See how quality control keeps food safe and consistent through testing and regulatory standards.

Complete batches: Transparency from catch to delivery

Precise processes: catch weight, multi-level units & scale

Highest compliance: Meets HACCP and GMP+ requirements

Lot and origin verification including FAO and catch area

Capture of vessel, port, and trip information

Support for traceability standards like GDST

Recall workflows with blocks and partner notification

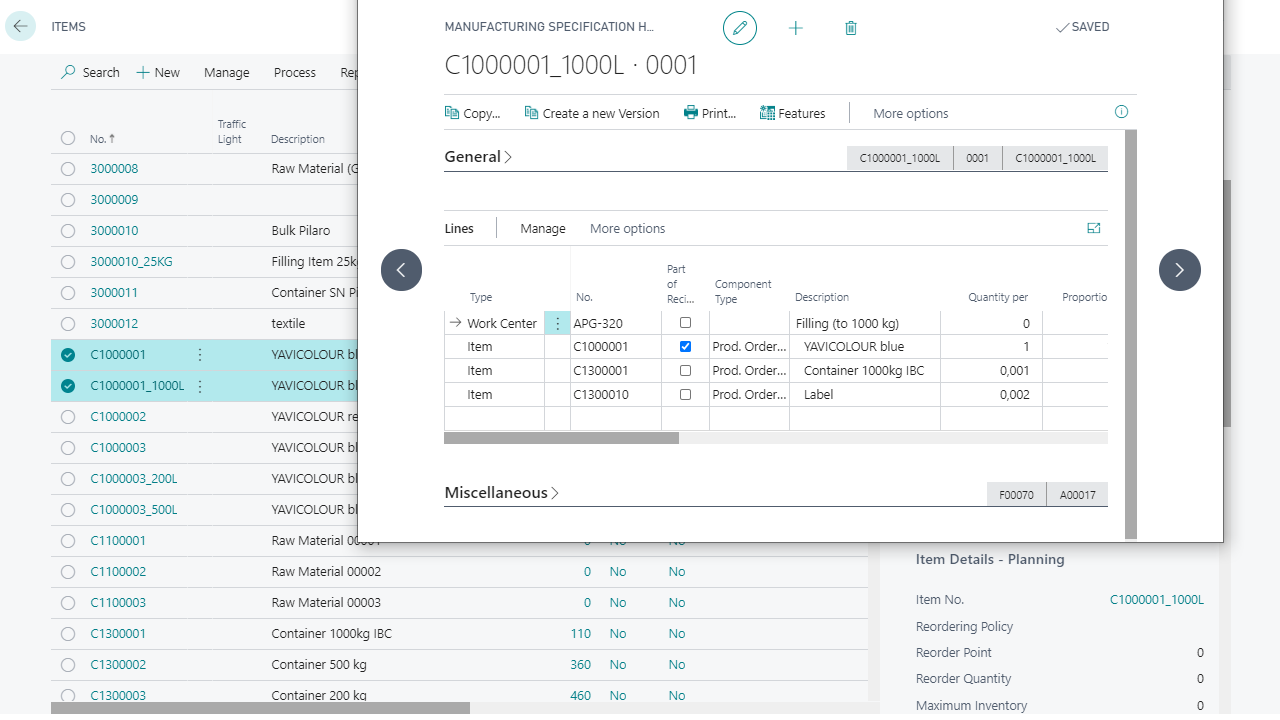

Inverted/reverse BOM for blanks and byproducts

Yield and margin tracking per production step

Resource planning and production calendar

Reporting down to the batch and lot level

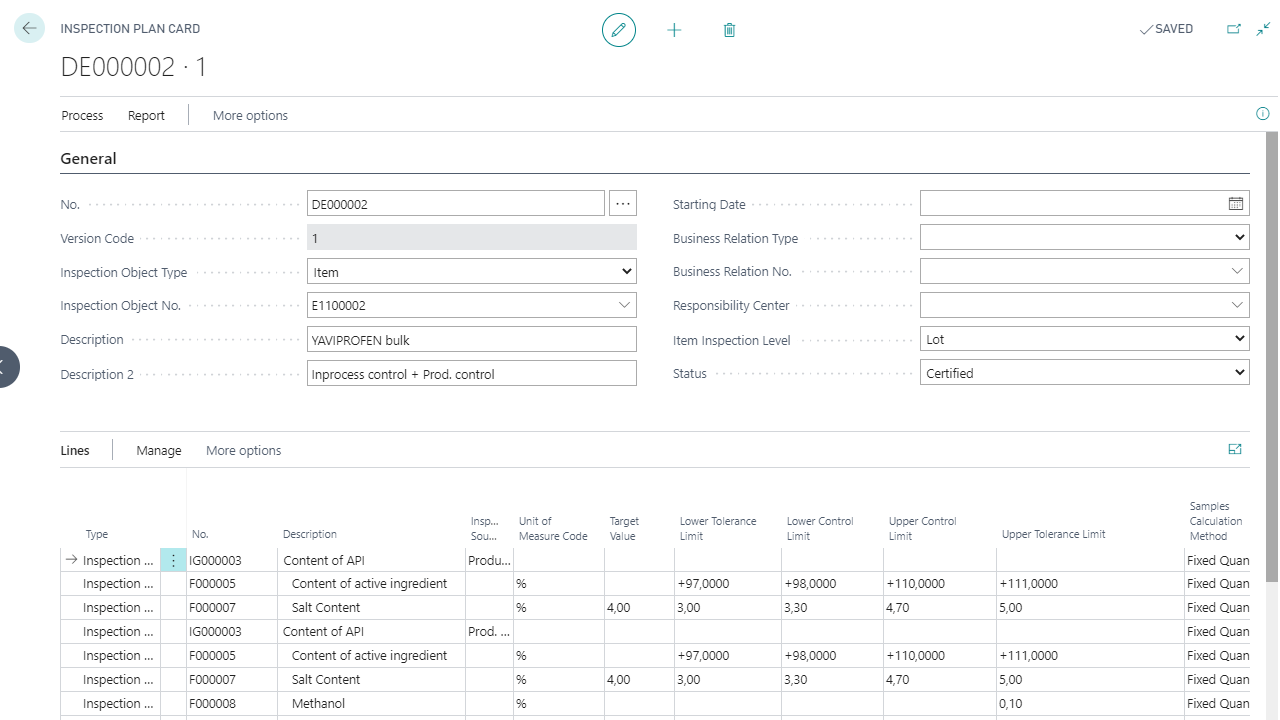

Inspection plans, checklists, and block/release

Integrated support for HACCP/GFSI/FSMA

COA and certificate generation

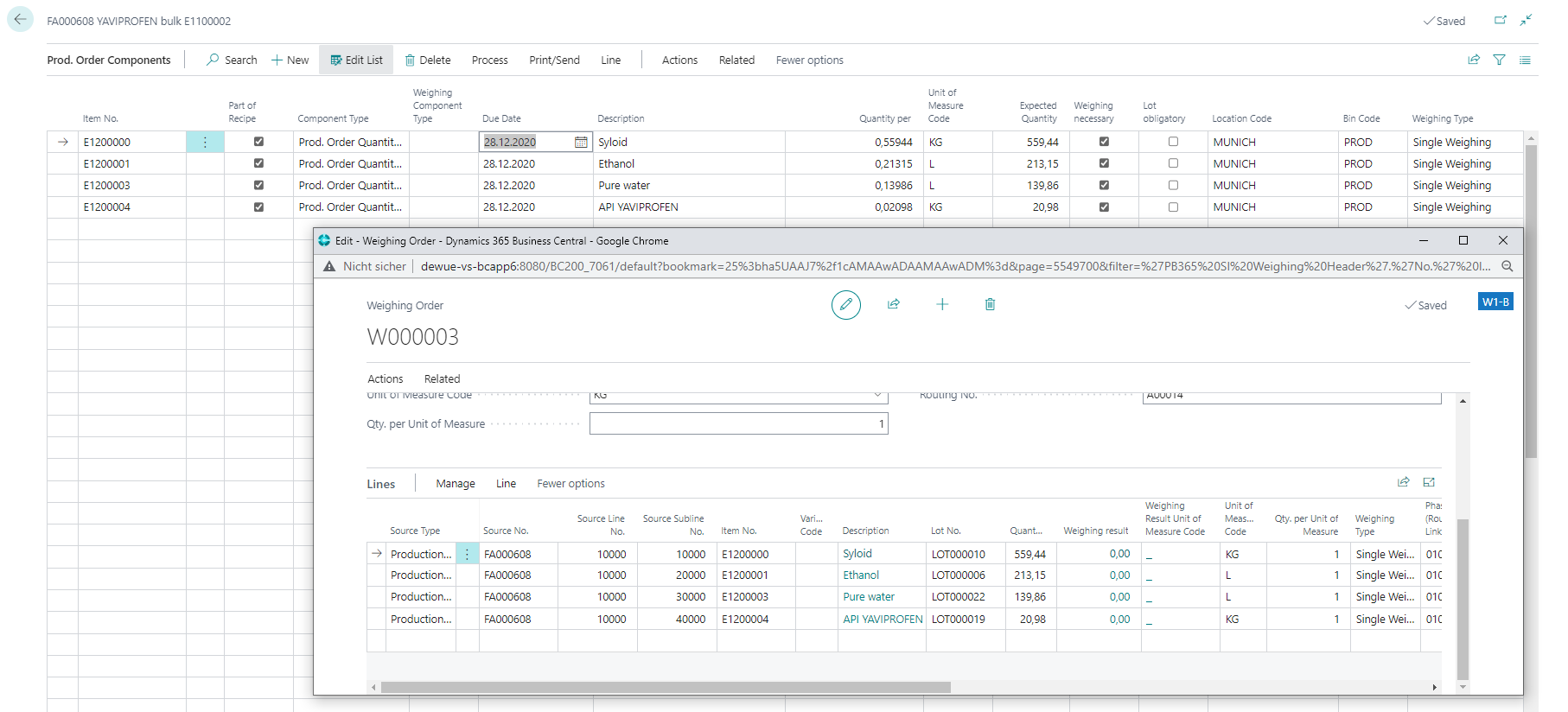

Mobile QC and device/weighing scale integration

Catch weight handling across all process stages

Multiple units per transaction (kg/carton/item)

Automatic weight recording at packing stations

Price and costing logic by weight & container

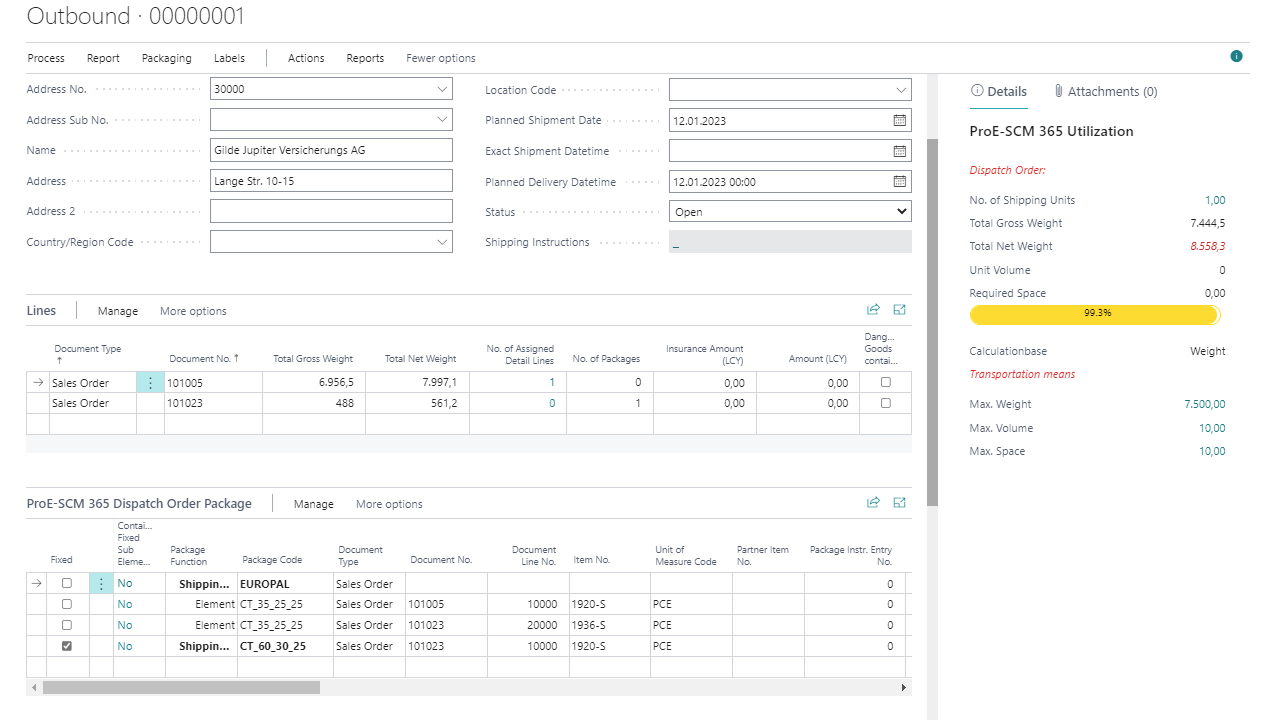

Scanner-guided warehouse processes and bin management

Licensee/SSCC (GS1-128) for shipping units

Route planning with proof of delivery

Export, customs, and cold store documentation

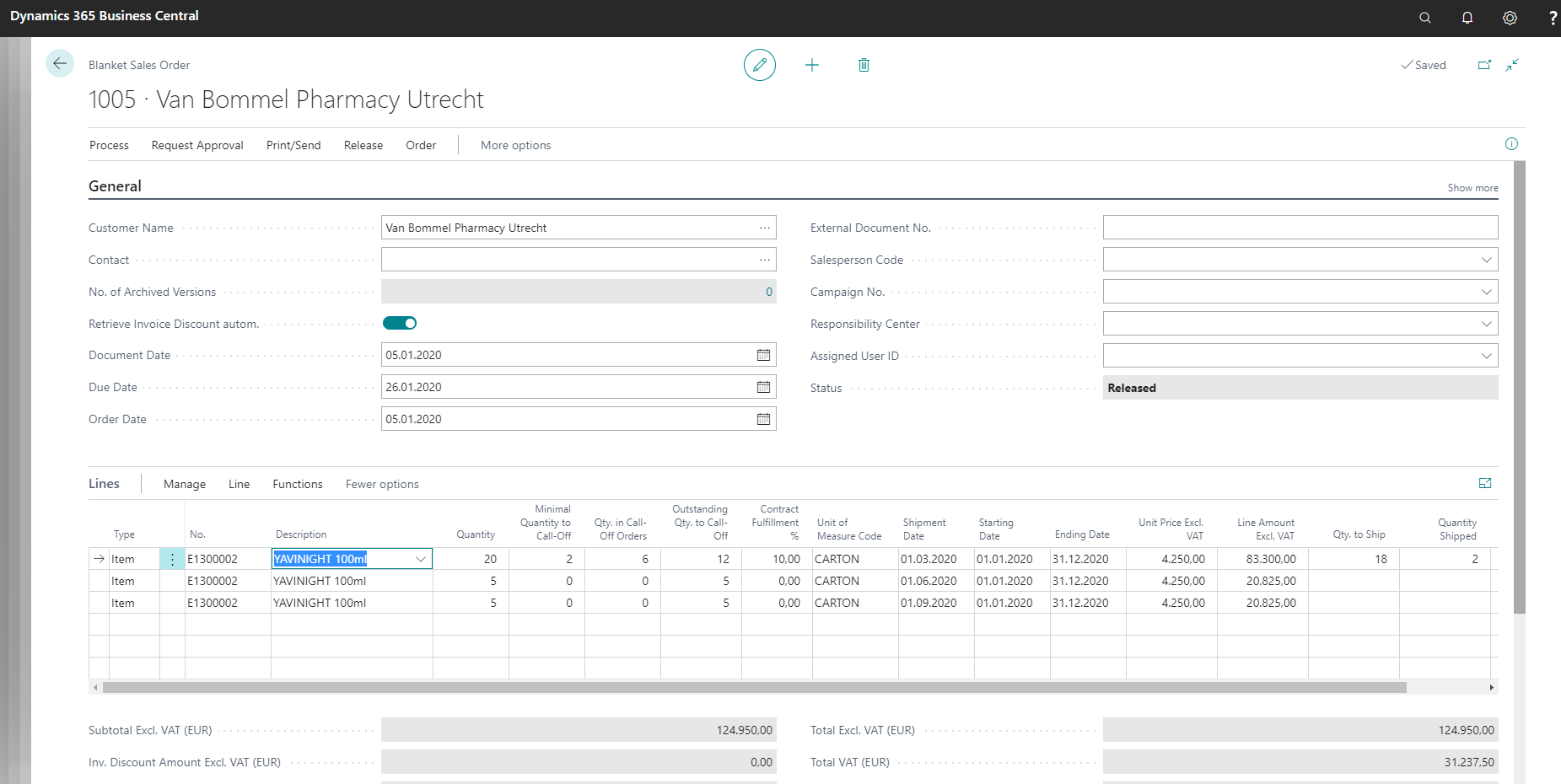

Blanket orders & MRP planning

Landed cost distribution by weight, volume, or unit

Price, discount, and commission logics

EDI integration for purchasing and sales

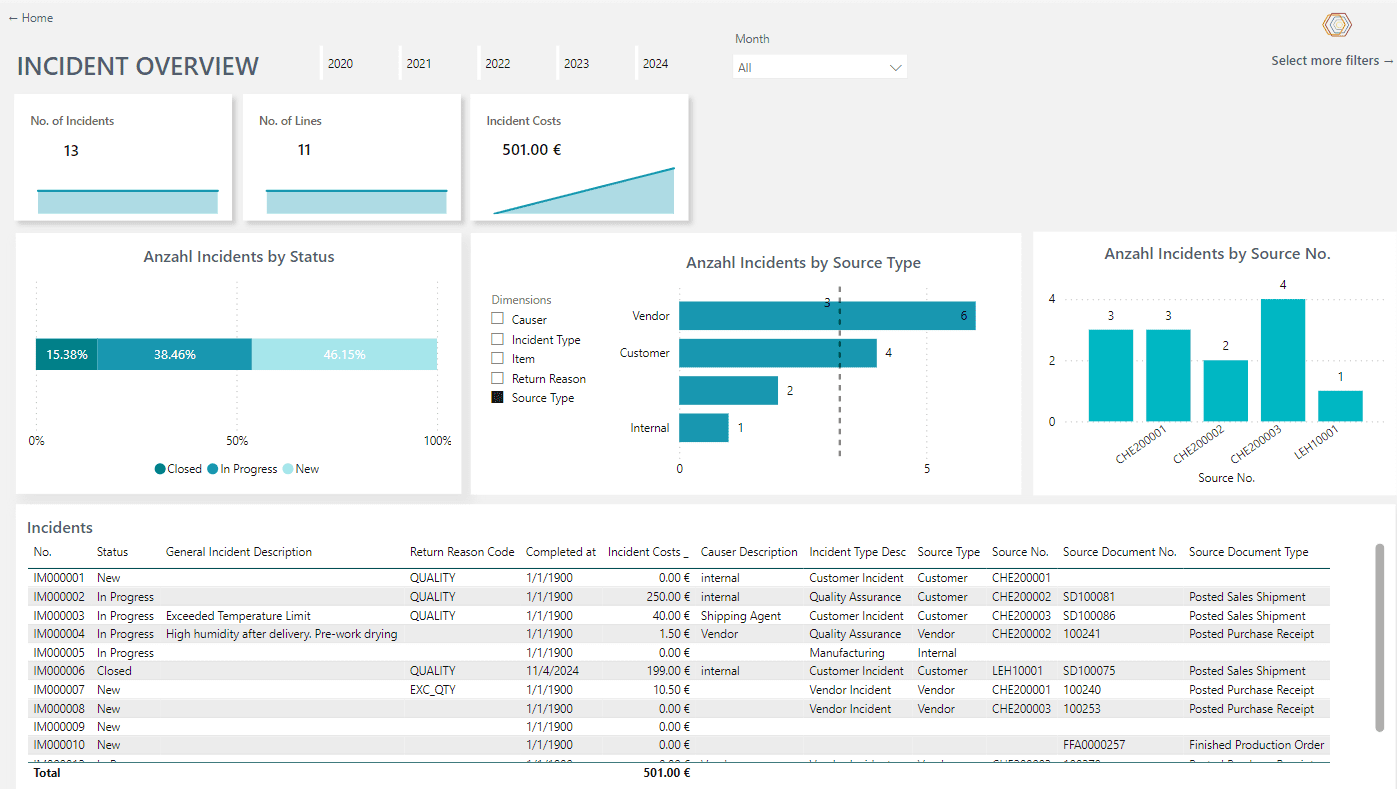

Batch and lot reports with aging analysis

Production, inventory, and sales KPIs

Quality audit and compliance reports (HACCP, FSMA, GFSI)

CO₂/green accounting for goods flows

Yaveon 365 stores all relevant catch data, including ship, fishing area, and method, directly in the batches. Recall workflows and block functions ensure comprehensive traceability from source to customer.

Yaveon 365 automatically imports weighing data from production. Glaze, drip, and net weights are incorporated into costing, yield, and inventory valuation, forming the basis for precise cost and margin transparency.

The ERP digitally documents inspection plans, limits, and sampling. In the event of a deviation, quarantine and CAPA processes are automatically initiated and tracked in an audit-secure manner.

The distribution of landed costs is automatic based on weight, volume, or units. All relevant import and customs documents are directly stored in the system for each shipment and batch.

The ERP solution captures temperature and time data in real-time, assigning them to storage zones and shipments. FEFO and remaining shelf life guide order picking to ensure product quality and freshness are maintained.

SSCC/GS1 labels provide a unique identification for shipping units. Label printing, tracking, and EDI-ASN are done directly from warehouse receiving, production, or shipment to ensure full transparency until delivery.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

Everything about food safety audits – Beitrag öffnen

Everything about food safety audits – Beitrag öffnen

Comprehensive guide to food safety audits that protects consumers and supports GFSI compliance.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.