Optimize warehouse receiving with a checklist: Check processes, identify digitization potential and increase efficiency in warehouse & logistics.

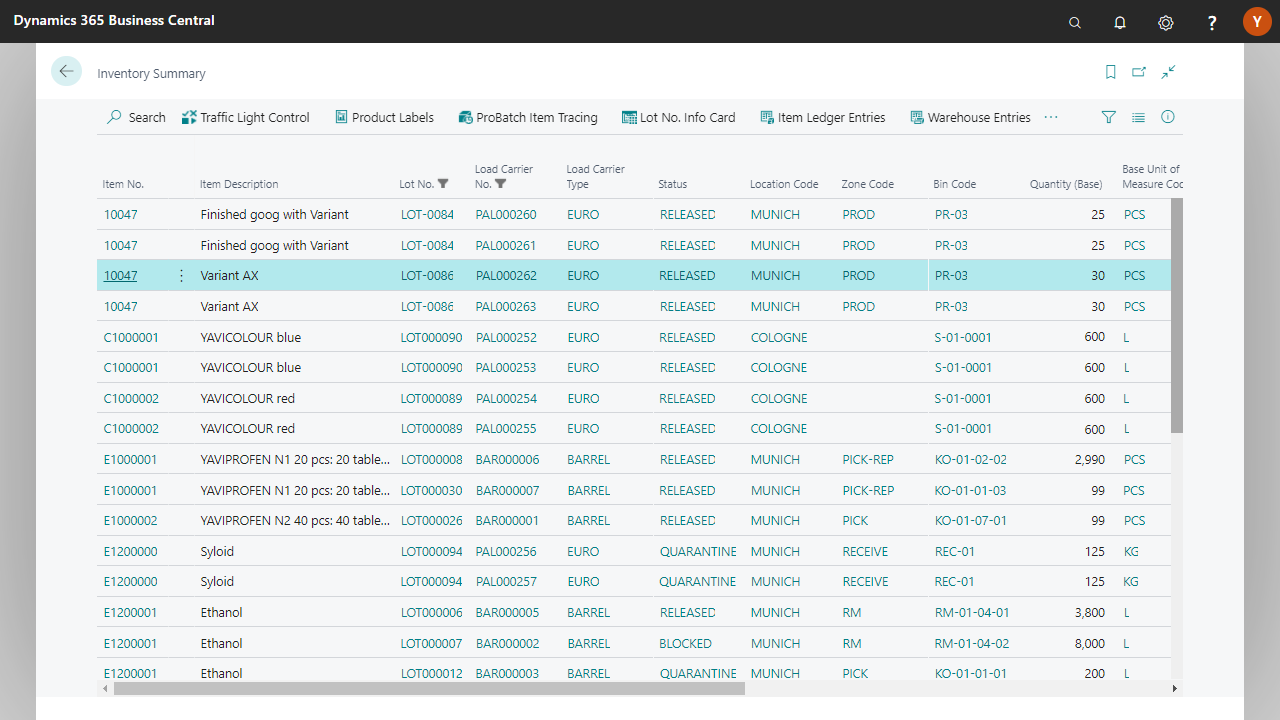

Current: Real-time inventory management with batch and serial numbers

Efficient: Manage load carriers and storage locations

Integrated: advanced warehousing and order picking strategy

More than 850 companies worldwide rely on Yaveon

Warehouse location management and optimization of warehouse structure

Fixed and dynamic storage locations

Storage zones and quarantine warehouse

ABC classification

Summary of a shipping unit possible

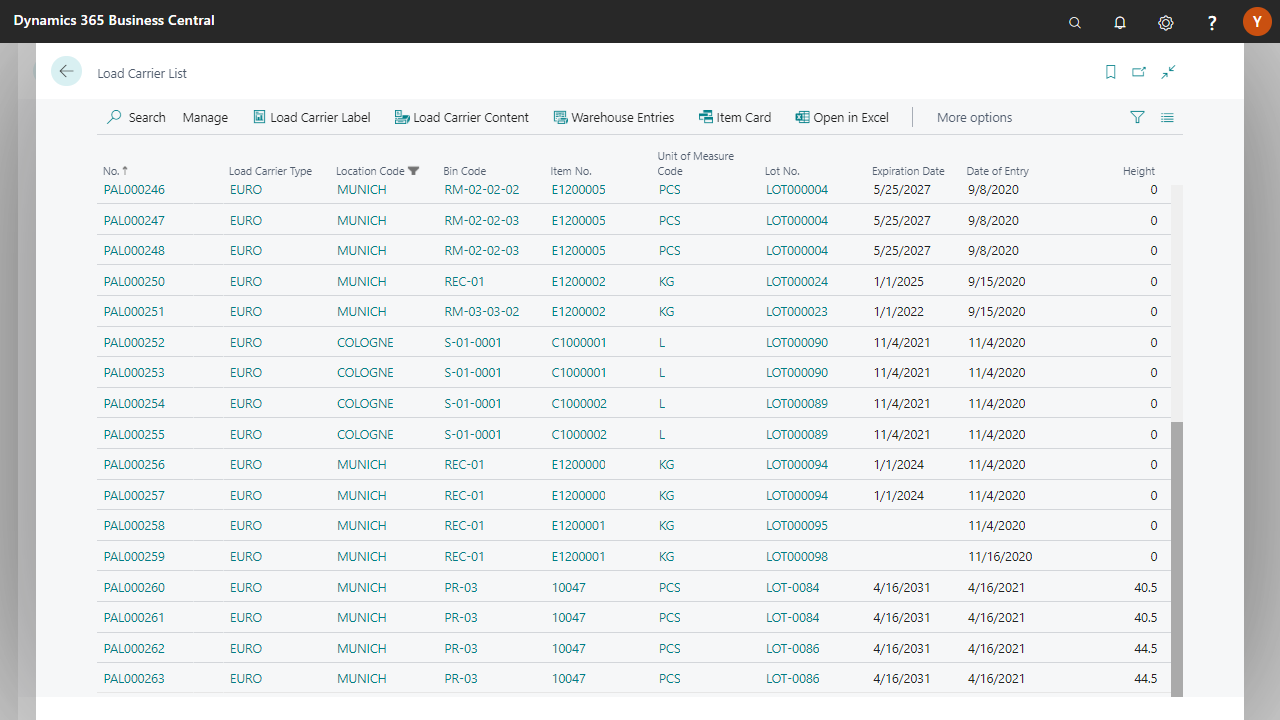

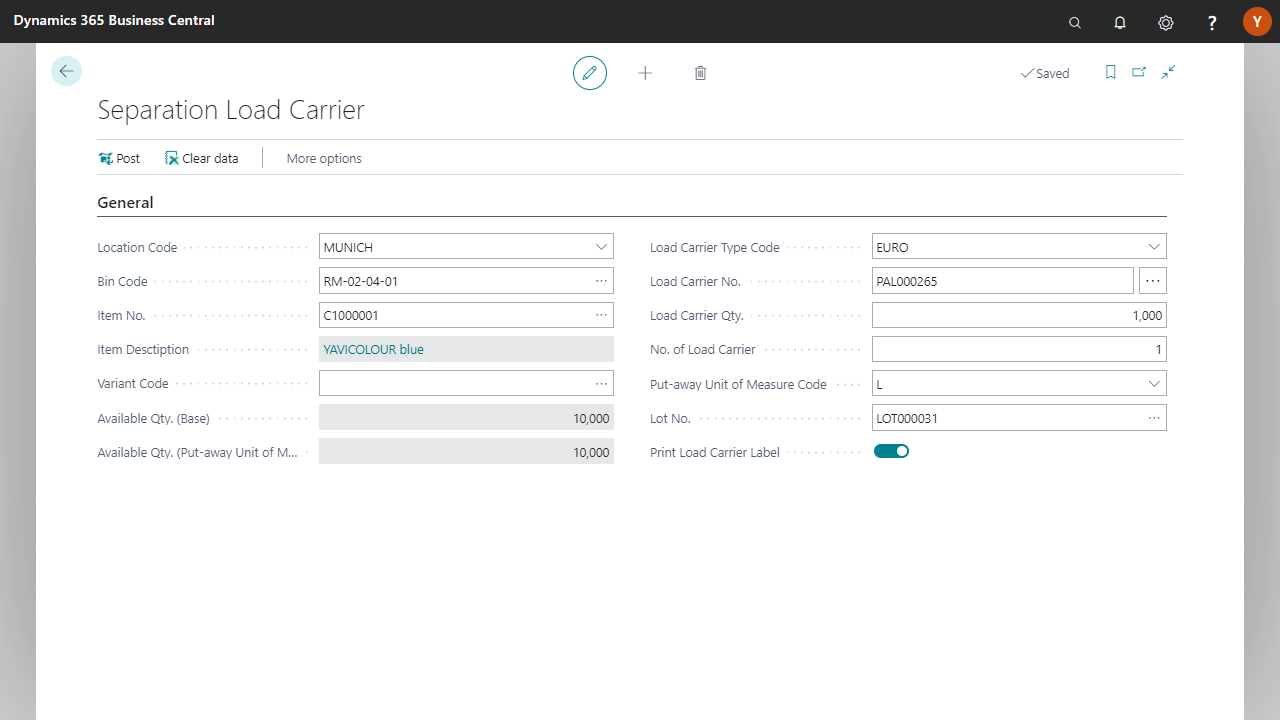

Consistent use of load carriers in the system

Automatic height calculation based on master data

Simplified warehouse movements for load carrier handling

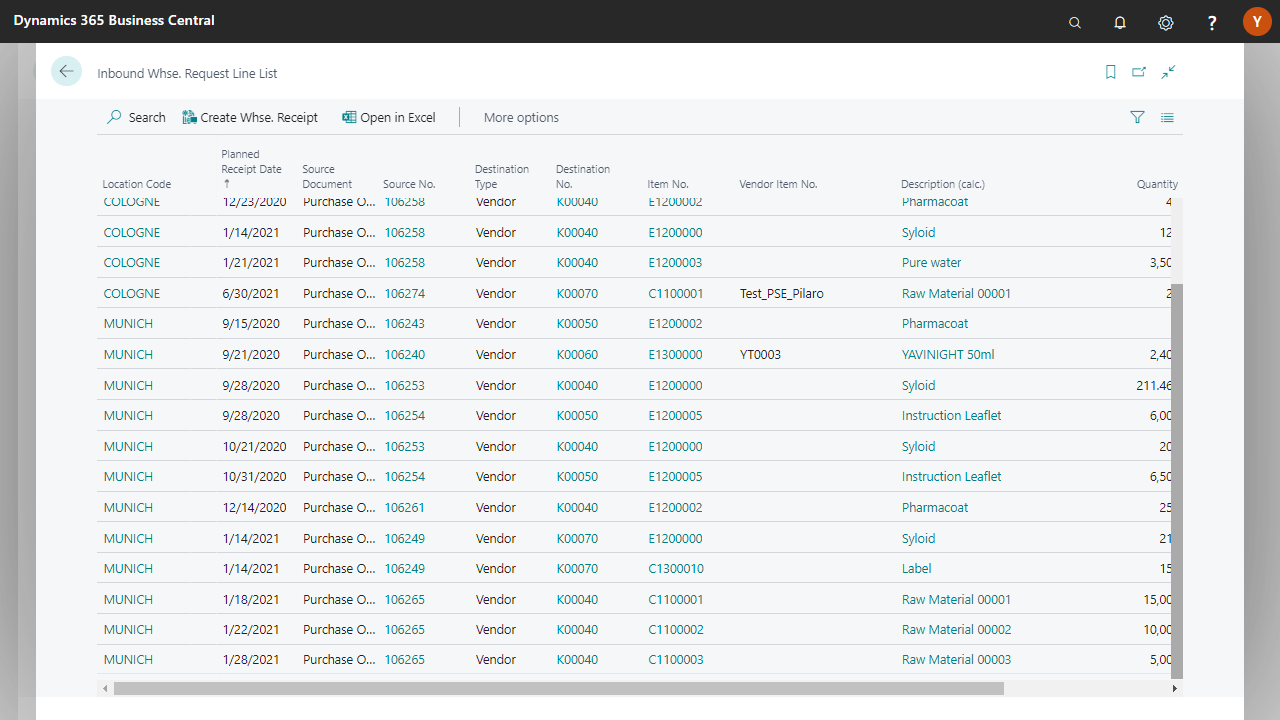

Inspection steps upon receipt in combination with the Yaveon QA App

Direct bookings into tanks or fixed storage locations

Automatic postings with shipping notifications using the EDI app

Isolation of inventory on load carriers

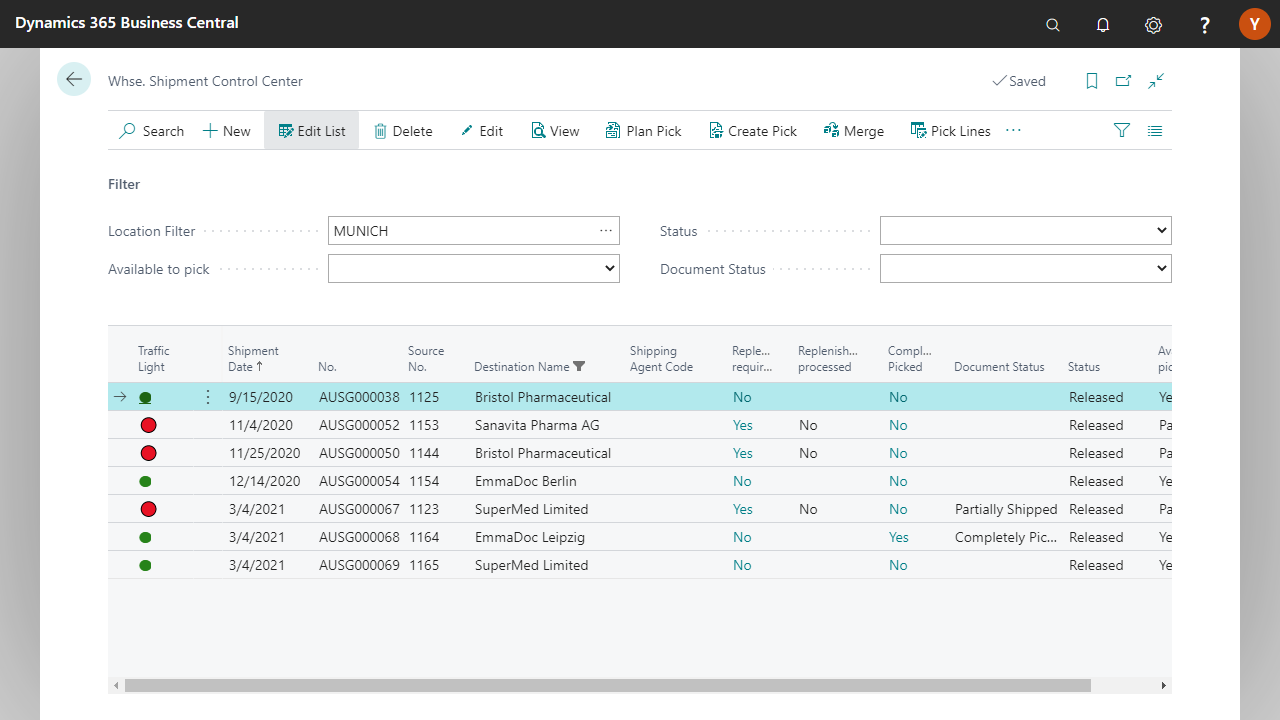

Outbound logistics with shipment logic

Assignment of delivery notes and label printing

Creating shipping units

Overview of pre shipment status and order picking

In real time with batches and serial numbers

Item tracing

Minimum and safety stock levels

Automatic postings for incoming and outgoing goods

Compiling goods for shipment

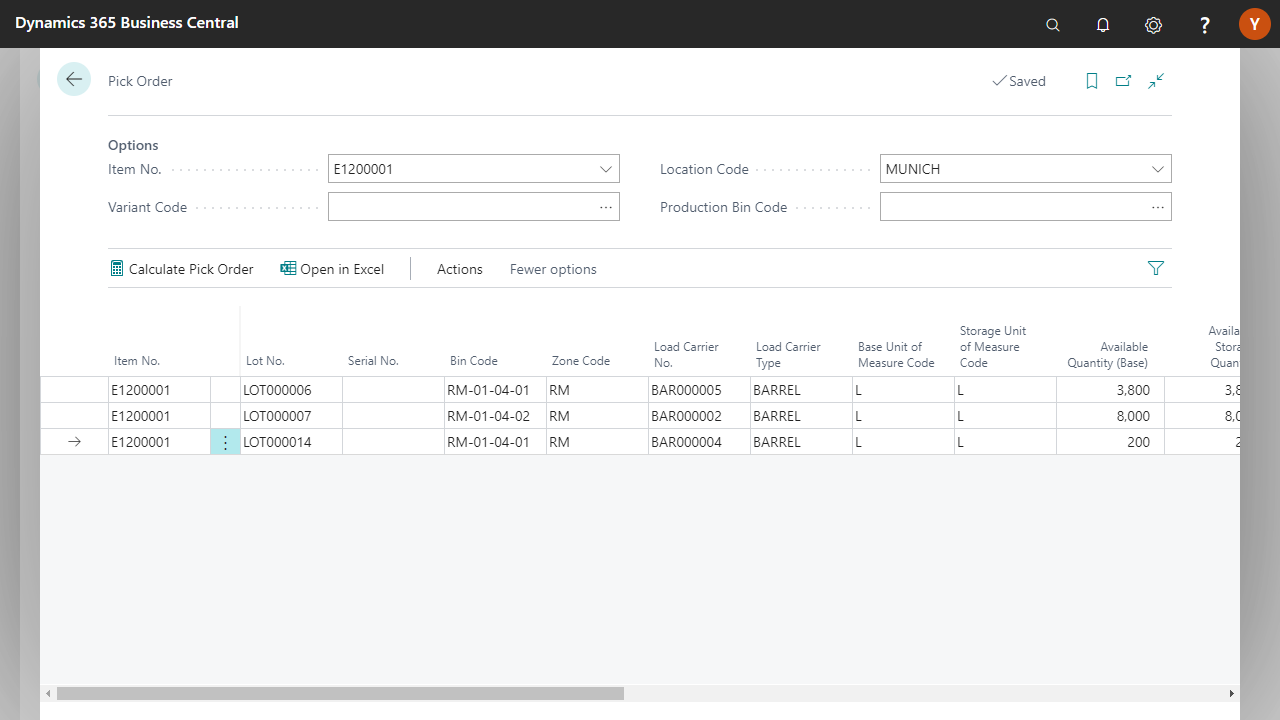

Pick order for precise inventory selection

Consideration of inventory rounding & drop-off locations

Processing possible via mobile devices

Consolidation of multiple orders for material supply

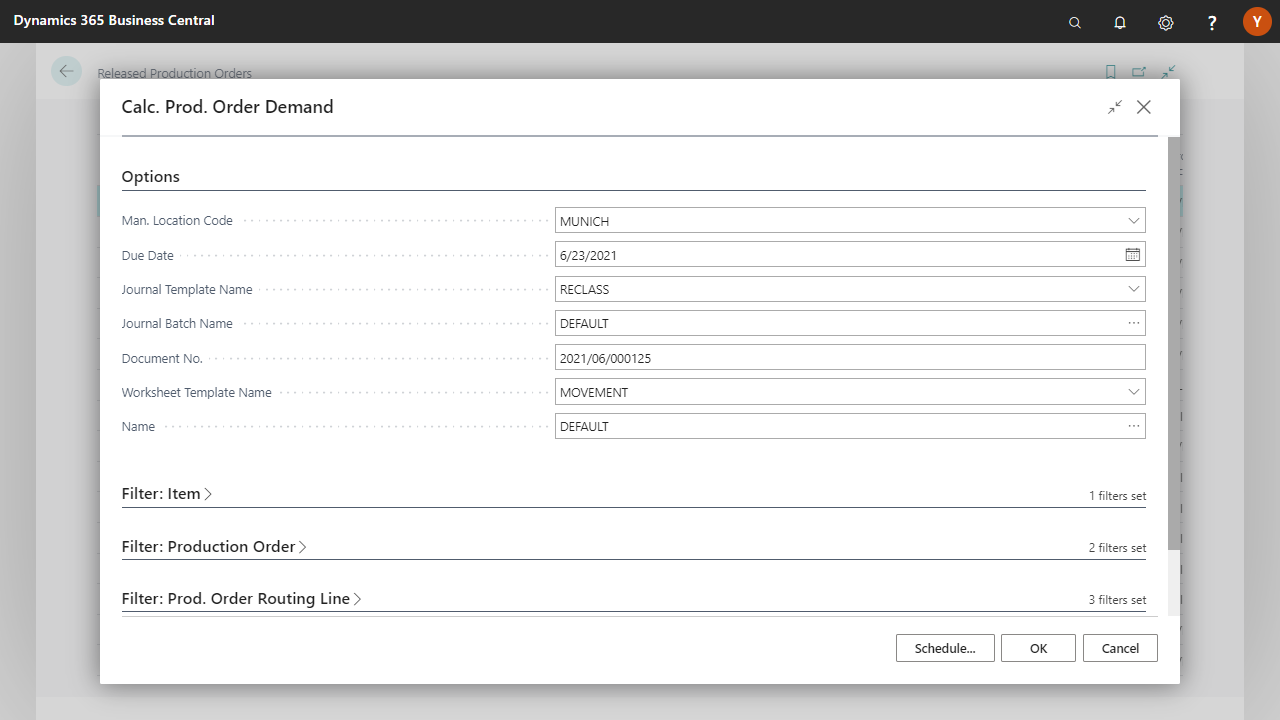

Production supply for optimal production support

Calculate production requirements for auxiliary and operating materials

Inventory rounding, over-picking, overuse

Yaveon 365 Warehouse Management allows for the management of fixed and dynamic storage locations and slots, as well as structuring through warehouse zones and quarantine storage. This optimizes the utilization of warehouse space, shortens access paths, and reduces search times. To find the optimal storage locations for goods, factors such as weight, height, and item features can be considered. Using a storage template, you can define how the system identifies the right location for your items.

Inventories are automatically updated with every posting, including batches and serial numbers. Minimum and reorder levels can be recorded, ensuring a precise, traceable, and up-to-date inventory overview is always available.

The app facilitates the systematic assortment of goods, managed by priorities and zones. Through the pick order, you can reserve stock in advance of order picking. Over- and under-picking within established tolerances are accepted, accounting for inventory rounding to whole load carriers or packaging units. If insufficient stock is available in the picking area, the system can automatically trigger a replenishment.

Yaveon 365 Warehouse Management provides features for planned and ongoing inventory with mobile data collection, real-time reconciliation, and automated posting. This reduces the effort required for inventories and significantly increases the accuracy of the results.

In many cases, yes. The app integrates seamlessly with Business Central and is designed for integration.

The app supports connecting multiple warehouse locations/sites. External warehouses can also be managed in an organized manner and fully integrated into processes such as warehouse receiving and shipment, order picking, or inventory. External warehouses managed by a logistics provider can be linked using the 3PL app.

Successfully optimizing warehouse receiving – Beitrag öffnen

Successfully optimizing warehouse receiving – Beitrag öffnen

Optimize warehouse receiving with a checklist: Check processes, identify digitization potential and increase efficiency in warehouse & logistics.

7 measures how to reduce your storage costs – Beitrag öffnen

7 measures how to reduce your storage costs – Beitrag öffnen

What does it mean to reduce storage costs? What measures help and how does software provide support? We'll show you.

The digital potential of the process industry – Beitrag öffnen

The digital potential of the process industry – Beitrag öffnen

We show you how the process industry can discover and unleash its greatest digital potential.