How ERP systems in the medical device industry reduce costs through real-time monitoring and process optimization.

Comprehensive security: Documentation & traceability

Integrated compliance: Features for regulated processes

More time: faster development through automated processes

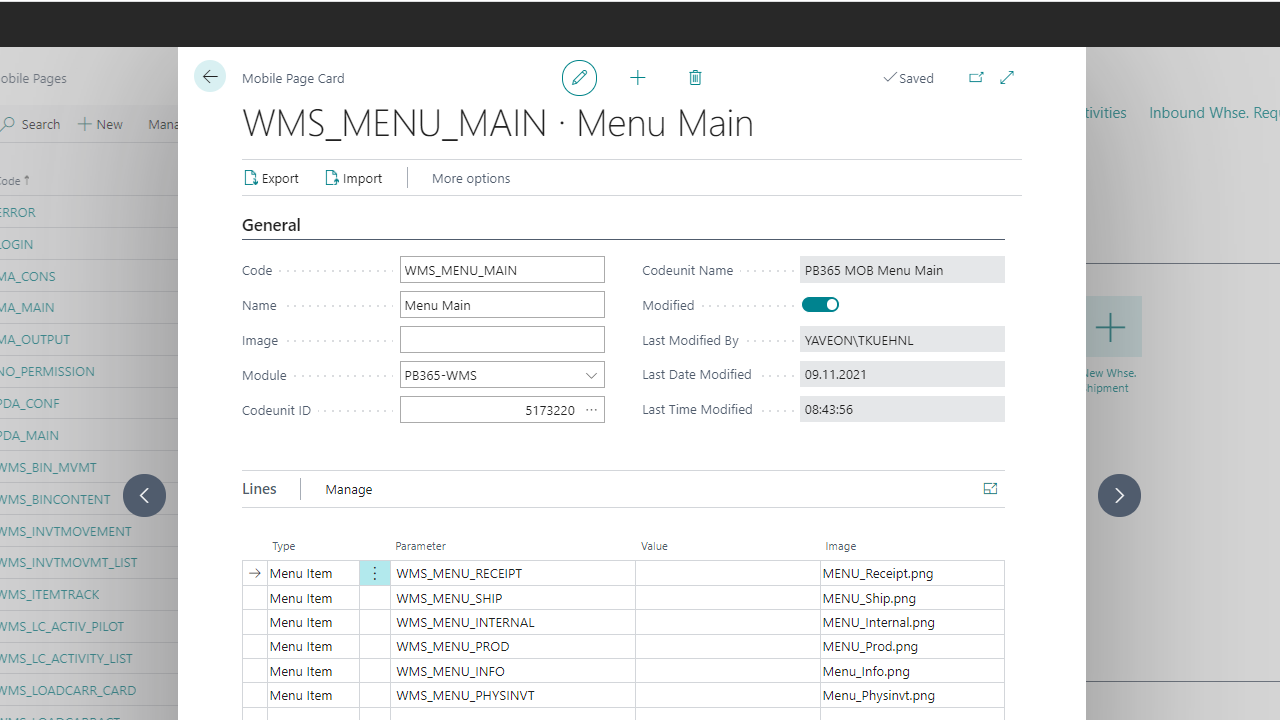

Permission sets & role center

Define incident types & error codes

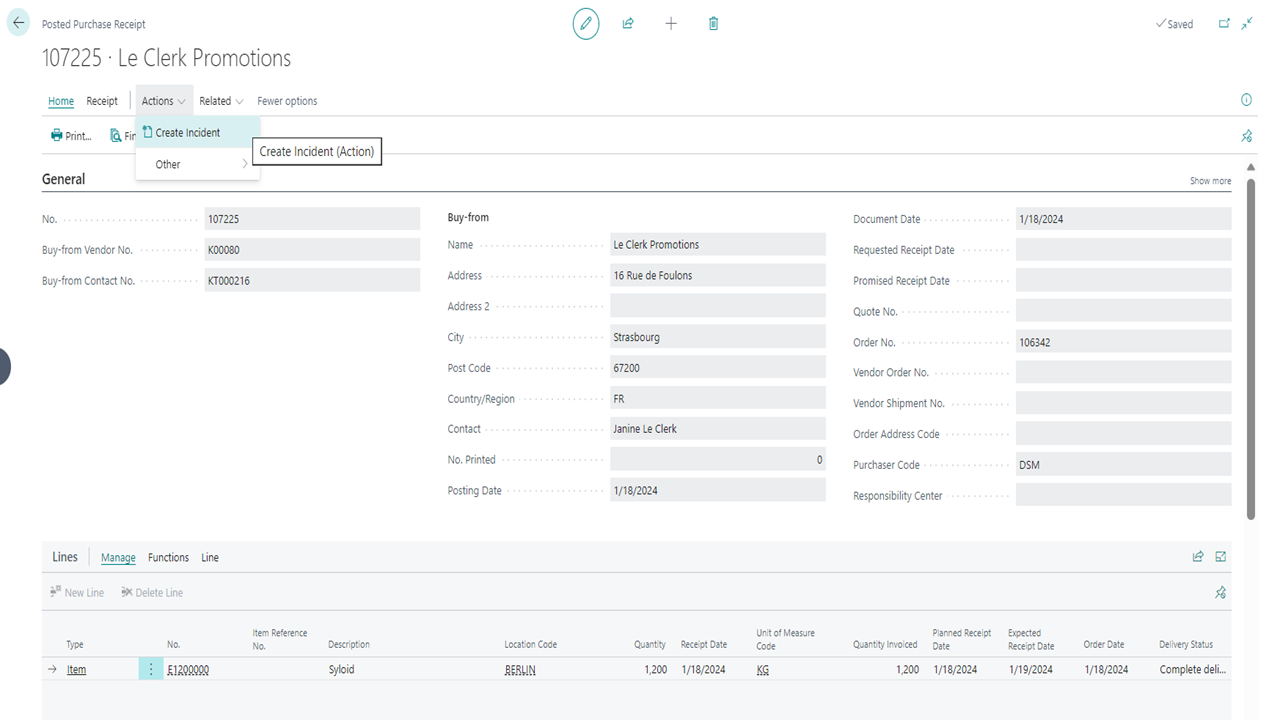

Create incidents from documents

Define incident types & error codes

User-specific permission sets

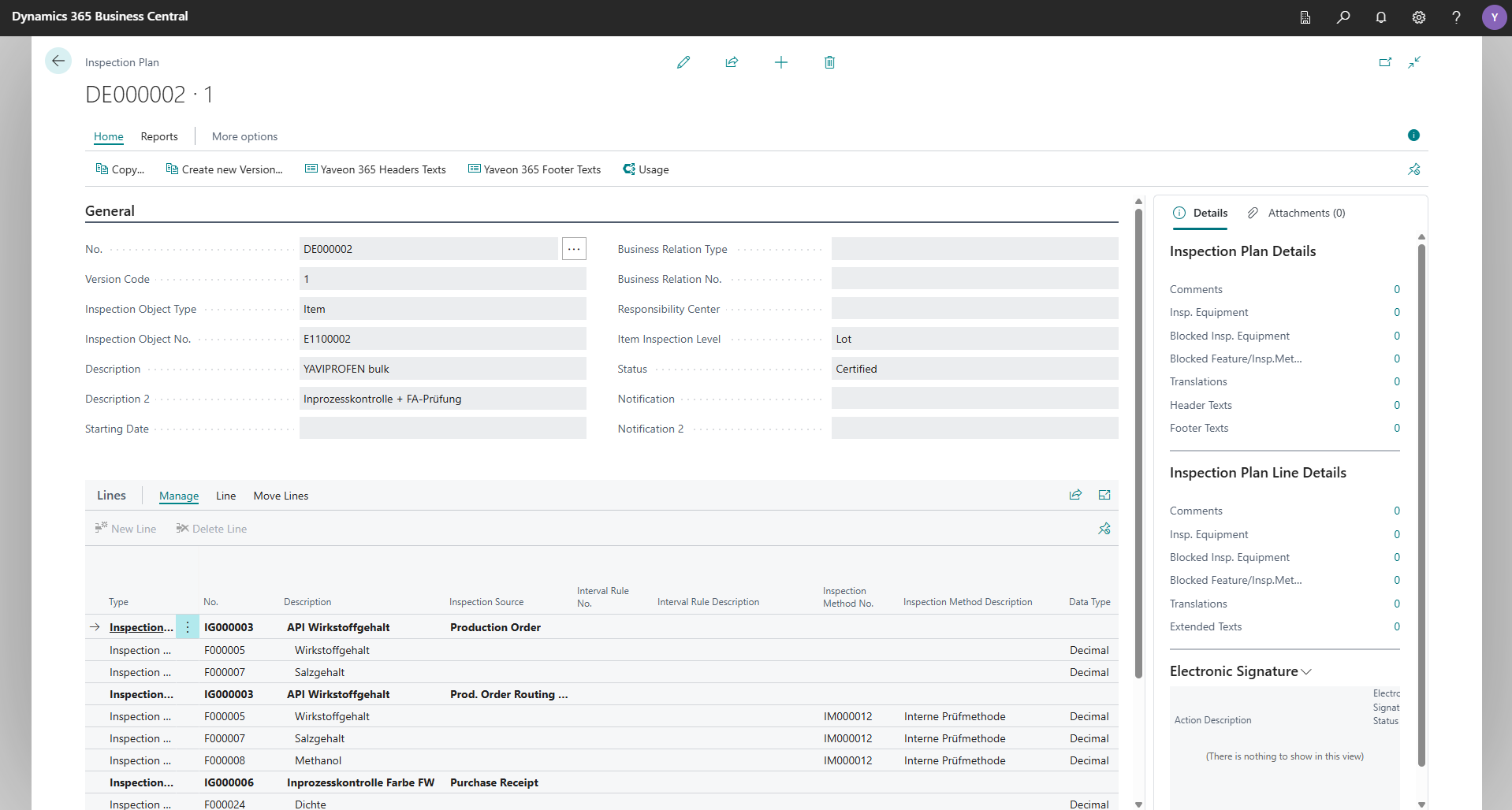

Electronic signatures according to FDA 21 CFR Part 11

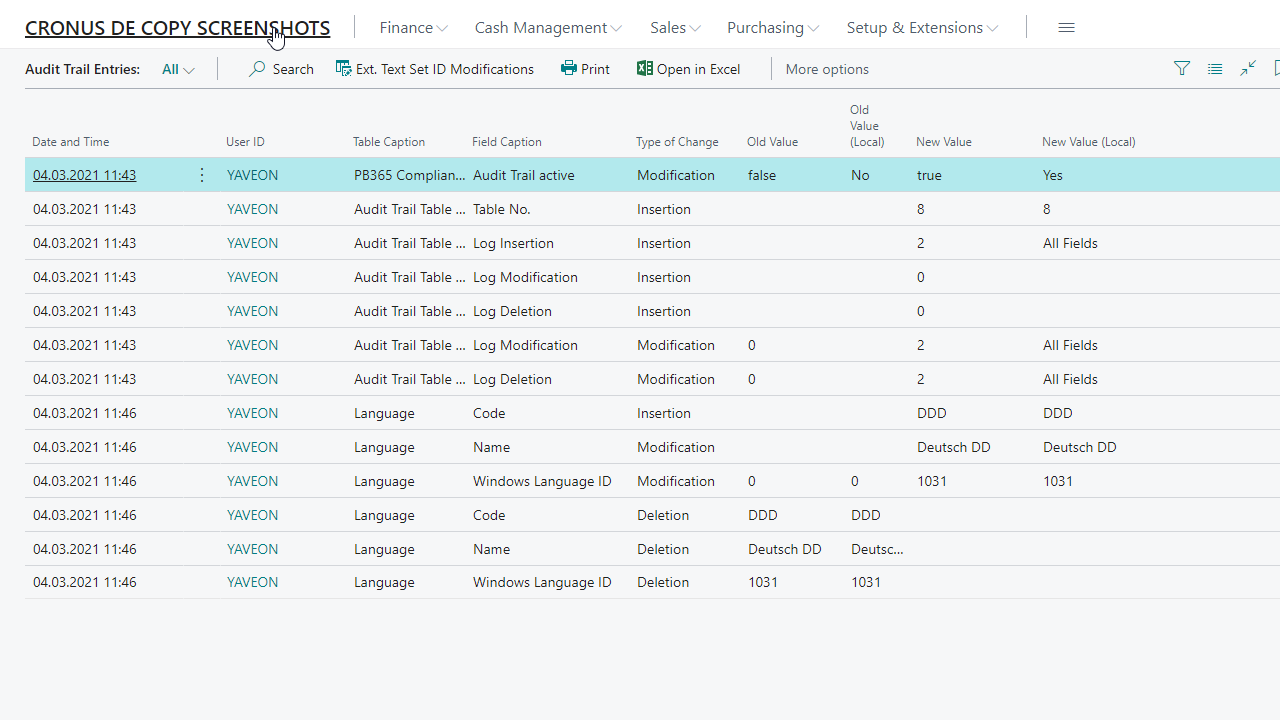

Traceability via audit trail

Field security by user role

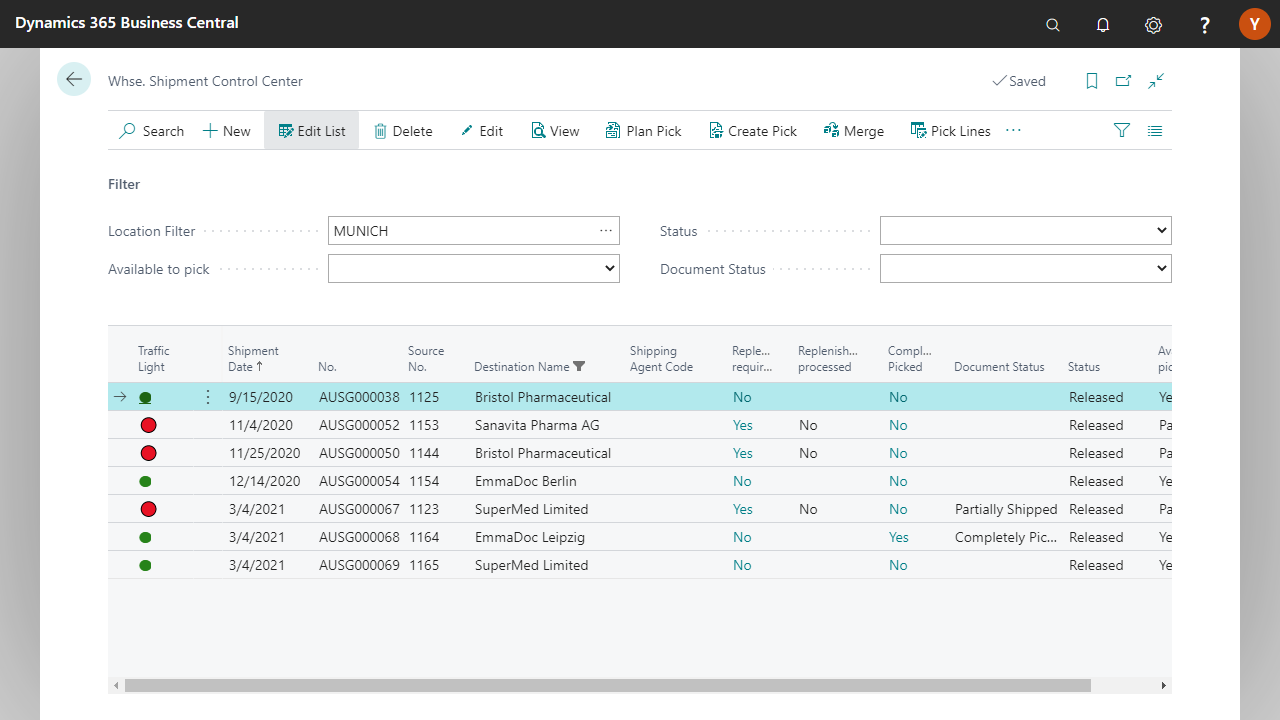

Warehouse receiving & transfer

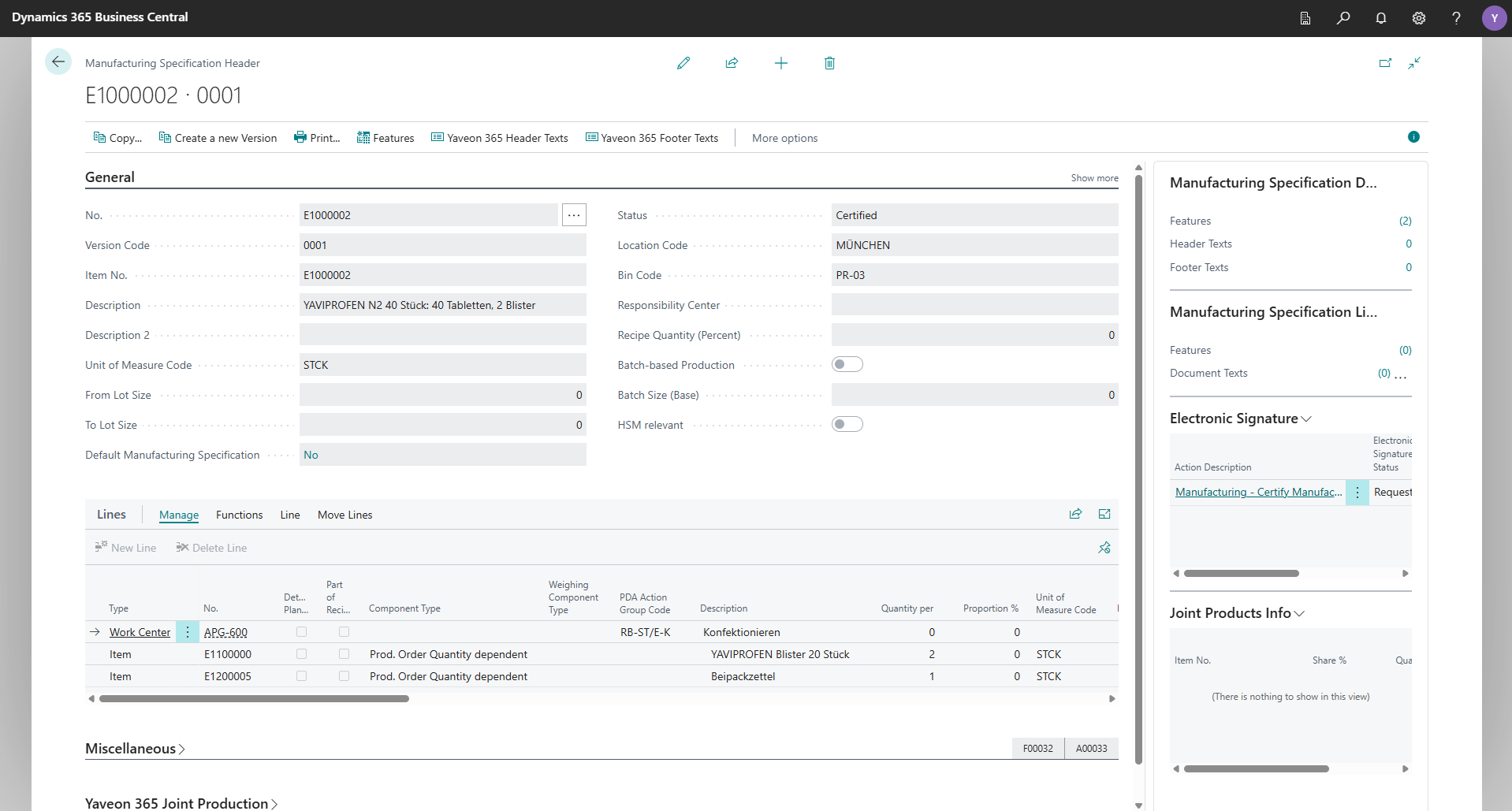

Consumption & actual reporting in production

UDI & serial number collection

Order picking with packaging structure

Master data & inspection methods

Automatic permissions

Approval processes & inspection orders

Audit-proof documentation

FEFO strategies & temperature zones

Warehouse receiving & pre shipment inspection, storage

Map quarantine and inspection warehouses

Communication via EDI

Create manufacturing instructions

Batch inheritance & feature calculation

Consumption posting according to FIFO/FEFO

Integration with QA and technology

Our ERP for medical devices meets the industry's high demands, including strict compliance with MDR and FDA regulations. GMP-compliant processes, audit trails, and lot tracking ensure transparent operations. Specific requirements such as comprehensive documentation are addressed and supported by our validation consulting. Modules like formulation and production scheduling optimize workflows and ensure compliance with legal requirements.

Implementing a specialized ERP software for medical devices offers numerous benefits that cater to industry requirements. It ensures regulatory compliance and supports comprehensive documentation and traceability of production and quality control processes, which are crucial for audits and certifications. Additionally, the ERP solution optimizes production and resource planning through real-time data analysis, enabling efficient raw material use and preventing supply shortages. Transparency at every step of production minimizes errors and ensures product quality.

An ERP software aids in the production of medical devices by streamlining production scheduling, resource allocation, and inventory management. It reduces bottlenecks, ensures compliance with regulatory requirements, and facilitates the automation of production processes. This not only enhances efficiency but also improves traceability and quality assurance, which are critical in the manufacturing of medical devices.

The cost of implementing and maintaining an ERP software depends on factors such as the size of your medical device company, the chosen solution, the need for customization, and the required features. The expenses include initial costs for implementation and ongoing costs for updates, support, and training.

In addition to our comprehensive online help, various training videos are available to make it as easy as possible for users to get started with the new medical device software.

Together with Microsoft, we continuously deliver new updates to ensure our software remains cutting-edge and meets your exact requirements. Our goal is to provide solutions that not only adhere to current standards but are also forward-thinking and tailored to the specific needs of the medical device industry.

Cost control in the medical device industry – Beitrag öffnen

Cost control in the medical device industry – Beitrag öffnen

How ERP systems in the medical device industry reduce costs through real-time monitoring and process optimization.

ERP compliance in the medical device industry – Beitrag öffnen

ERP compliance in the medical device industry – Beitrag öffnen

For SMEs in the medical device sector, ERP compliance is mandatory. Learn how to implement the regulations.

Validation-ready ERP for medical device companies – Beitrag öffnen

Validation-ready ERP for medical device companies – Beitrag öffnen

Learn how ERP systems meet GxP requirements with audit trails, documentation, and built-in compliance.