Our paper provides 5 tips for the process industry: How to prevent recalls and ensure full batch traceability.

Transparent products: From warehouse receiving to the customer

Efficient processing: Less waste, better planning

Integrated standards: Meets the requirements of IFS, BRC & HACCP

Comprehensive lot tracking

Catch weight management

Best-before date and shelf-life monitoring

Real-time recall management

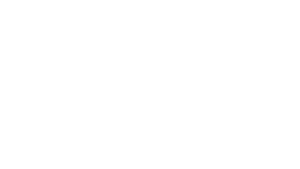

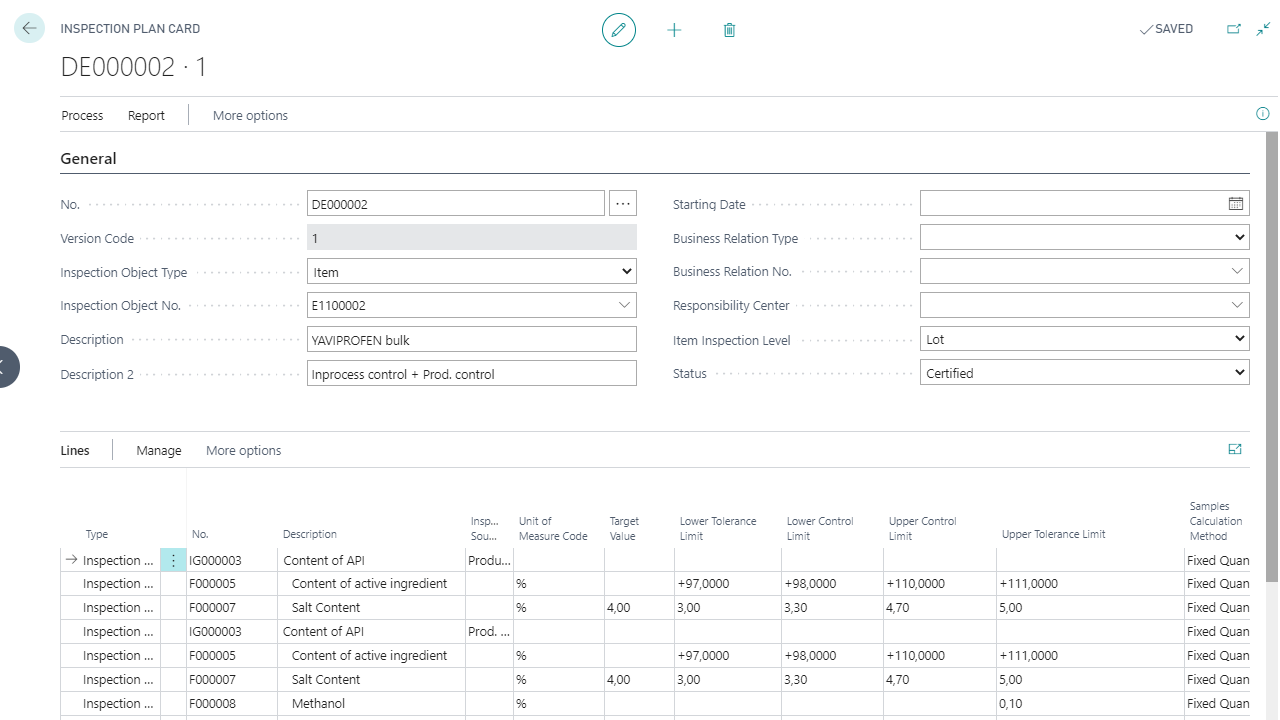

Management of recipes and bills of materials

Integrated allergen management

Nutrition calculation for export & trade

Flexible variant planning

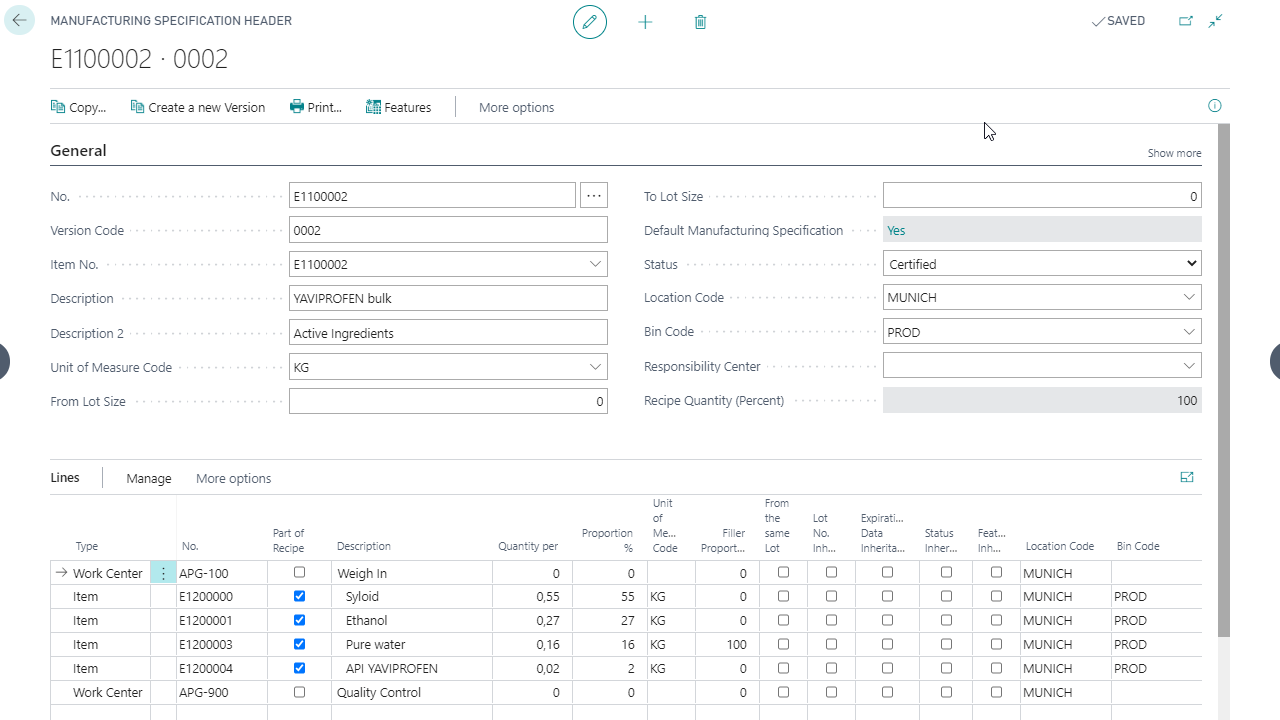

Hygiene inspections and documentation

Sensory tests during the process

Automated audit documentation

Direct link with batch and production data

Planning of batch sizes and variants

Multi-product and byproduct processing

Real-time capacity control

Resource optimization

Customer and export-compliant labels

Multilingual labeling

Automated nutritional information

Integration of international standards

Tour and Route Planning

Real-time cold chain monitoring

Supply for trade, gastronomy, and large customers

Integration with ERP and warehouse systems

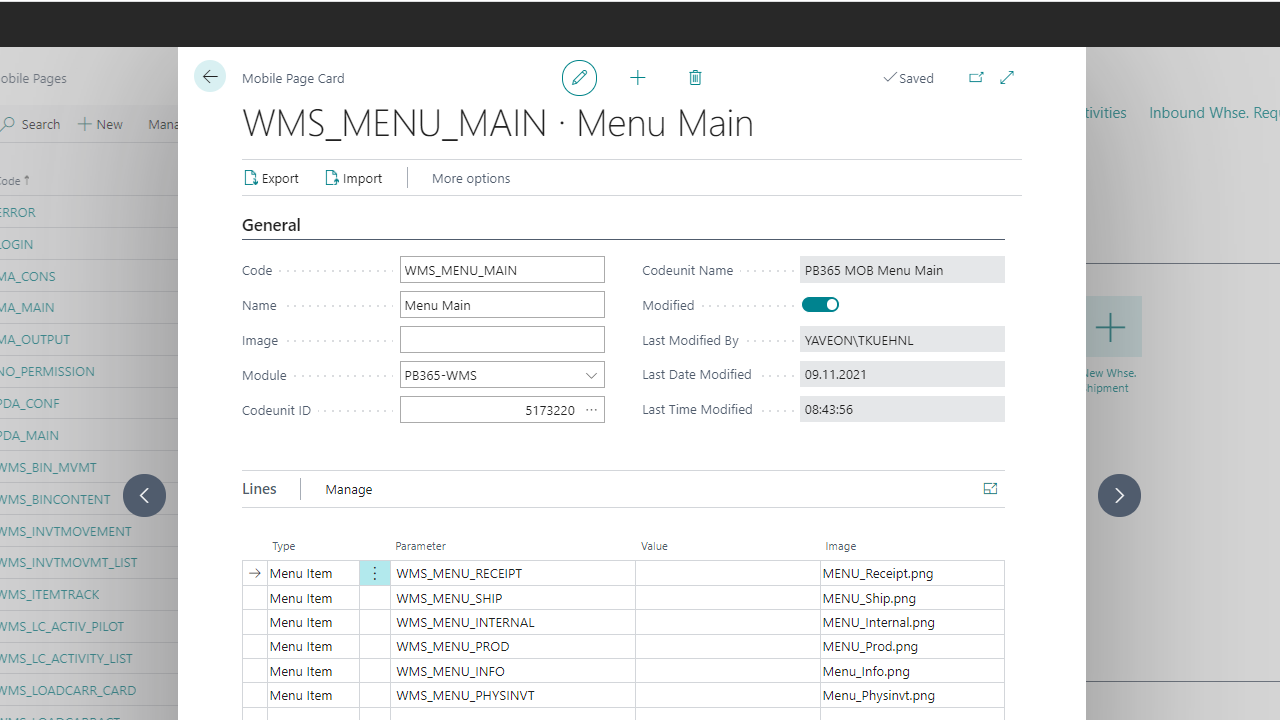

Mobile scanning solutions

Error-free inventory postings

Quick transfers

Integration in warehouse receiving and shipping

Our industry-specific ERP software, Yaveon 365, is tailored to meet the needs of meat processors. It optimizes all core processes – from purchasing and processing to packaging and distribution – ensuring maximum efficiency, comprehensive traceability, and adherence to the strictest hygiene and quality standards.

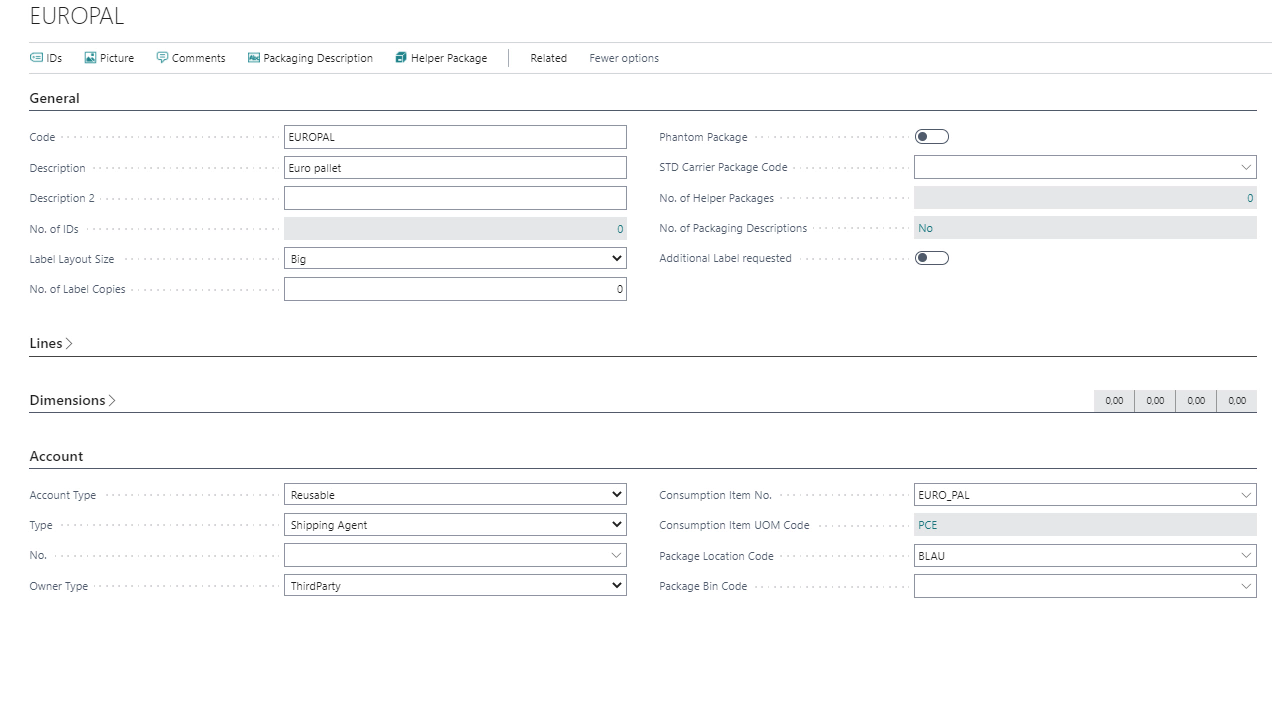

The solution addresses all industry-specific requirements: catch weight handling (variable weights), batch and shelf life management, yield and performance control, integrated hygiene inspections, formulation and bill of materials management, packaging and labeling solutions, as well as cold chain and route planning.

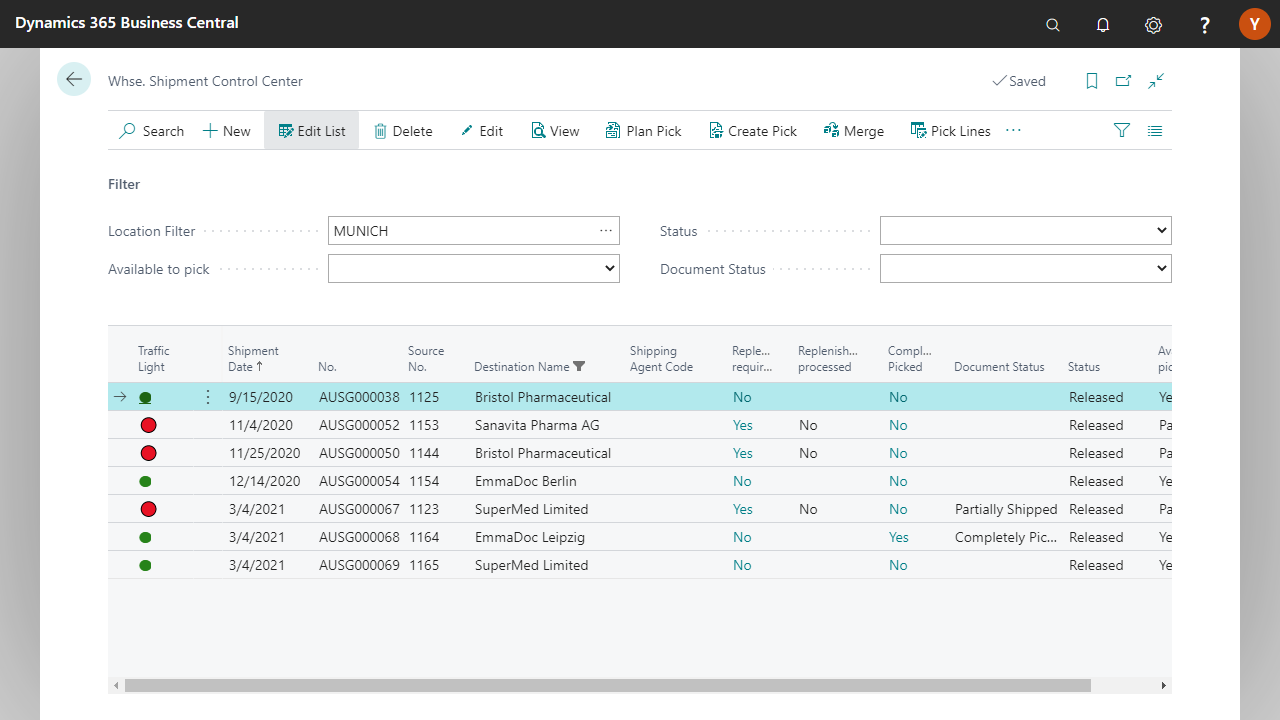

With real-time tracking, automatic documentation, and auditable quality controls, you can transparently trace every batch from warehouse receiving to the customer. Quickly identify deviations, manage recalls efficiently, and comply with legal standards such as IFS, BRC, or HACCP.

You reduce waste, ensure freshness and quality, optimize utilization, and increase efficiency at every process stage. Simultaneously, you enhance planning capabilities, automatically meet compliance requirements, and establish a scalable IT foundation that grows with your business.

We rely on our proven ProCedures methodology, secure data migration from existing systems, customized adjustments to your processes, and practical training to ensure your team effectively uses the system from the start.

Yes. Yaveon 365 is specifically designed for meat products and efficiently manages variable weights (catch weight), joint production, and mixed recipes without affecting traceability or costing.

5 tips how you can avoid recalls – Beitrag öffnen

5 tips how you can avoid recalls – Beitrag öffnen

Our paper provides 5 tips for the process industry: How to prevent recalls and ensure full batch traceability.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Supply chain management food industry – Beitrag öffnen

Supply chain management food industry – Beitrag öffnen

Optimise your food industry supply chain: boost efficiency and margins with the right ERP system.