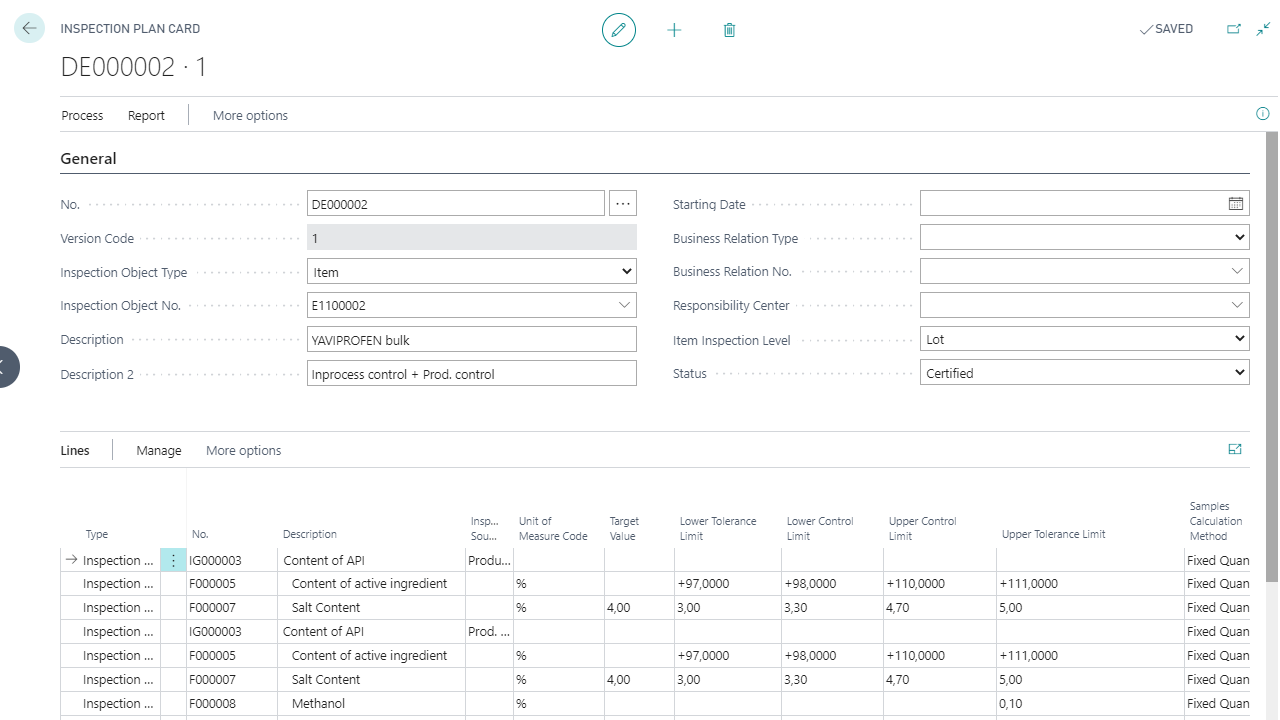

CoA entry & comparison against specification

Quality blocks with block/release and escalation

Preventive maintenance as quality assurance

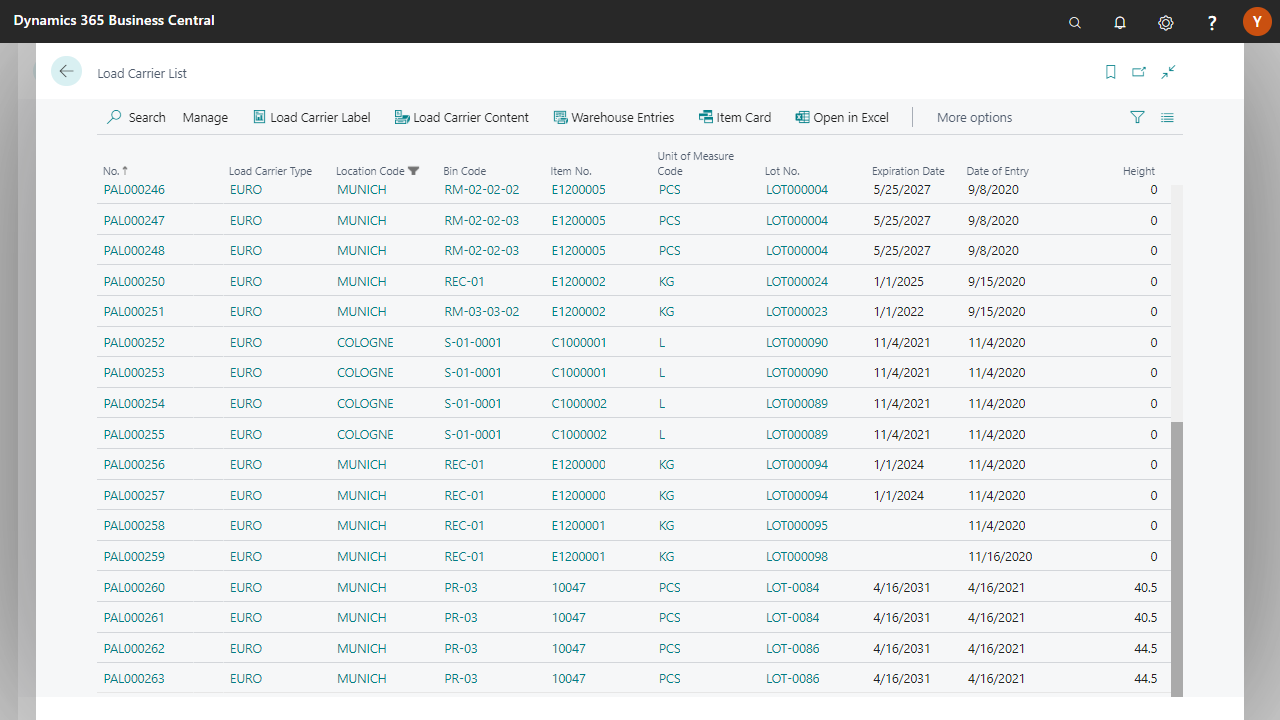

FEFO order picking and minimum remaining shelf life

Mobile scans for warehouse receiving and storage or transfer

License holder/pallet labels and SSCC assignment

Inventory transparency across locations & zones

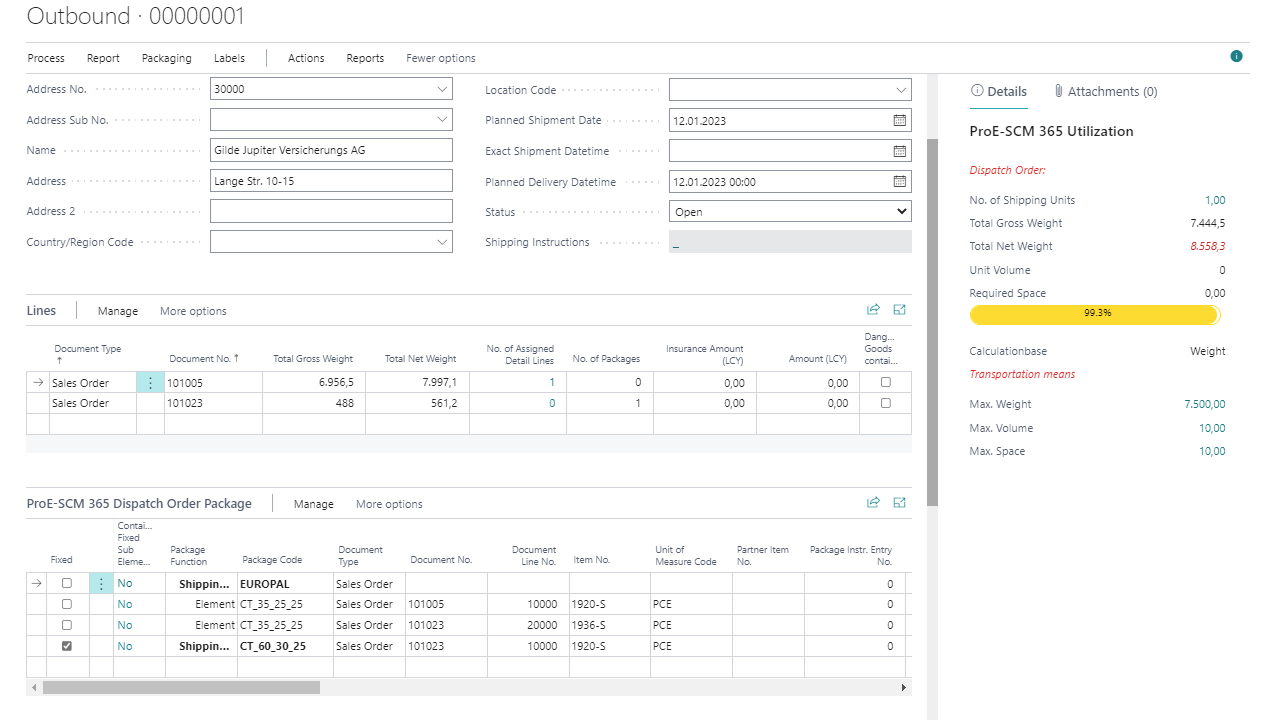

Route and loading space optimization for refer delivery

Integrate 3PL/external cold storage

Document temperature/defrost events

GS1-compliant shipping labels & ASN

Management of raw material specifications and allergen profiles

COA requirement & inspection rules for warehouse receiving

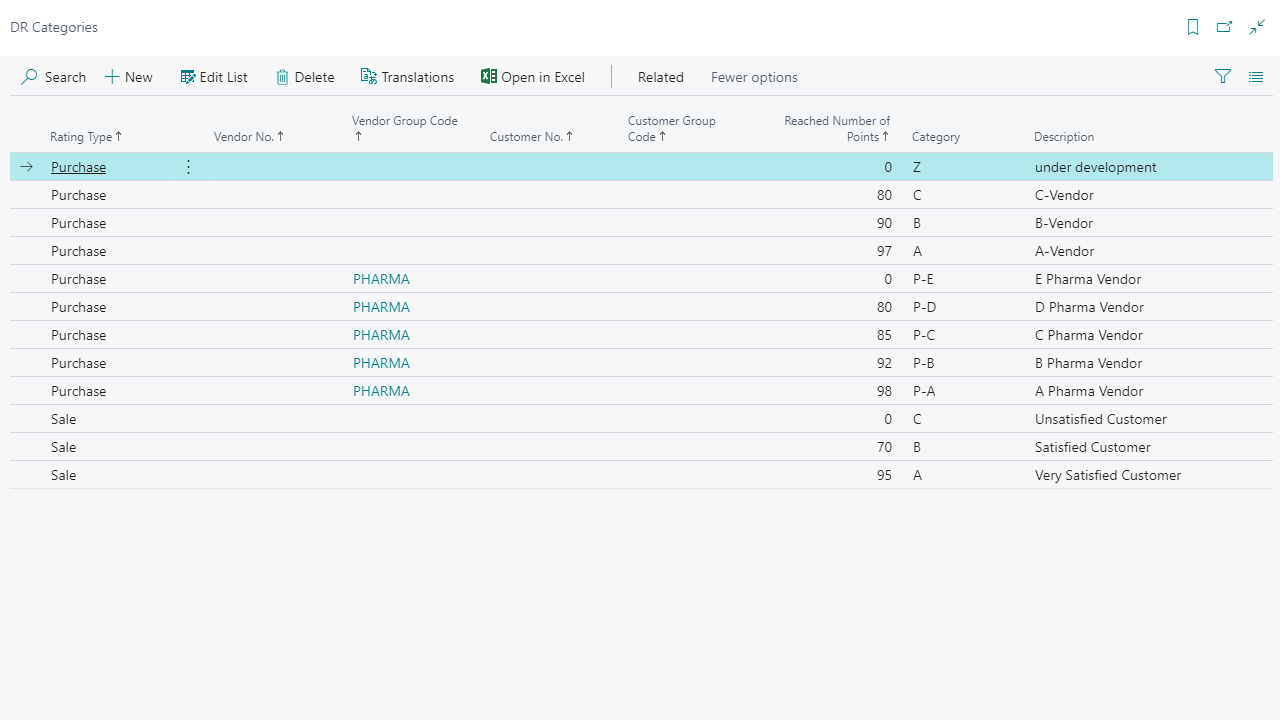

Approval/sanction status for each supplier

Contract positions with quantity windows

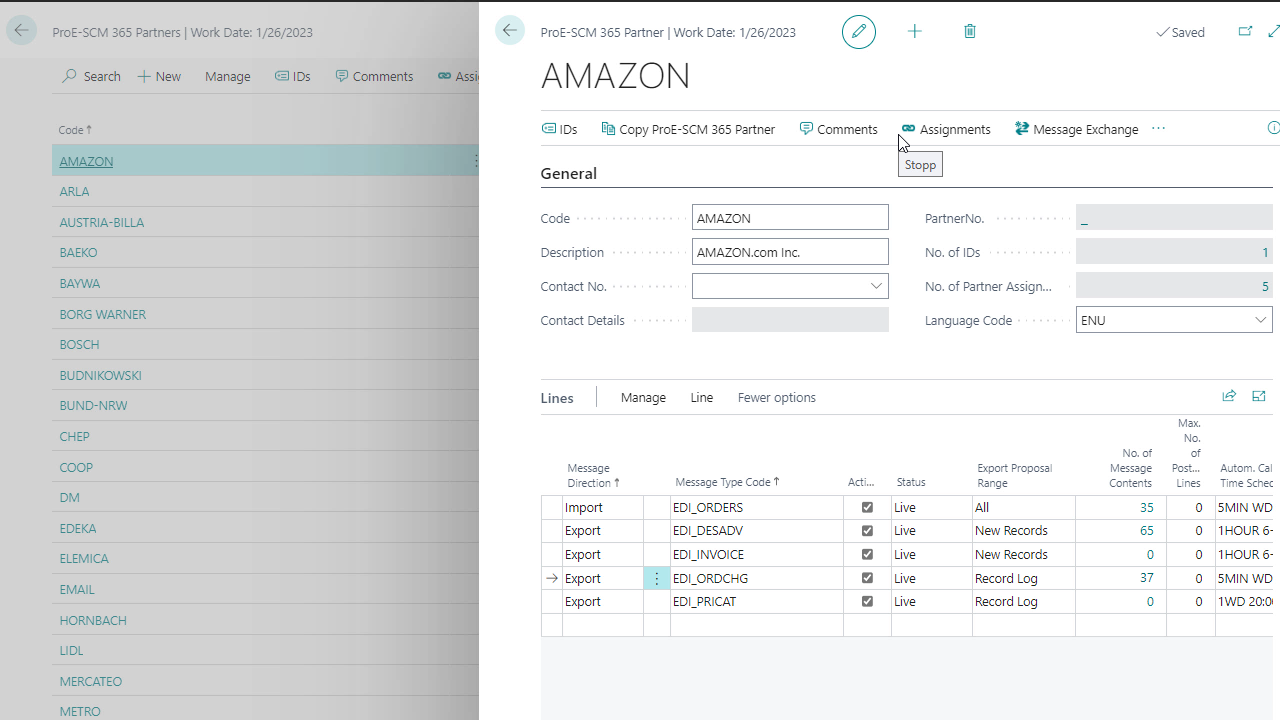

EDI orders, delivery notifications and invoices

Customer-specific sell-by windows and minimum remaining shelf life

Promotional/contract prices, tiered pricing & special customer prices

Catch weight pricing based on actual weight

Yaveon 365 documents all batches across temperature zones and interim storage. Quarantine and release processes are automatically recorded with time and temperature data, enabling quick and comprehensive traceability for recalls.

The integrated detailed scheduling considers batch sizes, setup times, available capacities, and recipe variants. Feedback from production provides real-time data on utilization, efficiency, and deadline reliability.

Formulations are centrally maintained and form the basis for inspection and labeling processes. Customer-specific requirements, such as minimum shelf life or properties, can be directly stored in the system and automatically implemented.

Yaveon 365 automatically records CCP measurements like core temperature or metal inspection, and securely stores hygiene plans and checklists for auditing. Deviations are detected and systematically tracked through CAPA workflows.

Certificates of analysis (COAs) are automatically compared with the specified requirements upon warehouse receiving. Inspection and certificate data determine the release status of each supplier, ensuring the raw material quality is verified.

Yaveon 365 supports standard trading formats—from SSCC and GS1 labeling to customer-specific labels and EDI documents, including ASN. This ensures digital and error-free communication with trading partners, logistics providers, and cold storage logistics.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

Everything about food safety audits – Beitrag öffnen

Everything about food safety audits – Beitrag öffnen

Comprehensive guide to food safety audits that protects consumers and supports GFSI compliance.