Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Industry-specific ERP: specifically for pet food & feed

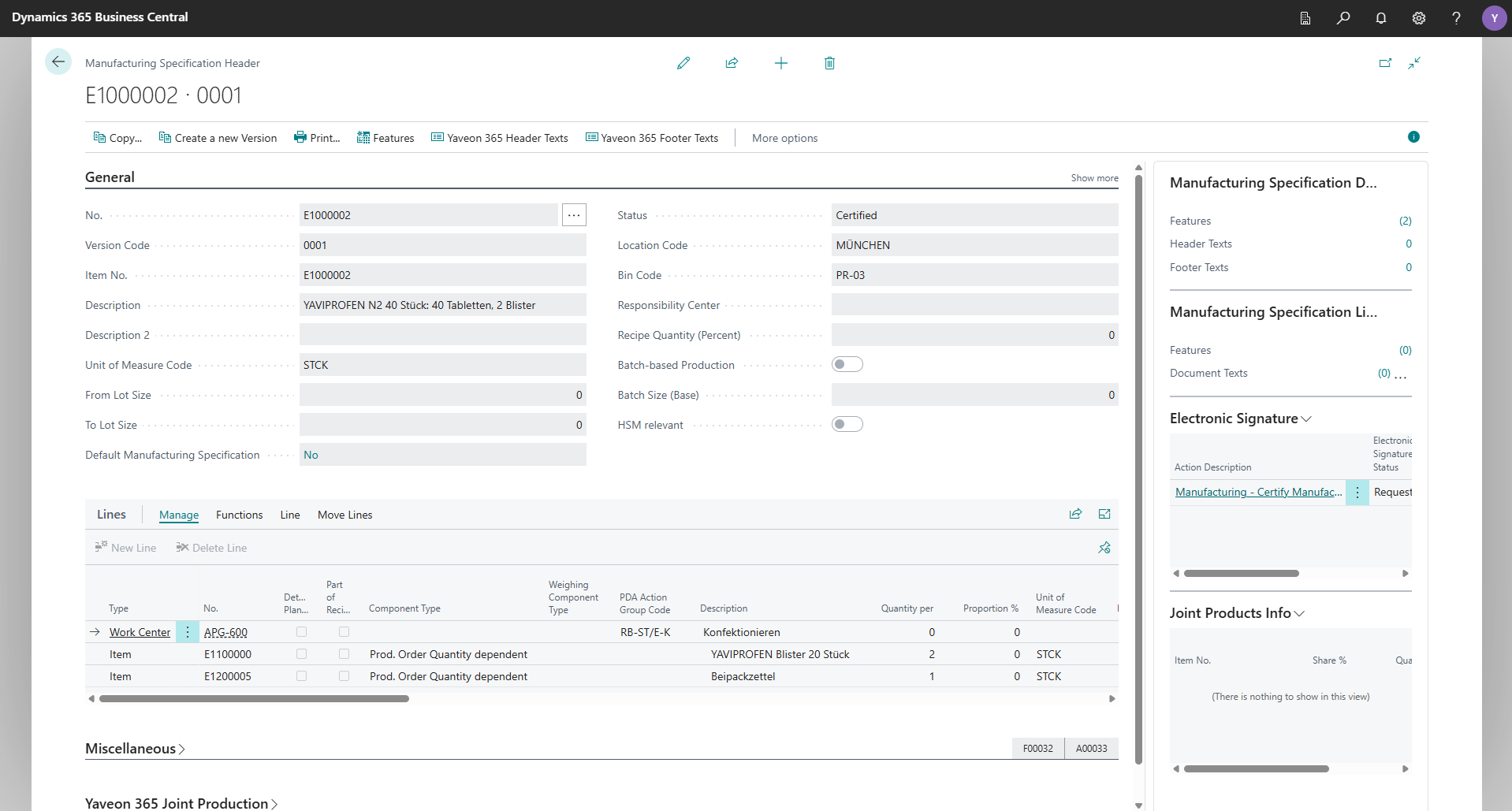

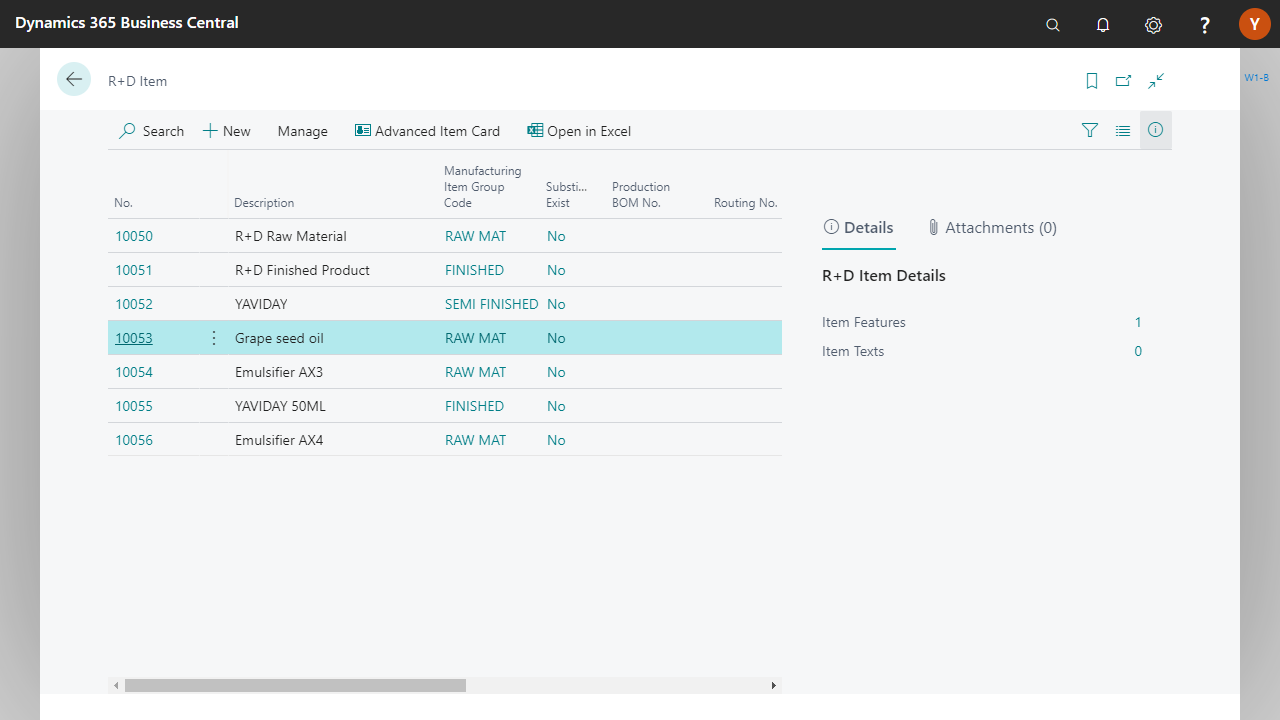

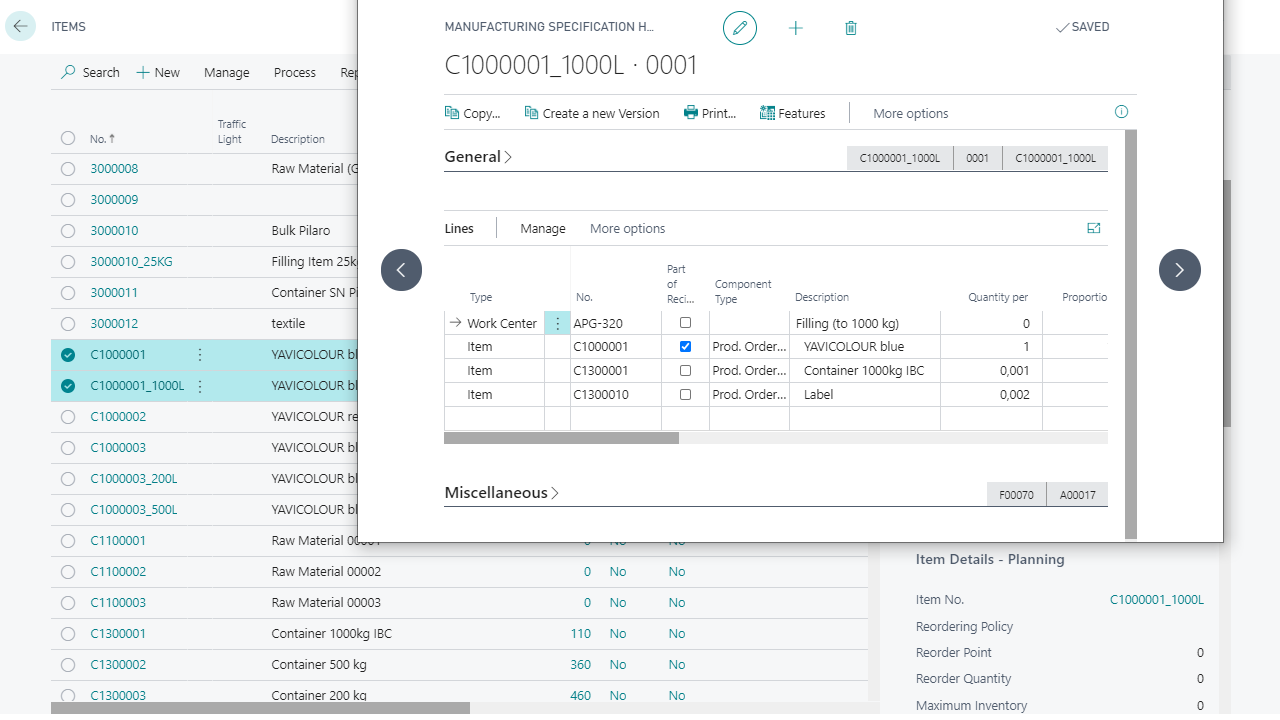

Recipe management & versions

Preliminary/final costing

Nutritional value & allergen management

Claims & declaration rules

Batch & lot management

Best before date and recall management

CAPA workflows

Feed traceability

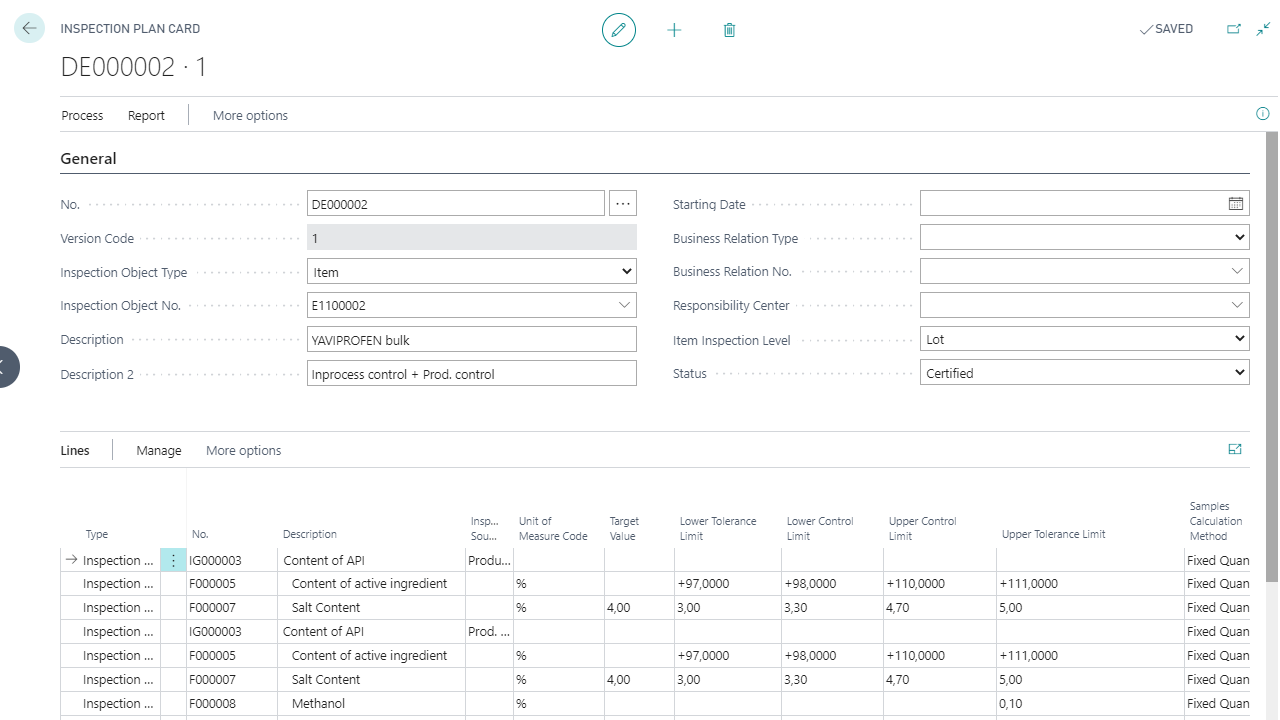

Inspection plans & COA comparison

Supplier approvals and evaluation

Blocking/release status

Deviation/audit documentation

Nutrition and allergen labeling

Best-before date/lot details

Multilingual labels

Variable packaging units

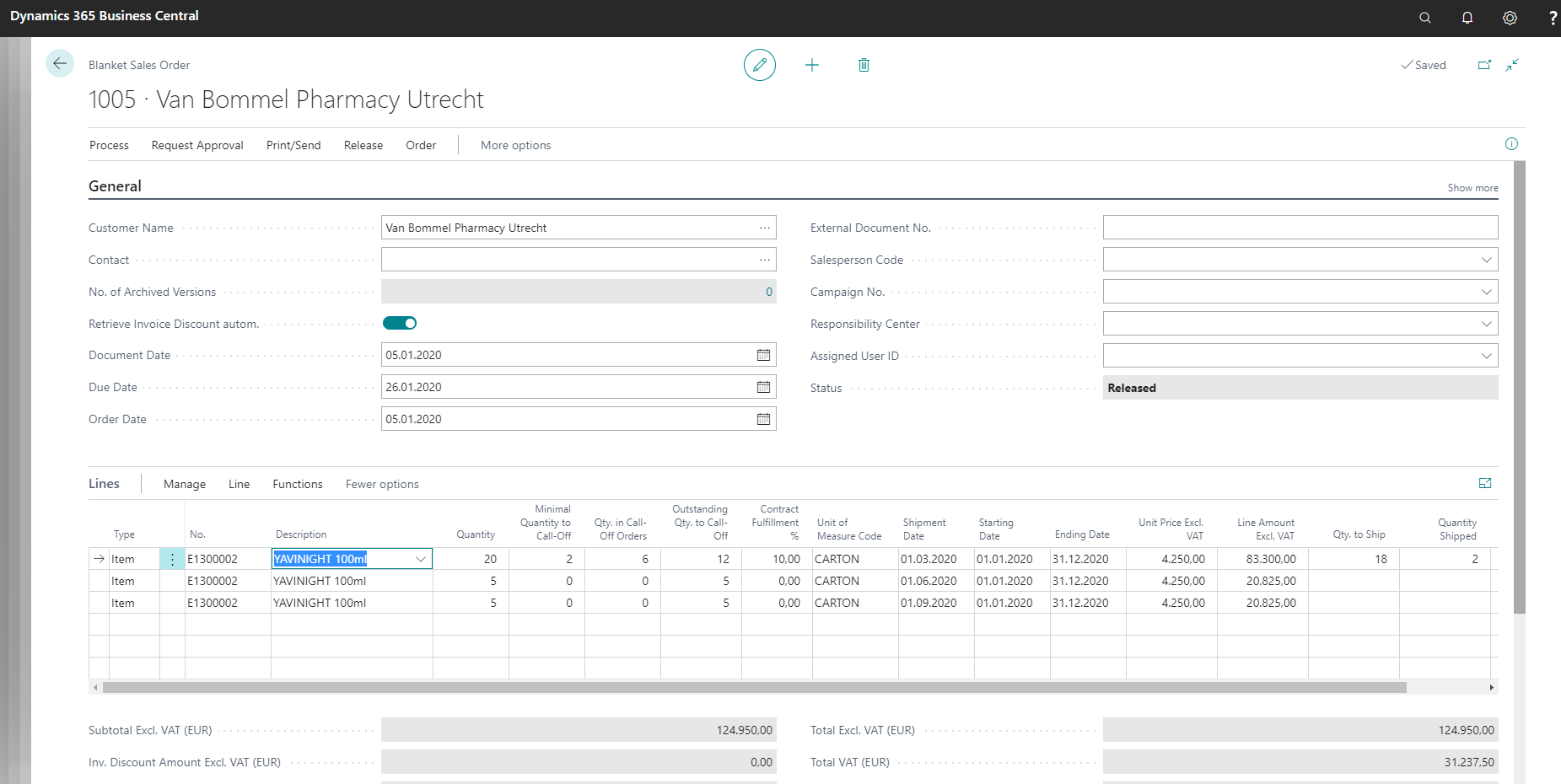

Price & contract management

Currency Management

Supplier evaluation

Raw material price and risk hedging (optional)

Inventory & Lot Management

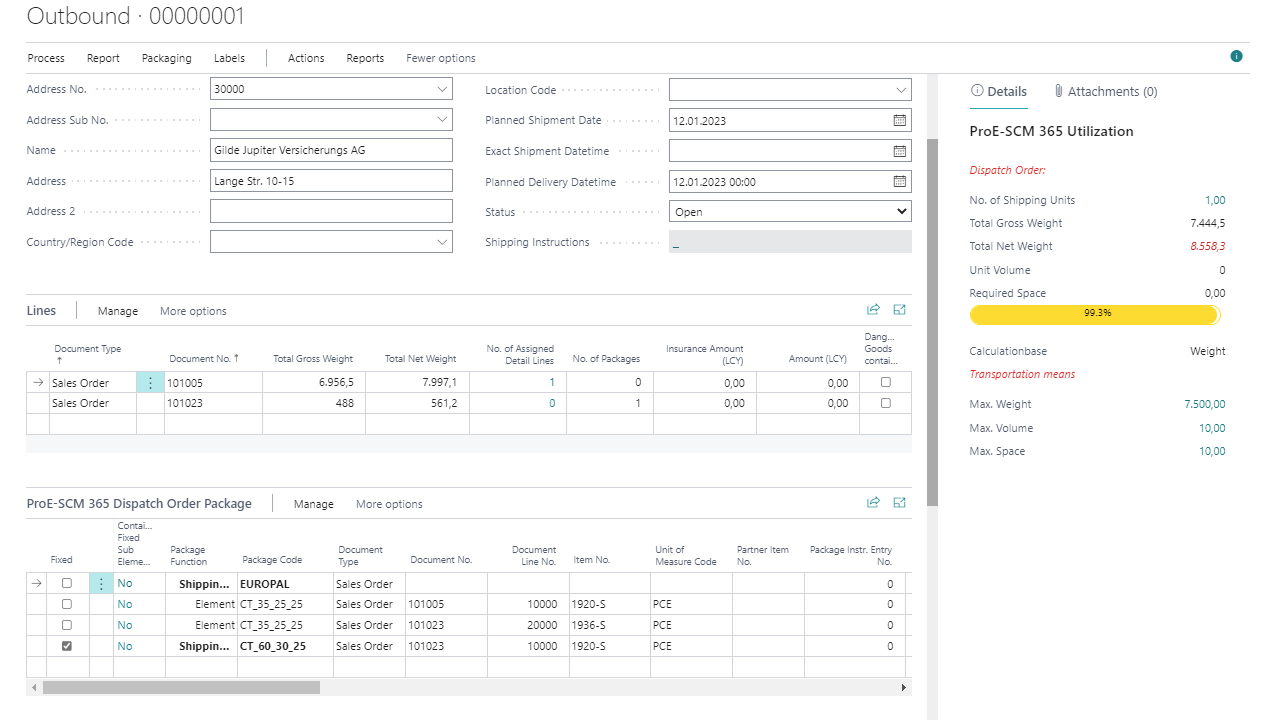

Scanning, SSCC/NVE

Export & transport documents

EDI integration

Production scheduling & control panel

Weighing scale integration (weight & dispense)

Batch production

Machine/system integration

Yaveon 365 tracks every batch from warehouse receiving through processing steps to storage and shipment. Expiry dates and batch data are automatically recorded. Additionally, detailed traceability reports provide structured recall lists and audit-proof documentation for quality audits.

Yaveon 365 versions, calculates, and centrally manages recipes. You can precisely control tolerances or raw material substitutions. Nutritional values, additives, and declaration-relevant information are automatically available for labels, specifications, and product data.

Yaveon 365 integrates inspection plans, CCP documentation, and audit trails directly into the process. The industry-specific ERP automatically captures measurements such as moisture, temperature, or metal testing. Digital proofs and standardized reports simplify certifications according to HACCP, QS, or GMP+ and ensure your company is audit-ready.

Yes. Framework and call-off contracts, pricing logics, and multiple currencies can be fully represented. Recipe and raw material costs remain transparent at all times, while you can flexibly integrate workflows for price protection and costing.

The solution automatically compares certificates of analysis (COA) with the specifications for each batch. If there are discrepancies, the system initiates predefined workflows for quality control. Supplier status, certificates, and audit results are securely documented and linked to approvals for maximum quality assurance.

Yes. Catch weight processes for bulk goods and raw materials, as well as flexible packaging hierarchies such as bags, sacks, trays, cartons, or pallets, are fully integrated. Yaveon 365 automatically generates SSCC and GS1 labels, including shelf life and batch information, from the master data.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

Everything about food safety audits – Beitrag öffnen

Everything about food safety audits – Beitrag öffnen

Comprehensive guide to food safety audits that protects consumers and supports GFSI compliance.