Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Full control: Traceable from warehouse receiving to customer

Reliable compliance: Meets IFS, BRC, HACCP requirements

Efficient supply chain: Manages inventory, production, and logistics

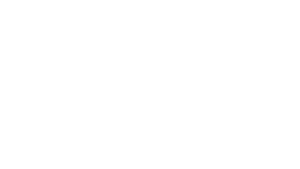

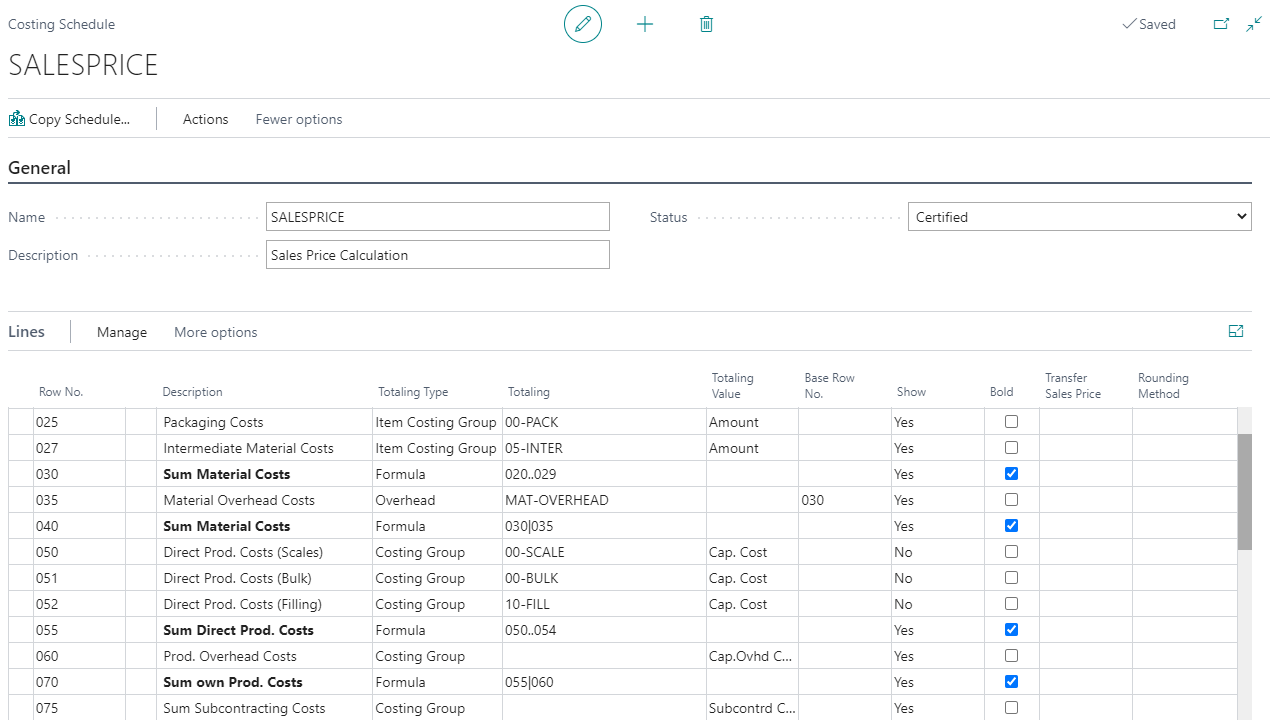

Management of chip, nut, and bar recipes

Automated allergen labeling

Nutritional value and cost calculation

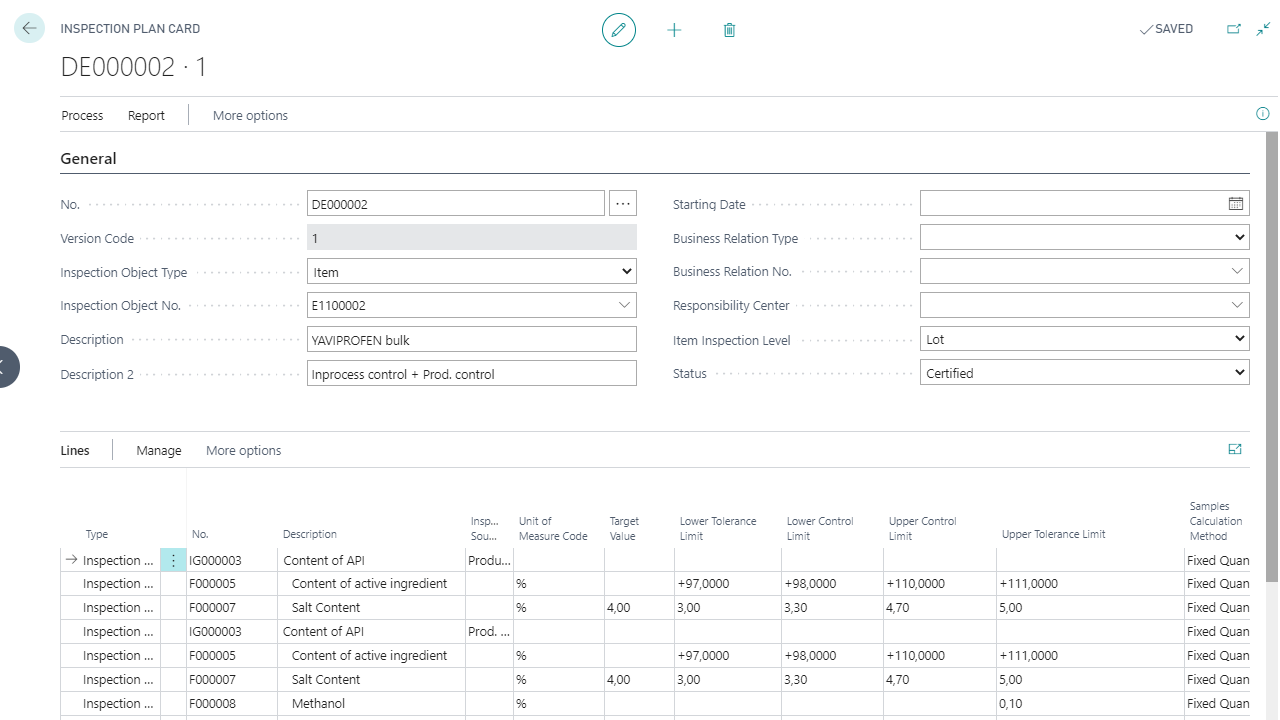

Flexible variant and edition control

Comprehensive lot tracking

Shelf life and best-before date monitoring

Recall management in seconds

FIFO/FEFO warehouse processes

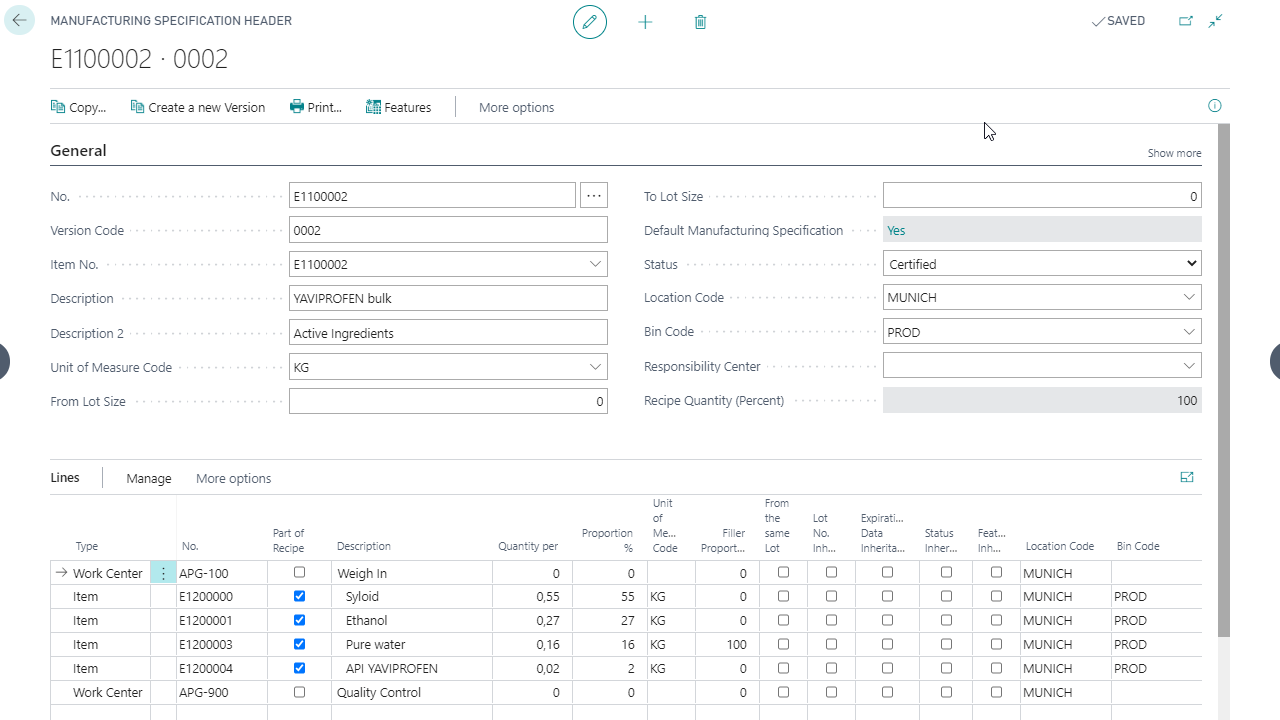

Sensory tests (taste, texture, crispness)

Fat and moisture controls

In-process controls in manufacturing

Incoming goods inspection of raw materials

Planning variable batch sizes

Optimal utilization of ovens & deep fryers

Flexibly control packaging lines

Reduce waste and costs

Route and tour optimization

Transparent delivery date management

Export and customs processing

Seamless integration with ERP data

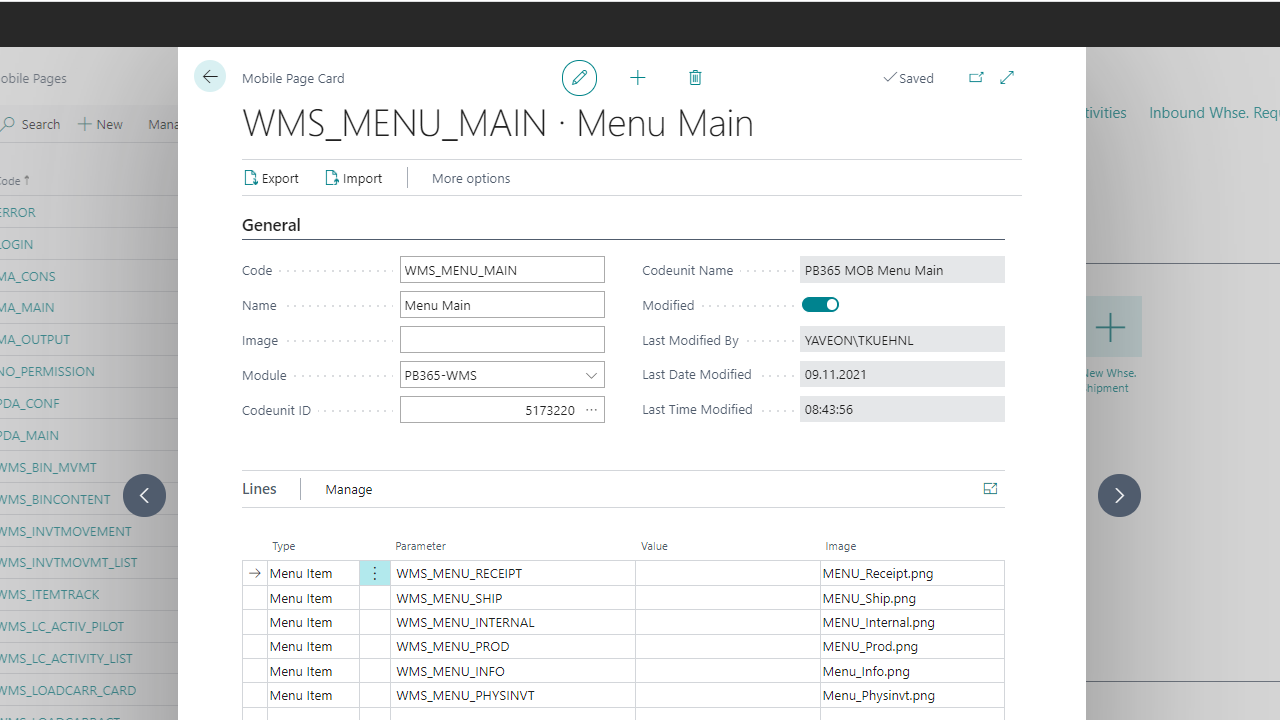

Mobile scanning solutions

Error-free transfers

FIFO/FEFO-controlled processes

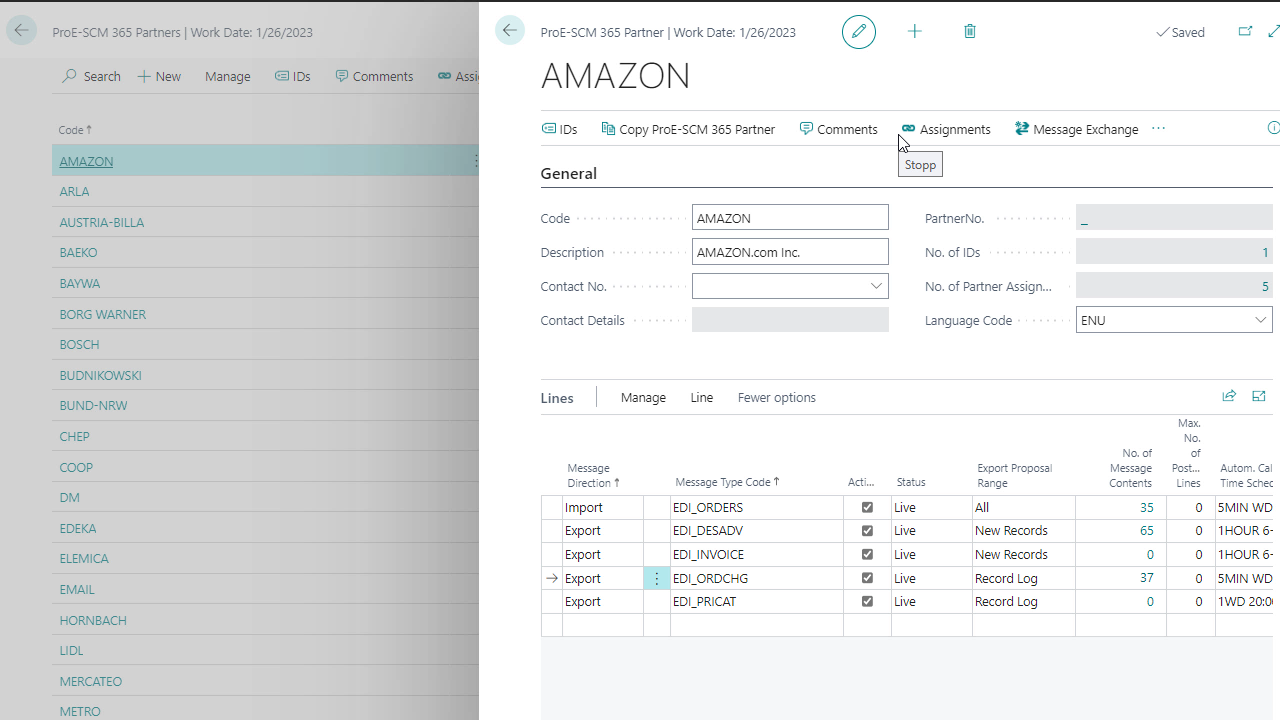

Central management of master data, such as GTINs, EANs, and UPCs

Data reconciliation between shipments and invoices

Transfer of purchase orders, invoices, and remittance advice

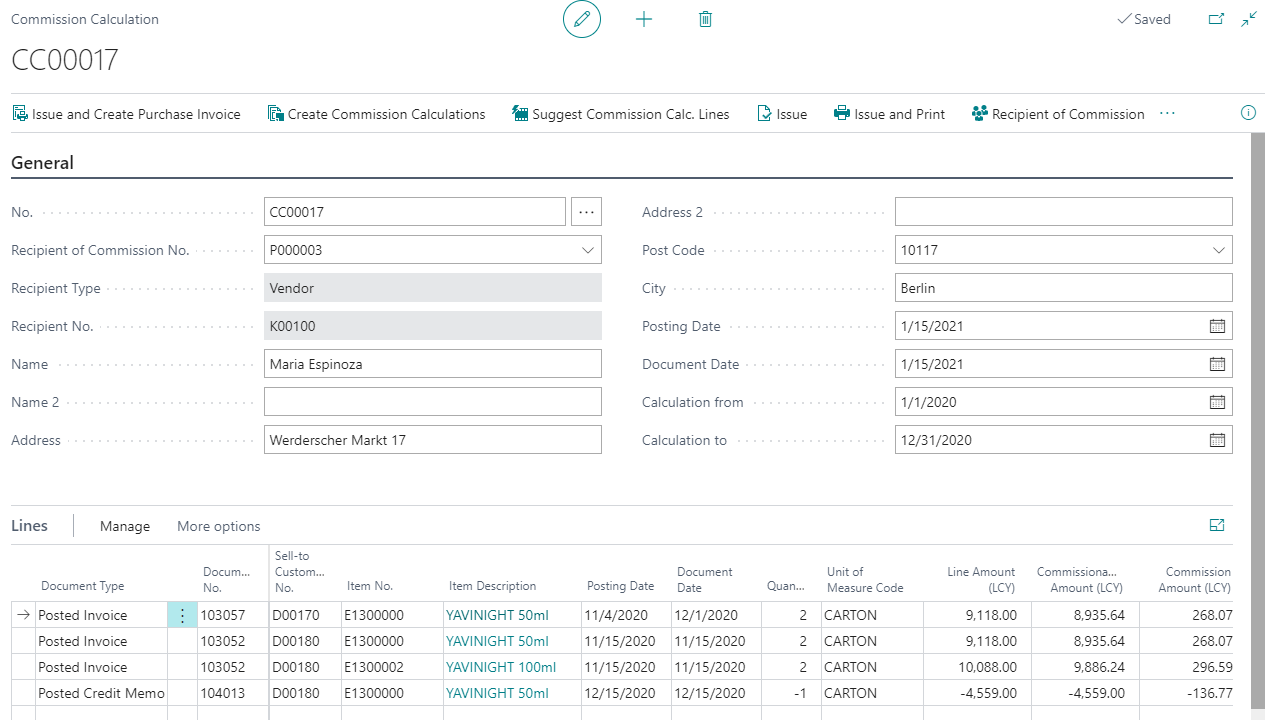

Flexible discounts, surcharges, and credits

Import and centralized management of item catalogs

Flexible control through trade-relevant item groups

Transparent conditions with central price overview

Inspection of listings to prevent incorrect deliveries

Tiered pricing and discounts through customer hierarchies

With Yaveon 365, all raw materials, batches, and finished products are comprehensively documented from warehouse receiving to shipment. Recalls can be precisely managed in seconds, ensuring safety and trust for successful audits and satisfied customers.

The system identifies and monitors allergens such as nuts or gluten in every ingredient. It ensures clear separation during storage and production, generates automatic alerts, and guarantees compliant labeling on packages.

With Yaveon 365, you can account for capacity, seasonal demand, and raw material availability in real time. This allows you to optimally plan shifts, machines, and batch sizes, avoid bottlenecks, and reliably meet delivery deadlines.

From in-process controls during production to inspection plans for sensory tests and shelf life: Yaveon 365 for the snack industry documents every step, ensuring consistently high product quality that is fully auditable and transparent.

The industry-specific ERP solution provides real-time transparency over raw materials, semi-finished products, and finished goods. Methods like FIFO and automatic batch rotation prevent overstocking, reduce waste, and ensure product freshness.

Yes, packaging variants such as single packs, multipacks, or promotional designs can be implemented flexibly. Yaveon 365 automatically generates legally compliant labels with nutritional values, allergens, and expiration dates.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

5 tips how you can avoid recalls – Beitrag öffnen

5 tips how you can avoid recalls – Beitrag öffnen

Our paper provides 5 tips for the process industry: How to prevent recalls and ensure full batch traceability.