Schulz supports its international growth with an ERP solution tailored to the company’s specific requirements.

Centrally manage: hazardous substances data & safety data sheets

Transport safely: GHS-compliant labeling & transport marking

Act in compliance: Adherence to legal regulations through compliance

More than 850 companies worldwide rely on Yaveon

Storage & exchange of information from the HSM system

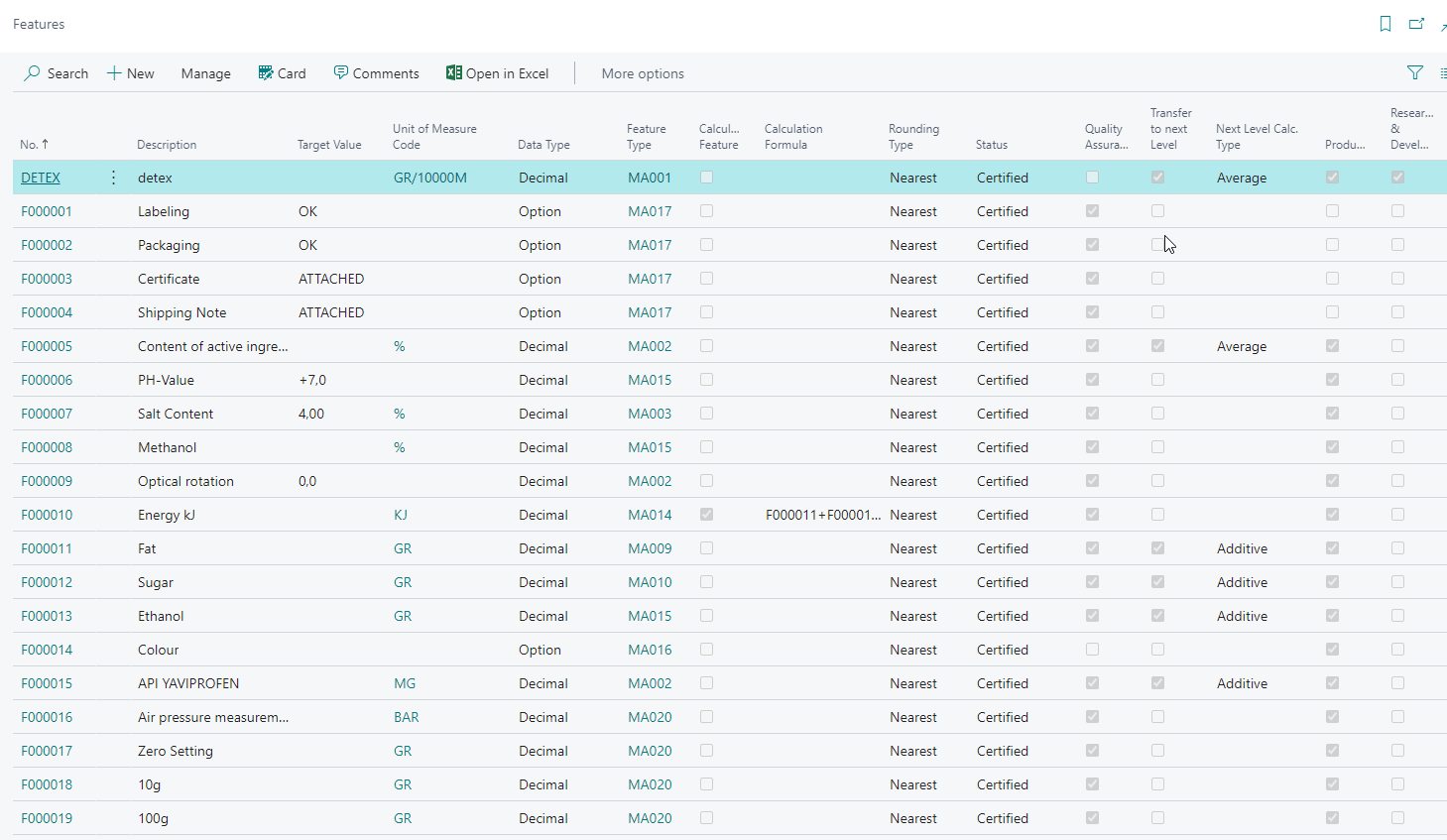

Dynamic interface extension with new features

Unit codes, option values, and more with item features

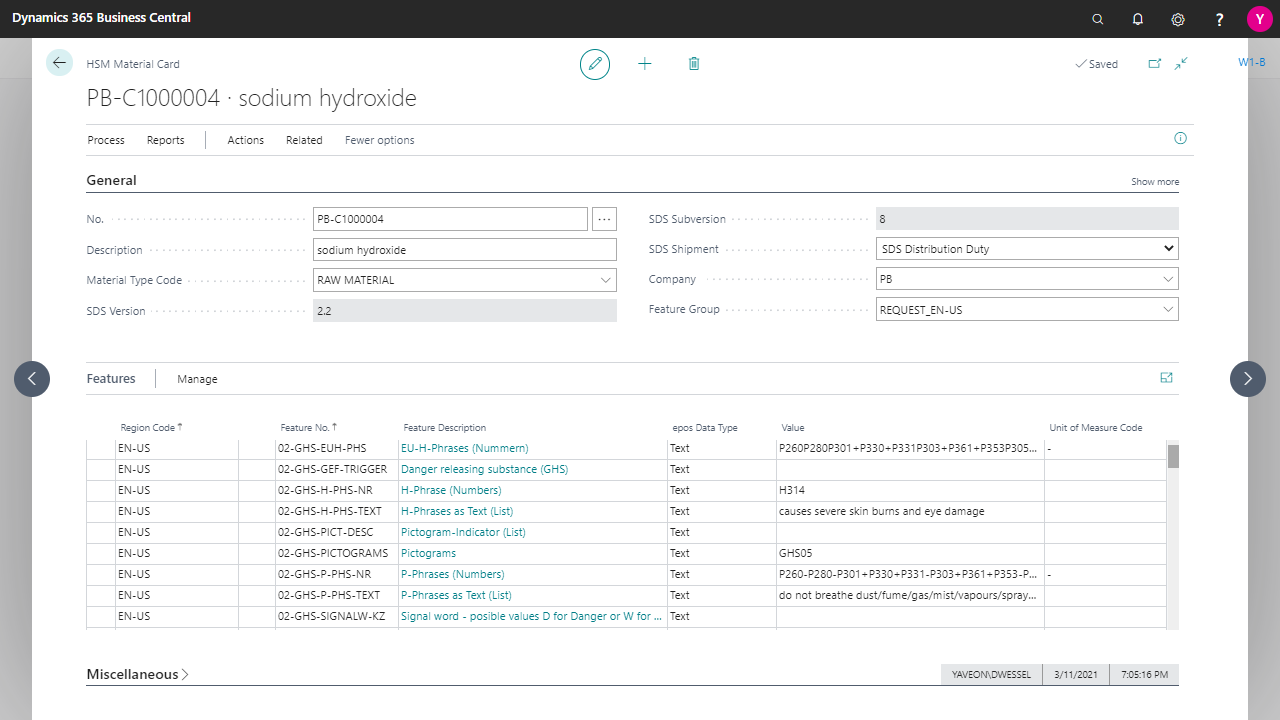

Creation of the HSM material based on the item

Transfer of the HSM substances to the HSM system

Retrieve feature values

Creating synonyms to represent distributors

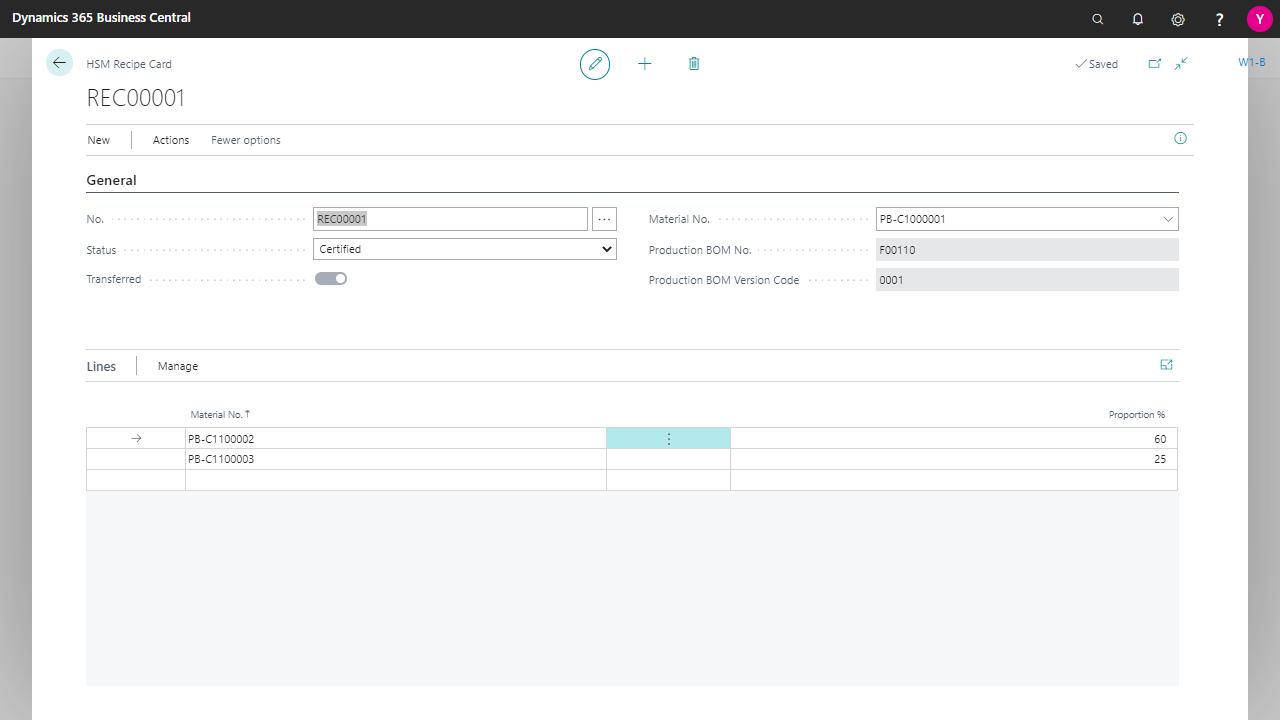

Specification of components for a product to be manufactured

Creating HSM recipes

Manufacturing guidelines

Data entry in the manufacturing instructions

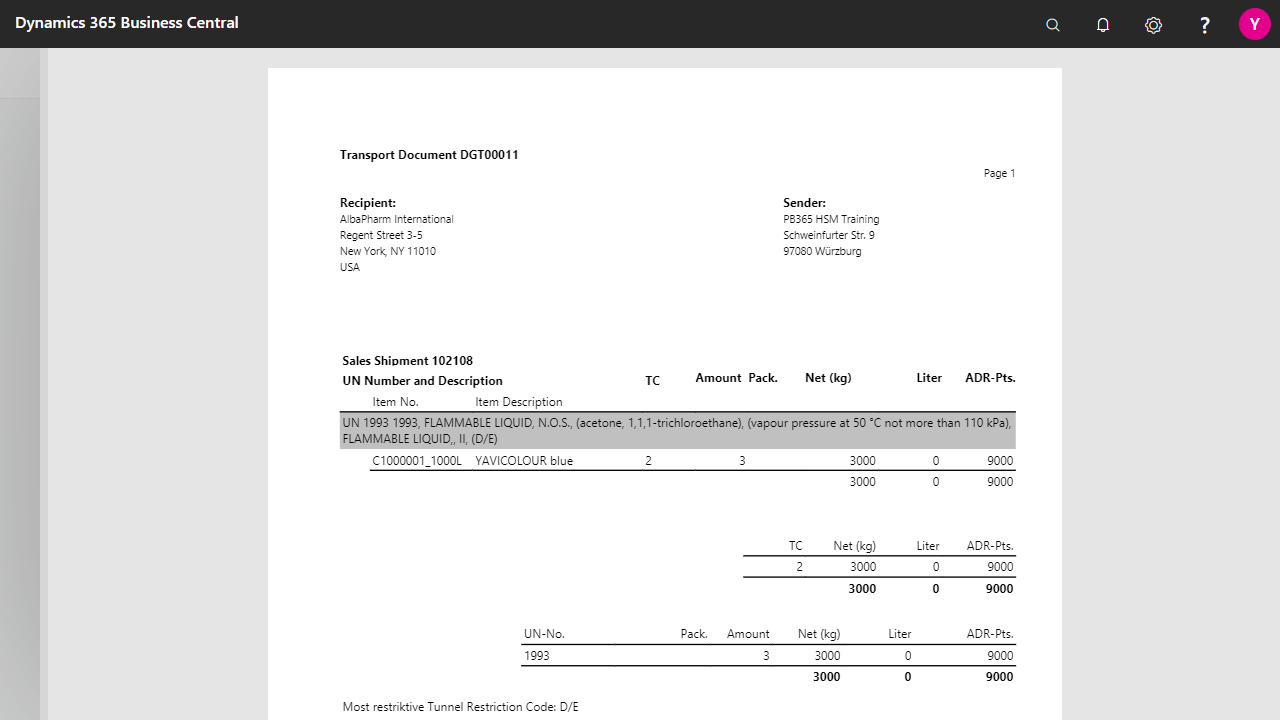

Create necessary accompanying documents

Sales shipment, transfer order, or purchase return as a basis

Creation of HSM shipment items

Issuance of transport documents in various languages

Access to safety data sheets

Automatic dispatch via batch run

Creating document recipients

GHS-compliant and automated labeling

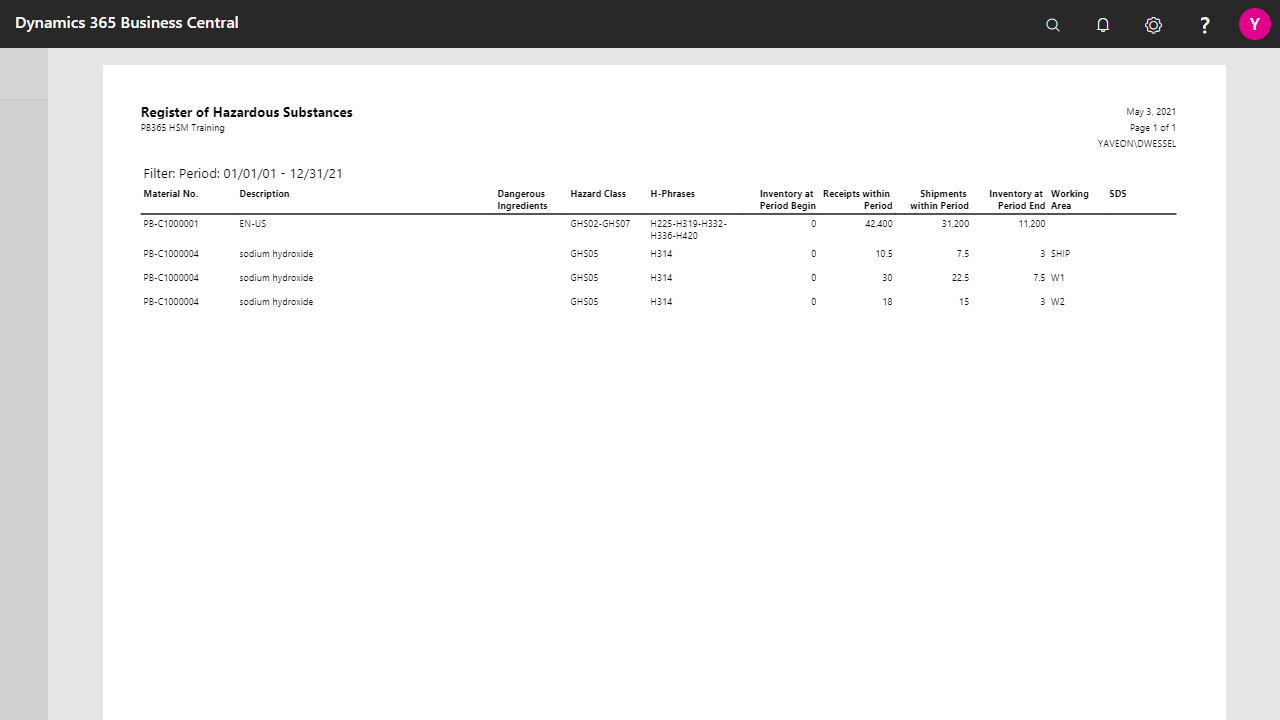

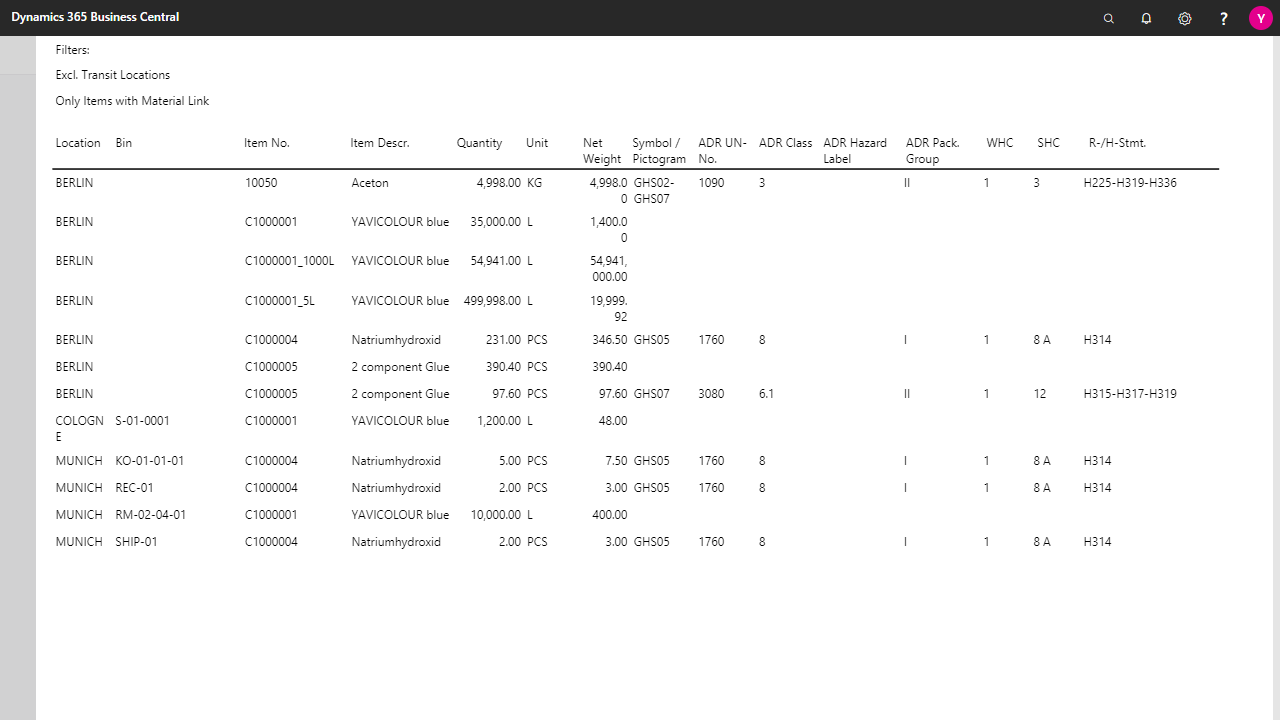

Overview of all hazardous materials in stock

Filter by storage location, specific features & materials

Breakdown by work area

The app allows for the management of safety data sheets directly within the ERP. Safety data sheets can be automatically sent from one of the two connected HSM systems (Epos or Chemdox) through batch processing, assigned to specific customers, and accessed at any time.

The app is specifically designed for integration with the chemical management systems epos and Chemdox. The integration is bidirectional, allowing you to reliably synchronize feature data, materials, recipes, and safety data sheets between the systems.

Yes, the app generates relevant transportation documents.

Integration with Microsoft Dynamics 365 Business Central enables seamless, media-disruption-free processes: master data, formulations, and material flows are directly linked to hazardous substances information. This significantly reduces maintenance efforts, eliminates duplicate work, and ensures all safety-relevant data is readily available across the system.

The app automatically captures and updates all relevant substances, compiling them in a digital hazardous substances register. Inventory can be filtered by storage location, hazardous substance features, or area of application and evaluated at any time.

Data exchange occurs through interfaces between the ERP and the hazardous substance management system. Companies can flexibly control whether data is transferred from the ERP to the HSM system, received from there, or synchronized in both directions.

Success story: Schulz Farben & Lacke – Beitrag öffnen

Success story: Schulz Farben & Lacke – Beitrag öffnen

Schulz supports its international growth with an ERP solution tailored to the company’s specific requirements.

Success story: Epple Druckfarben – Beitrag öffnen

Success story: Epple Druckfarben – Beitrag öffnen

Epple Druckfarben AG enhances efficiency and overcomes industry-specific challenges using Yaveon solutions.

ERP trends for 2026: what drives companies – Beitrag öffnen

ERP trends for 2026: what drives companies – Beitrag öffnen

ERP Trends 2026: AI, Cloud & ESG. What drives process manufacturing industry – and how it stays future-ready