See how quality control keeps food safe and consistent through testing and regulatory standards.

Seamless security: traceability & best-before date management

Consistent quality: Integrated inspection processes following HACCP/IFS/BRC

Reliable coordination: processes with dependable planned/actual data

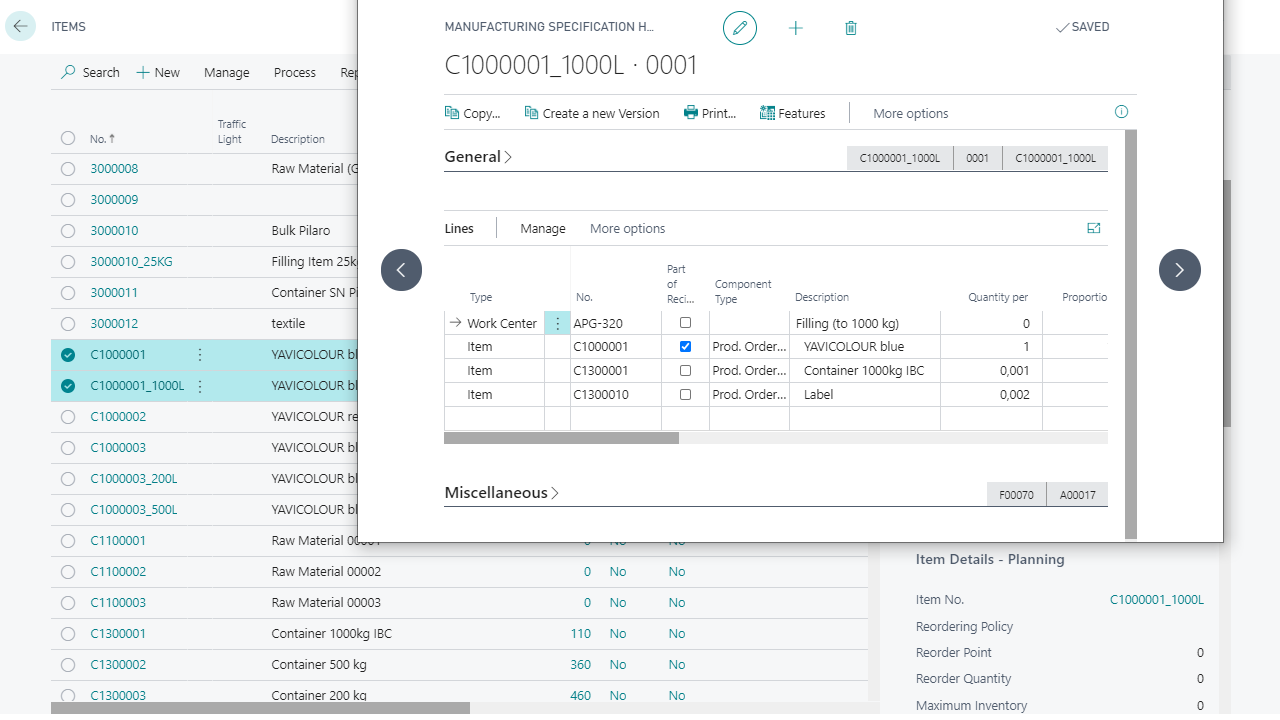

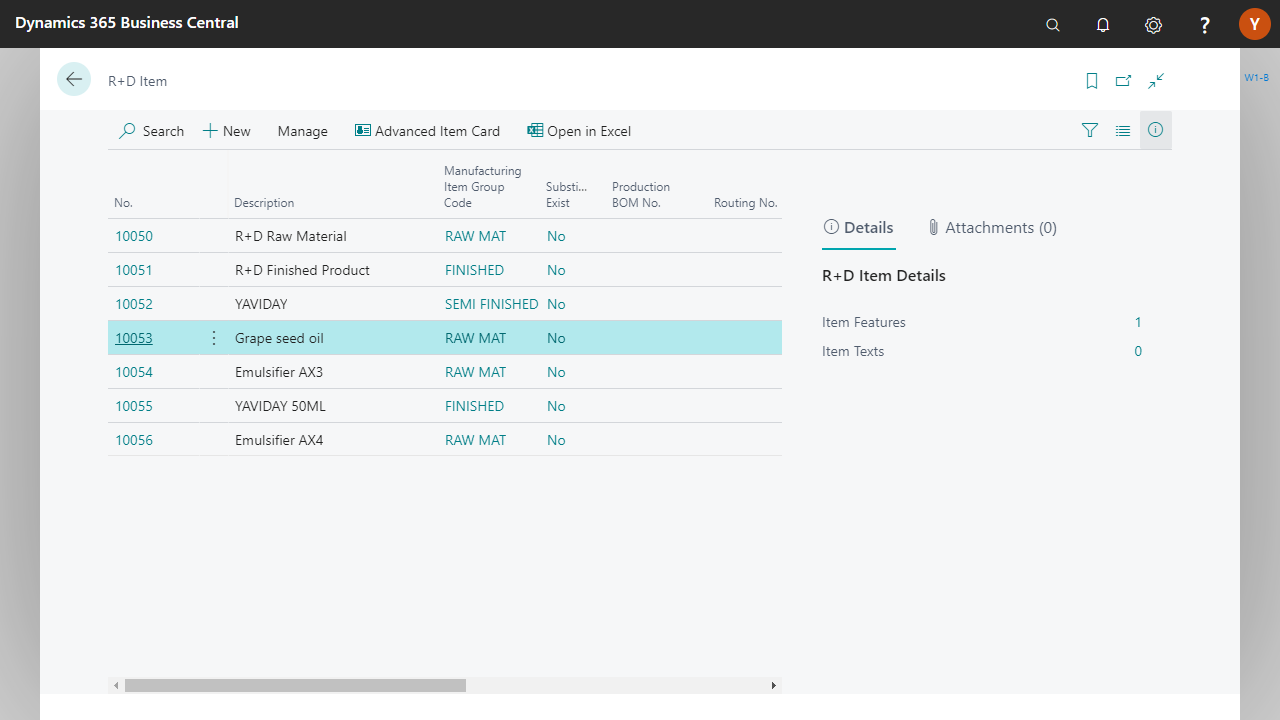

Multilevel recipes and variants

Demand planning across all material management areas

Production optimization including personnel & machines

Optional: Shop floor/MES feedback for actual consumption

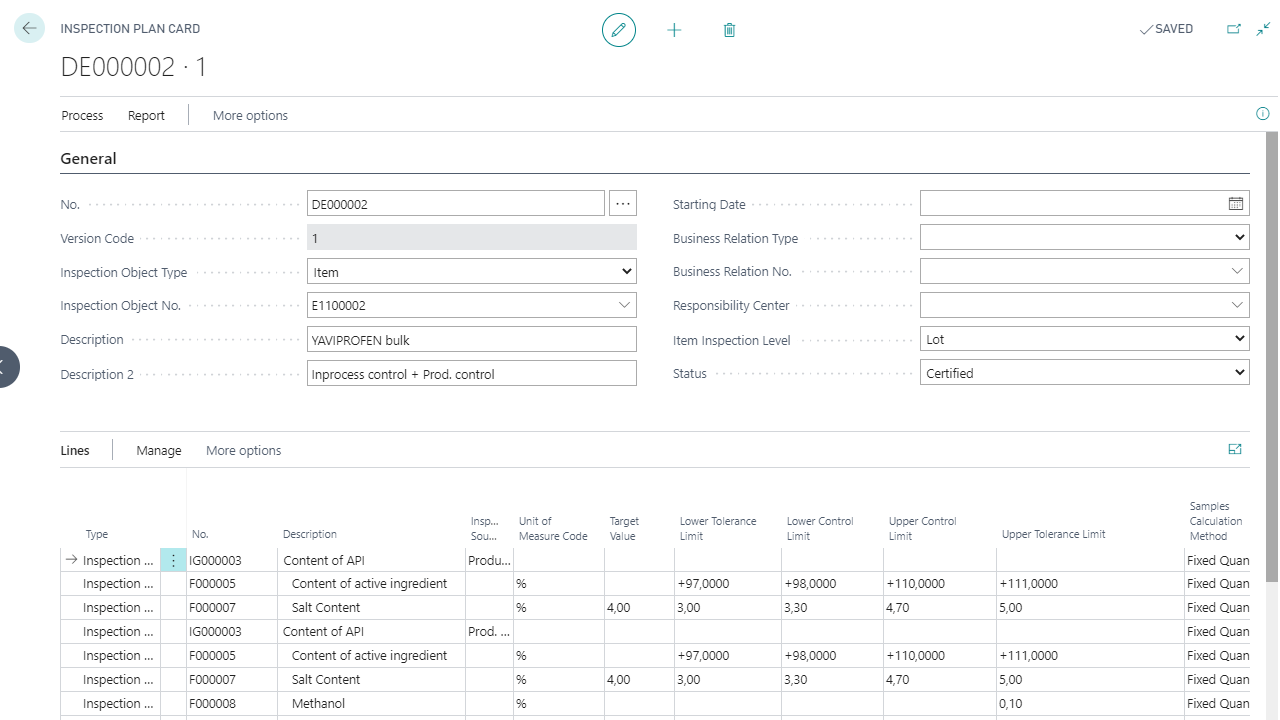

Incoming goods, in-process, and final inspections

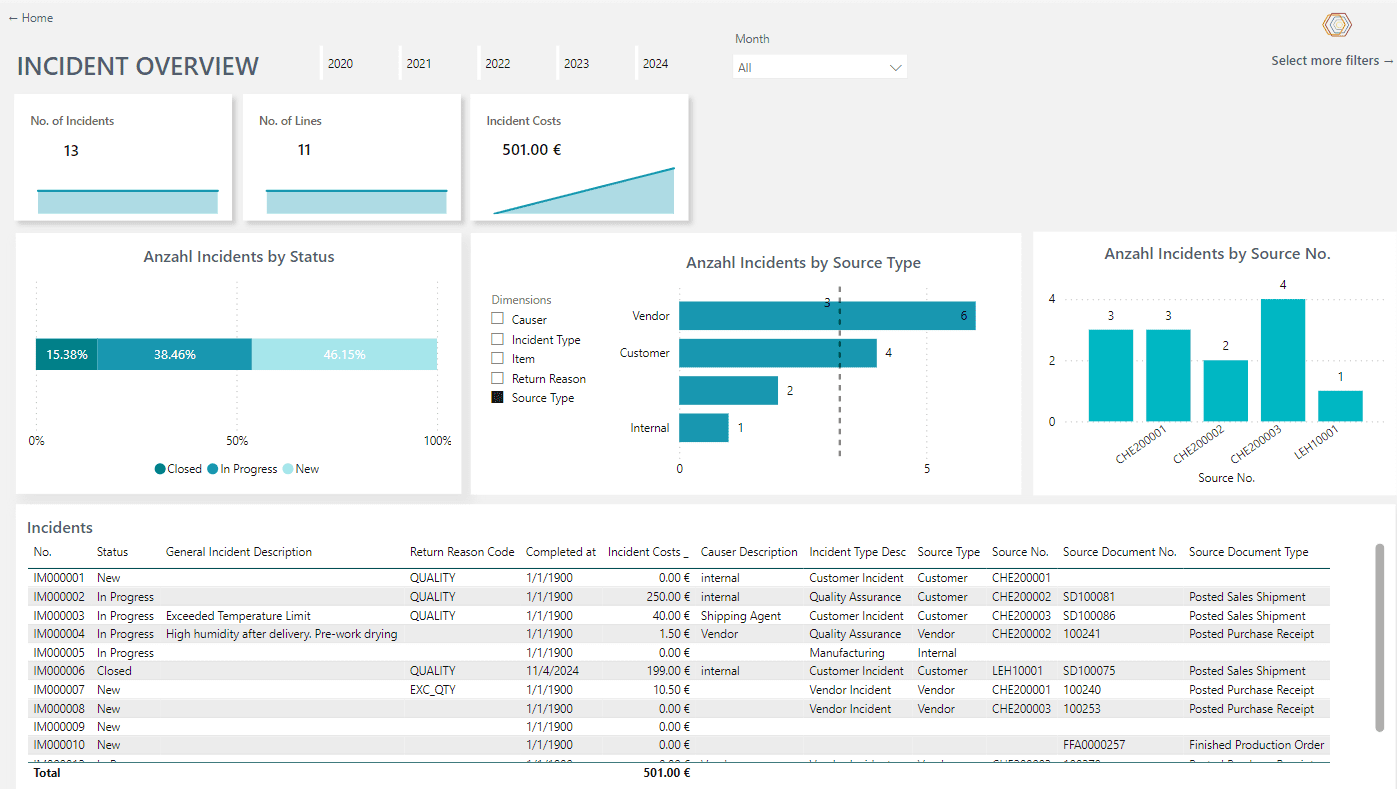

Documented deviation and action management

Supplier and batch documentation

Standards like HACCP and IFS/BRC integrated

Batch profiles with origin, production date, and supplier

Forward and backward tracing down to the position level

Expiration management with warnings

Recall simulation & documentation for each batch

Product specifications as a data source

Allergen, nutritional, and origin information according to LMIV

Layouts for individual customers and trades

Documents such as specifications & certificates of conformity

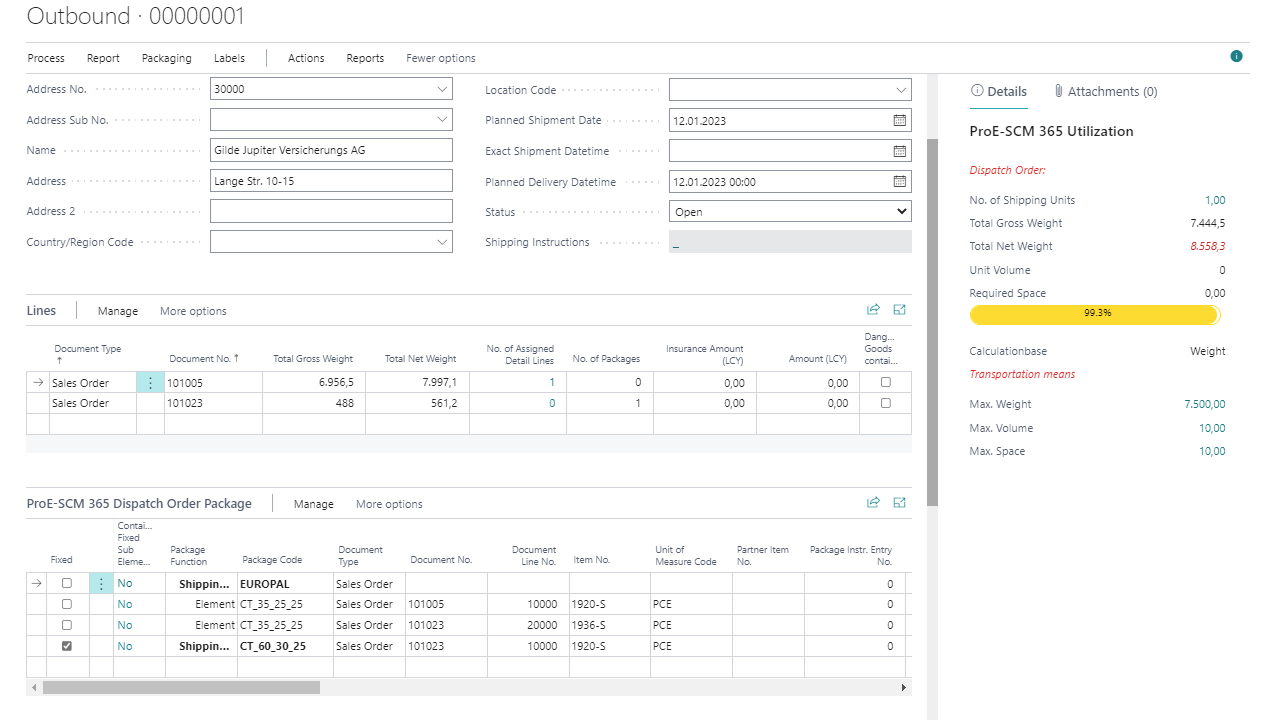

Mobile warehouse processes from storage to packaging

SSCC serial numbers & EDI transfer

Container and packaging management including deposits

Pick order based on expiration date and temperature requirements

Supplier evaluation and qualification

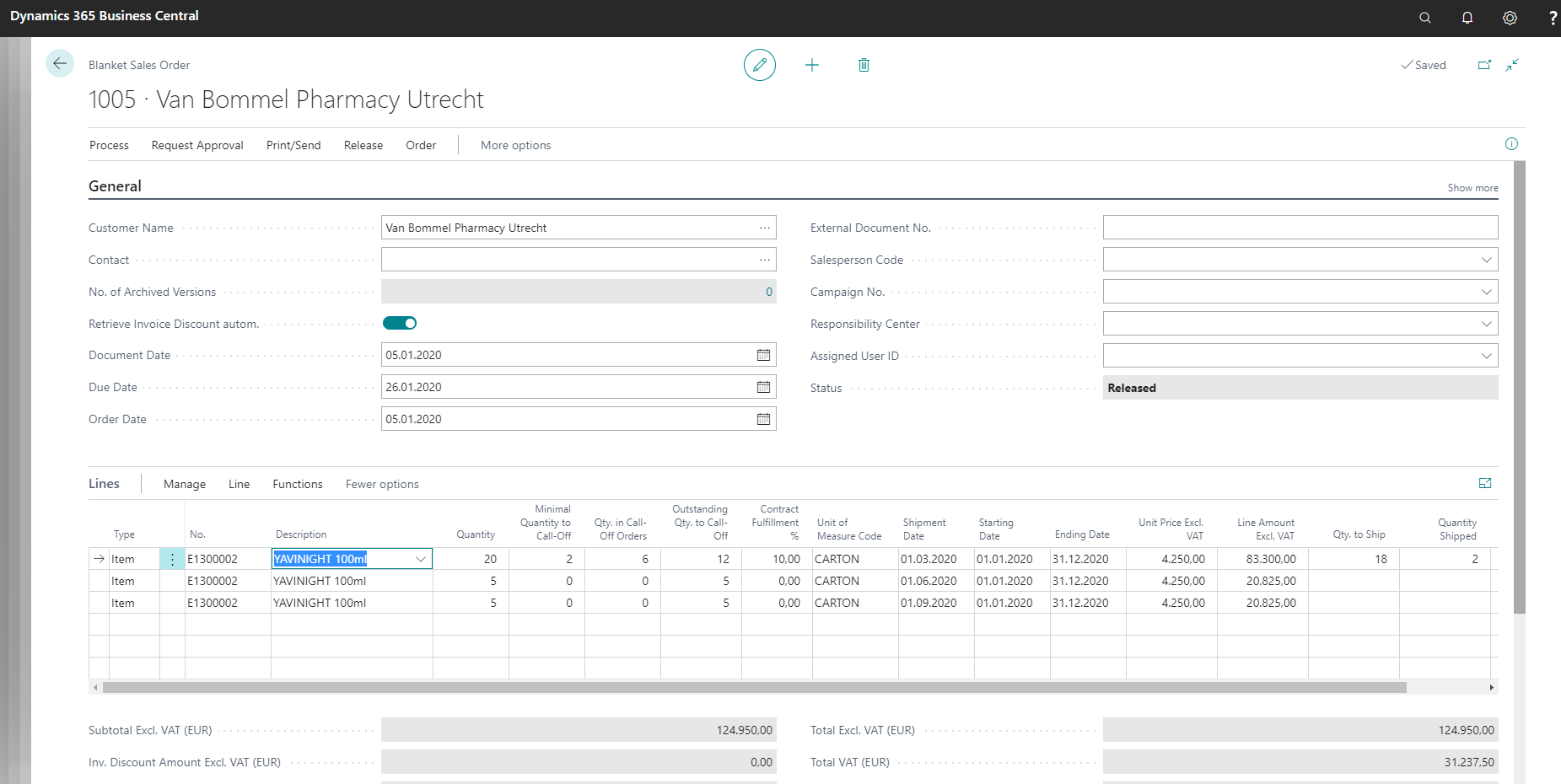

Vendor/supplier invoicing, contracts

Flexible pricing and discount logics

Incoming goods inspection with hold/release status

Production and batch KPIs (yield, scrap, OEE)

Inventory coverage & expiration date risks

Sales and condition analysis

Management dashboards for audit-relevant KPIs

Yaveon 365 automatically links every batch and sub-batch with all relevant process steps—from warehouse receiving, preparation, and mixing to filling, storage movements, and shipment. Origin and inspection data are directly included. Using forward and backward search, affected items can be quickly identified, and recall lists are available at the push of a button.

Formulations are versioned and go through clear approval processes. All declaration and allergen information is sourced directly from the stored data and automatically transferred to the appropriate label layouts, including customer-specific variants and container sizes.

Yaveon 365 supports secure operations through defined zones, cleaning and inspection plans, and mandatory approval levels. Deviations or suspected issues are recorded, documented, and systematically addressed through CAPA measures.

Remaining shelf life, expiration date data, and FEFO rules automatically manage inventory, order picking, and returns. The system ensures that products with critical freshness are used or shipped on time and prevents quality loss due to outdated goods.

Specifications and certificates of analysis (COA) are checked precisely for each batch. The results feed directly into the quality release process and automatically influence the supplier qualification status. This ensures you always have a clear view of the safety and reliability of your supply chains.

Catch-weight ensures precise management of variable weights, such as in antipasti or cheese, and maintains accurate inventory levels, pricing, and billing. SSCC codes uniquely identify shipping units and enable smooth logistics and EDI processes from the warehouse to retail.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.

Everything about food safety audits – Beitrag öffnen

Everything about food safety audits – Beitrag öffnen

Comprehensive guide to food safety audits that protects consumers and supports GFSI compliance.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.