FEFO is a stock management strategy to ensure that products with the earliest expiry date are sold first.

With quality assurance, companies ensure that the quality of their products and services remains consistently high.

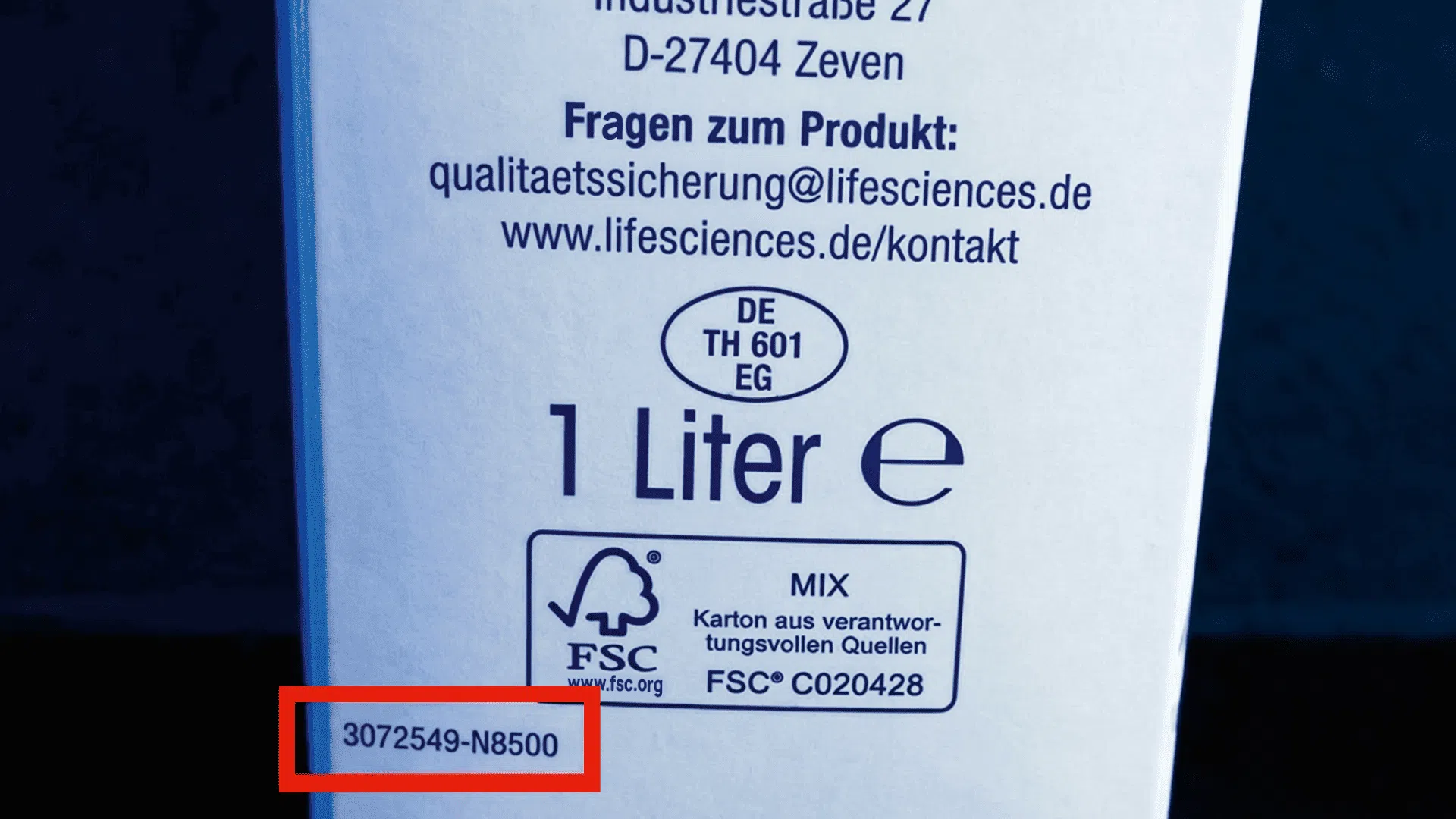

Batch management optimizes item-specific storage and tracking of goods using a unique lot number.

Supplier relationship management is the systematic relationship management between a company and its suppliers.

Quality control ensures products meet defined standards by checking, measuring, and correcting deviations.

An ERP system is a software solution that facilitates a company's resource planning and combines operational data.

A batch number is assigned to identify an entire batch and is usually printed directly on the product itself.

Joint production is a manufacturing process in which, alongside the main product, at least one additional product is generated.

Cloud ERP refers to an ERP system based on cloud technology. Companies access the system directly via internet.

How warehouse receiving links incoming goods to materials management, logistics, and financial accounting.

By definition, order picking is the process of compiling items and goods to fulfill customer or production orders.

How a practical checklist streamlines warehouse receiving and reveals digitalization potential.

Hazardous substance management covers all measures for the safe handling of hazardous substances

Incoming goods inspection is used to check incoming goods to ensure they meet quality requirements.

How a warehouse management system streamlines warehouse workflows and boosts supply chain efficiency.

First In - First Out (FIFO) is a warehouse strategy in which items that arrive in the warehouse first are also used first.

Lot tracking allows to trace products and back to producers and ingredients throughout the supply chain.

EDI stands for Electronic Data Interchange and refers to the standardized, electronic exchange of documents.

Pre-shipment inspection ensures that customers receive the right product – in the correct quantity and quality.