Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

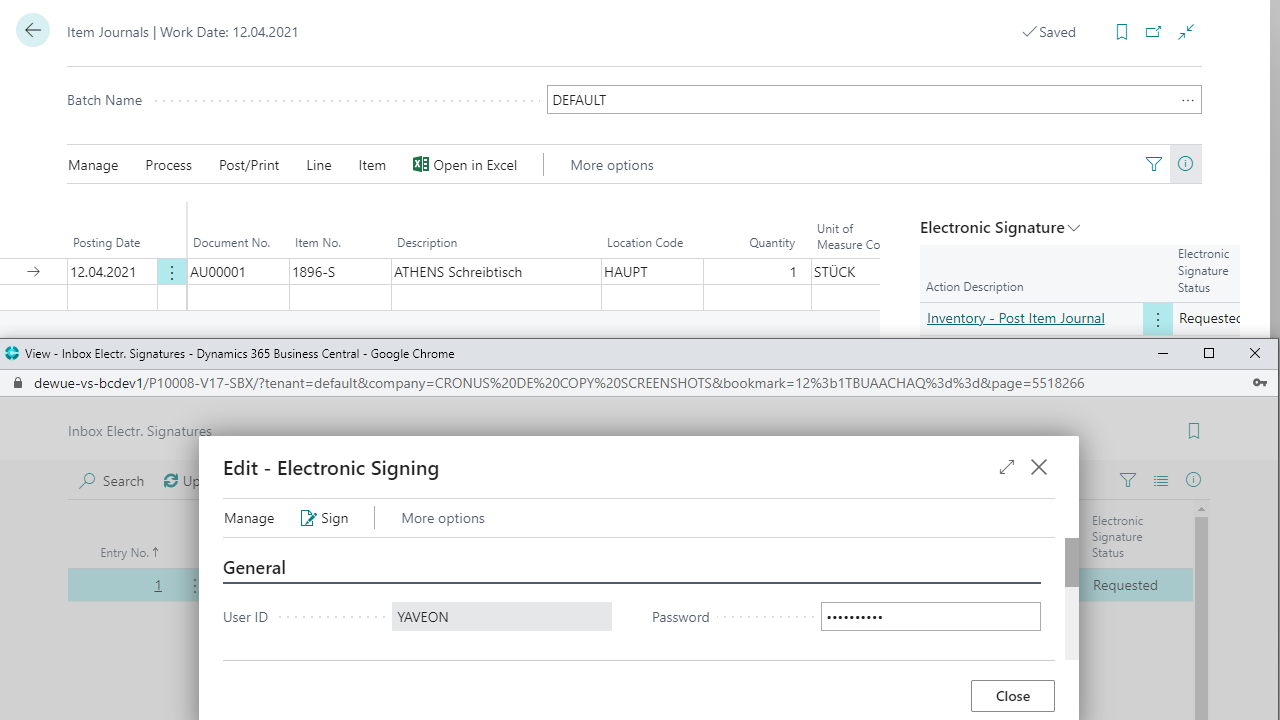

Complete transparency: batch and allergen management

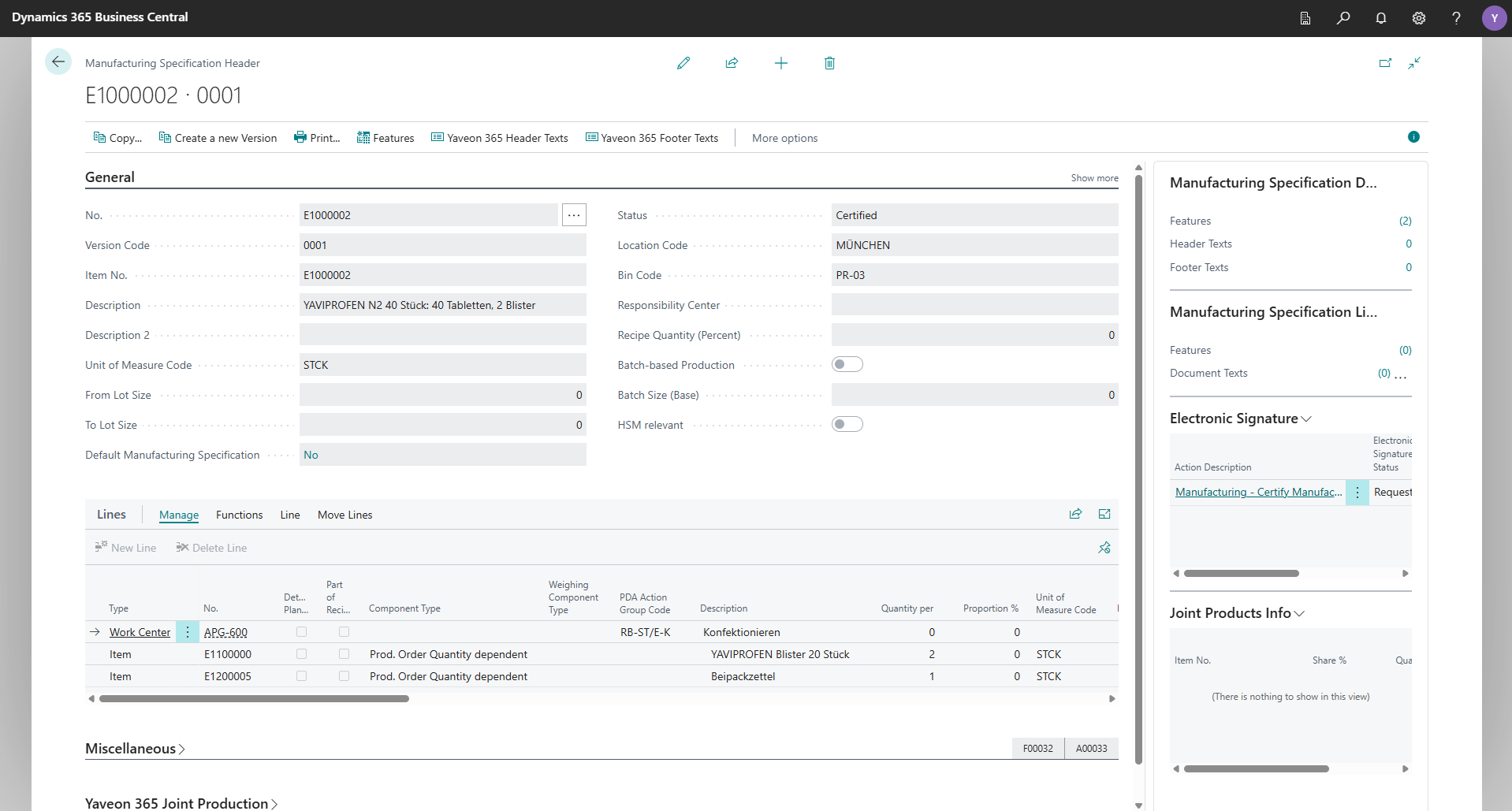

Total control: integrated recipe and bill of materials management

Precise execution: production, warehouse, and catch-weight processes

Forward and backward tracing down to the raw material level

Quarantine, hold reason, and release workflows

COA management & test certificates for customer orders

Recall lists, audit trail, and documentation packages

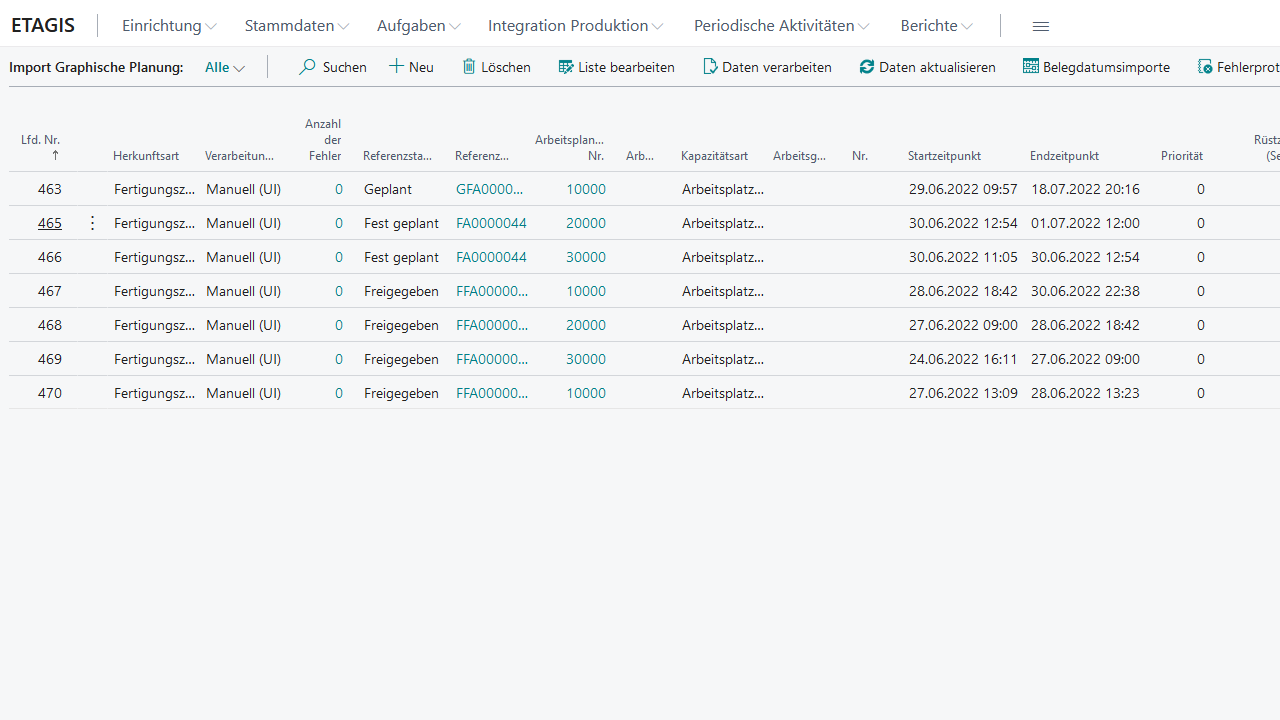

Batch/campaign planning, setup/washdown logic

Reservation of batch-specific components (FEFO)

WIP collection, mobile production feedback

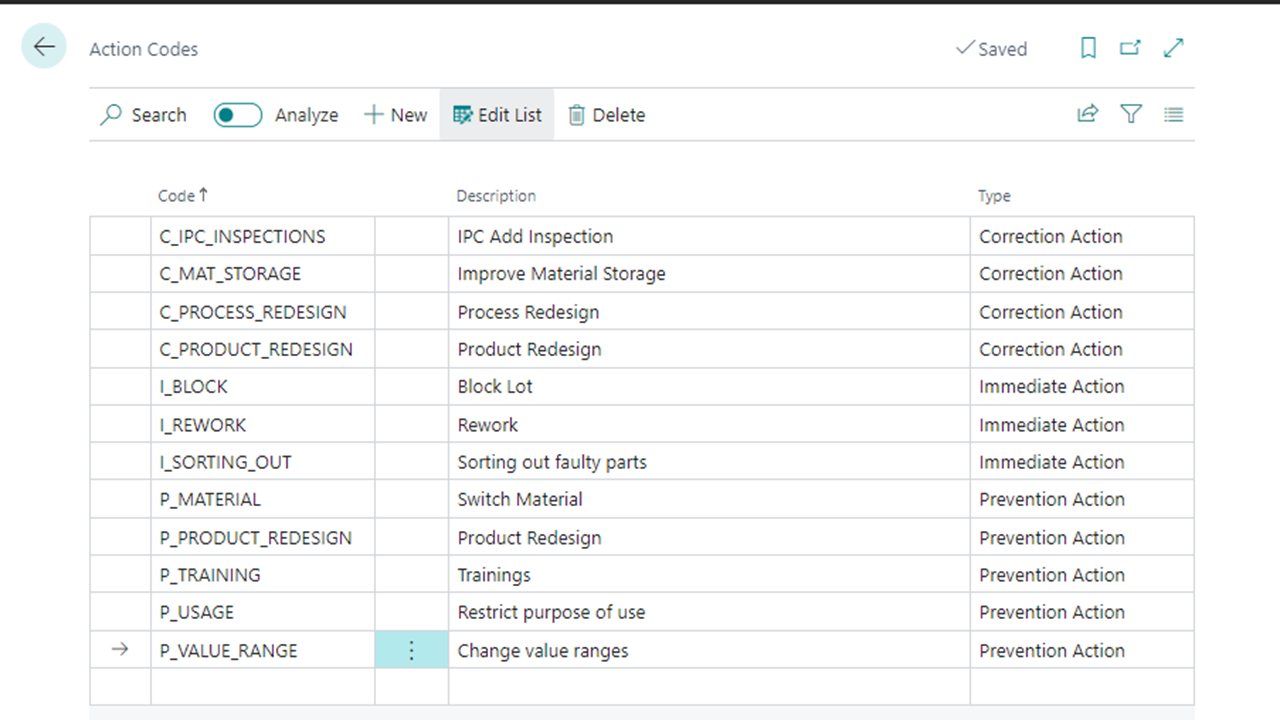

Deviation and non-conformance management

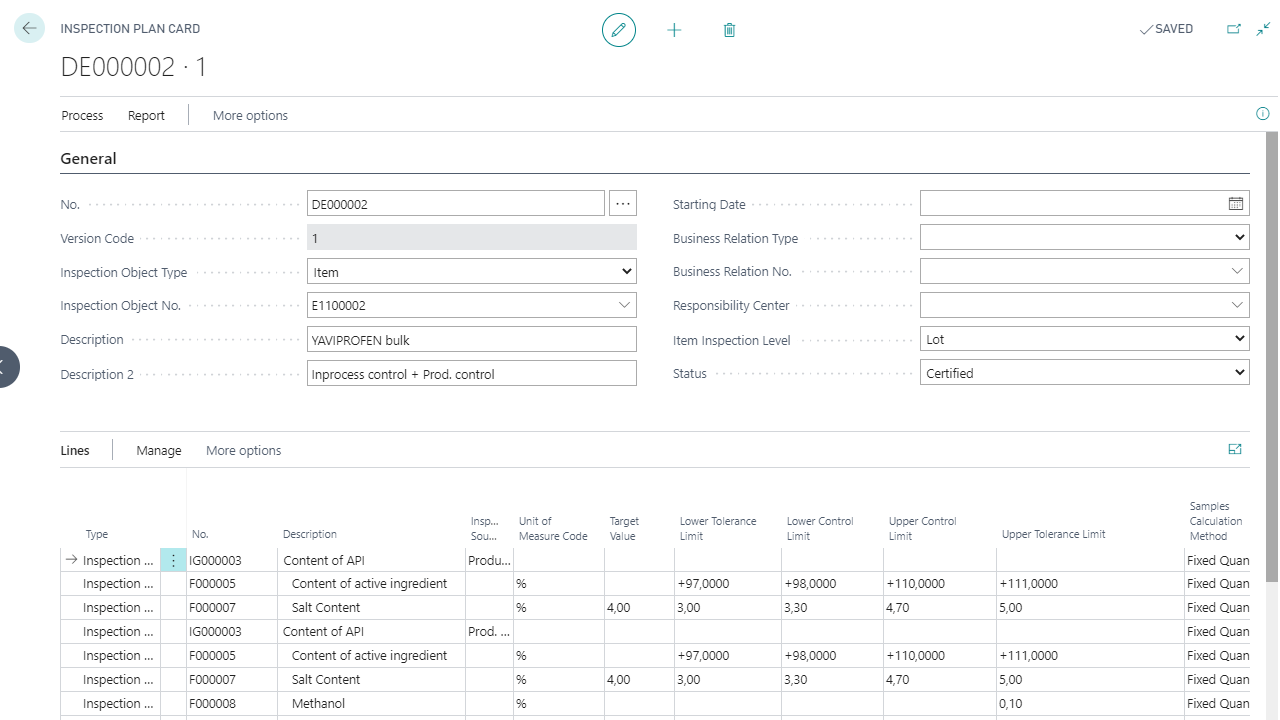

Inspection plans per material/formula, limits & AQL

Automatic lock/disposition for non-compliance

COA generation and certificate management

Trend analyses (e.g., sharpness, moisture, particle size)

FEFO, Best before date, shelf life tracking

Catch weight and variable weights

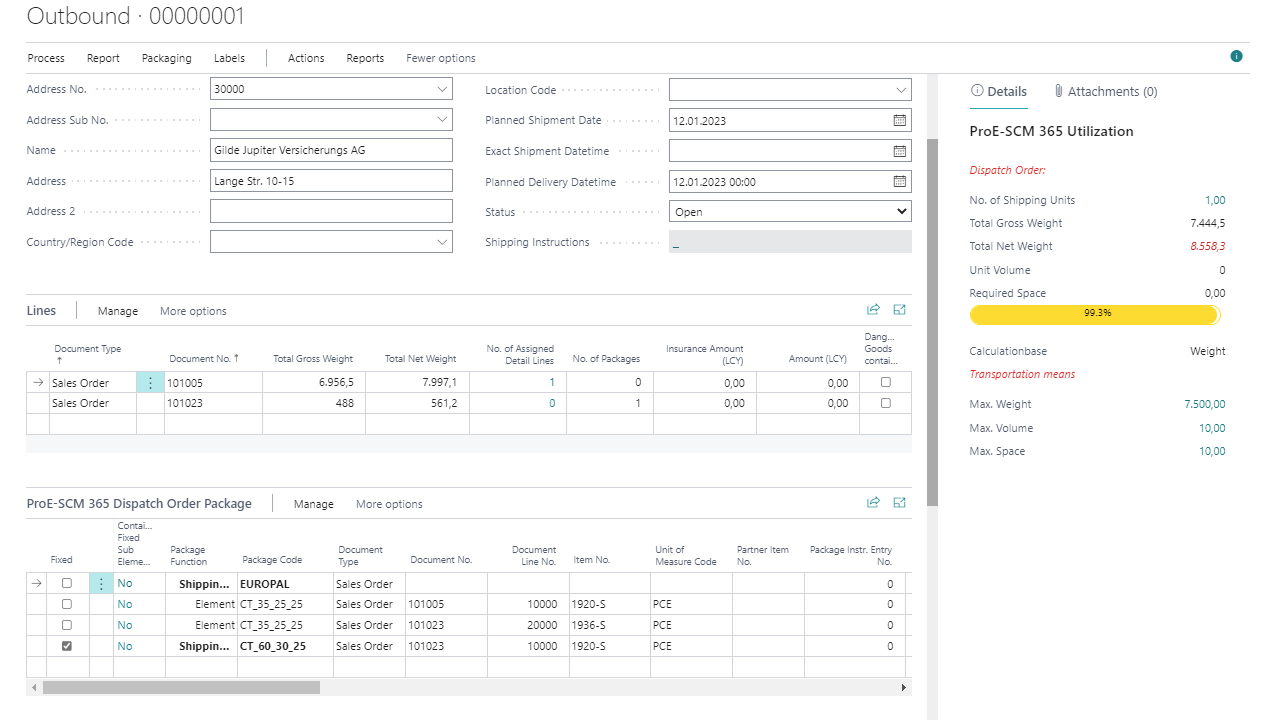

SSCC/EAN128 shipping labels, pallet handling

Inventory monitoring by batch, status, certification

MRP planning with lead times and minimum quantities

Availability check by batch/expiration date

Campaign formation to reduce setup and washing times

Purchase and production proposals with approval workflow

Allergen matrix, cleaning sequences, block/releases

Risk-based quarantine by origin/analysis

Production sequences by allergen/flavor groups

Documentation for HACCP, IFS, and BRC audits

Yaveon 365 thoroughly documents each batch from the origin of raw spices, through processing, to delivery. Recall lists, COA management, and a complete audit trail ensure transparency and traceability at all times.

Raw material inspections are integrated into the quality process: recording specifications, matching certificates of analysis, and providing proof of steam sterilization or germ reduction are conducted systematically. Block and release workflows ensure that only inspected materials are further processed.

Recipes contain defined target values for grind size and mixing parameters. During production, in-process controls and automatic feedback ensure consistent quality, optimal yield, and high homogeneity of spice blends.

The FEFO principle ("First Expired, First Out") ensures that inventory with the shortest shelf life is used first. Yaveon 365 takes warehouse conditions like light and temperature into account to ensure long-term aroma stability and product quality.

All relevant documents – from analyses and inspection reports to supplier certificates – are centrally managed in the system. Deviations automatically trigger blocks or CAPA actions, ensuring the authenticity and safety of your products.

Yaveon 365 offers flexible management of price and quantity agreements with durations, tiers, and index prices. This ensures transparency, planning reliability, and stable calculations, even with fluctuations raw material costs.

How to trace food and beverages safely – Beitrag öffnen

How to trace food and beverages safely – Beitrag öffnen

Traceability means being able to track food throughout its entire life cycle. We explain how you can guarantee this.

Everything about food safety audits – Beitrag öffnen

Everything about food safety audits – Beitrag öffnen

Comprehensive guide to food safety audits that protects consumers and supports GFSI compliance.

Quality control in food production – Beitrag öffnen

Quality control in food production – Beitrag öffnen

See how quality control keeps food safe and consistent through testing and regulatory standards.