We show you how the process industry can discover and unleash its greatest digital potential.

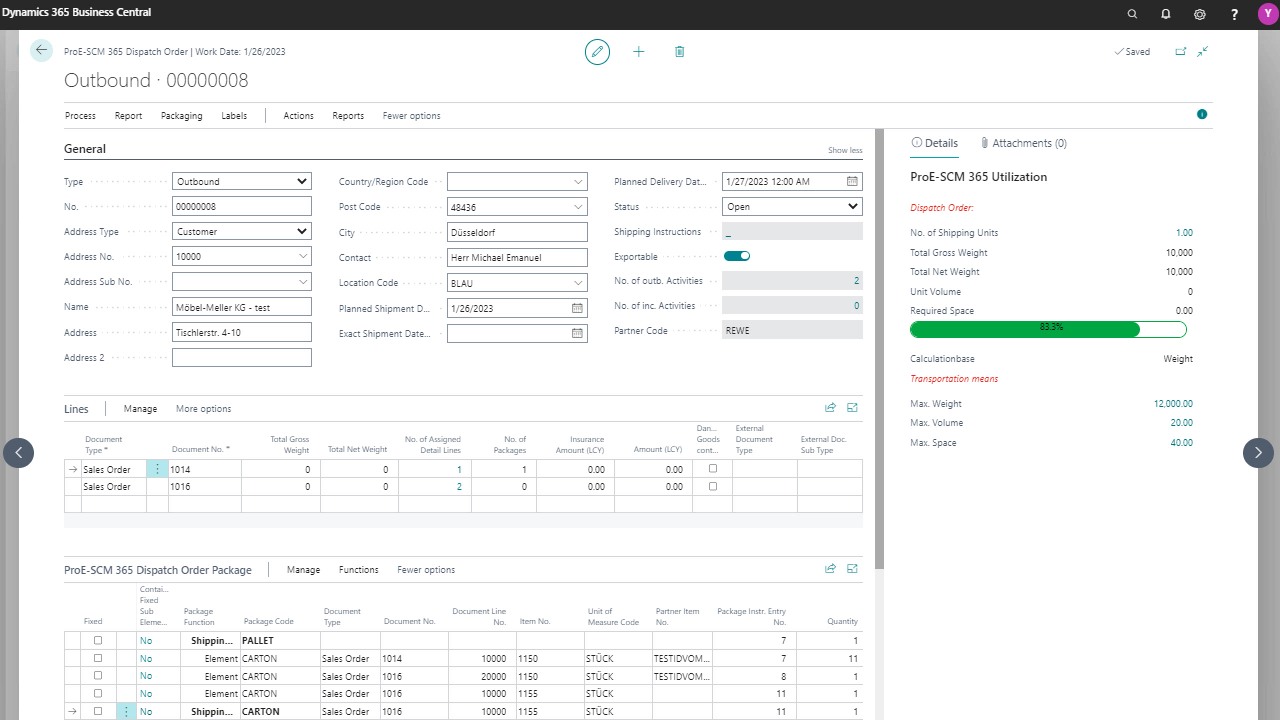

Central utilization: integration of third-party logistics services

View current data: Insights into inventory levels & movements

Seamlessly integrate: Integration with standard mappings in the ERP

More than 850 companies worldwide rely on Yaveon

Customer and supplier addresses

Notification of shipments and receipts

Shipment confirmations

Warehouse receiving confirmations

Multi-client warehouse management

Independently set up clients, reports & storage locations

Inventory tracking and returns management

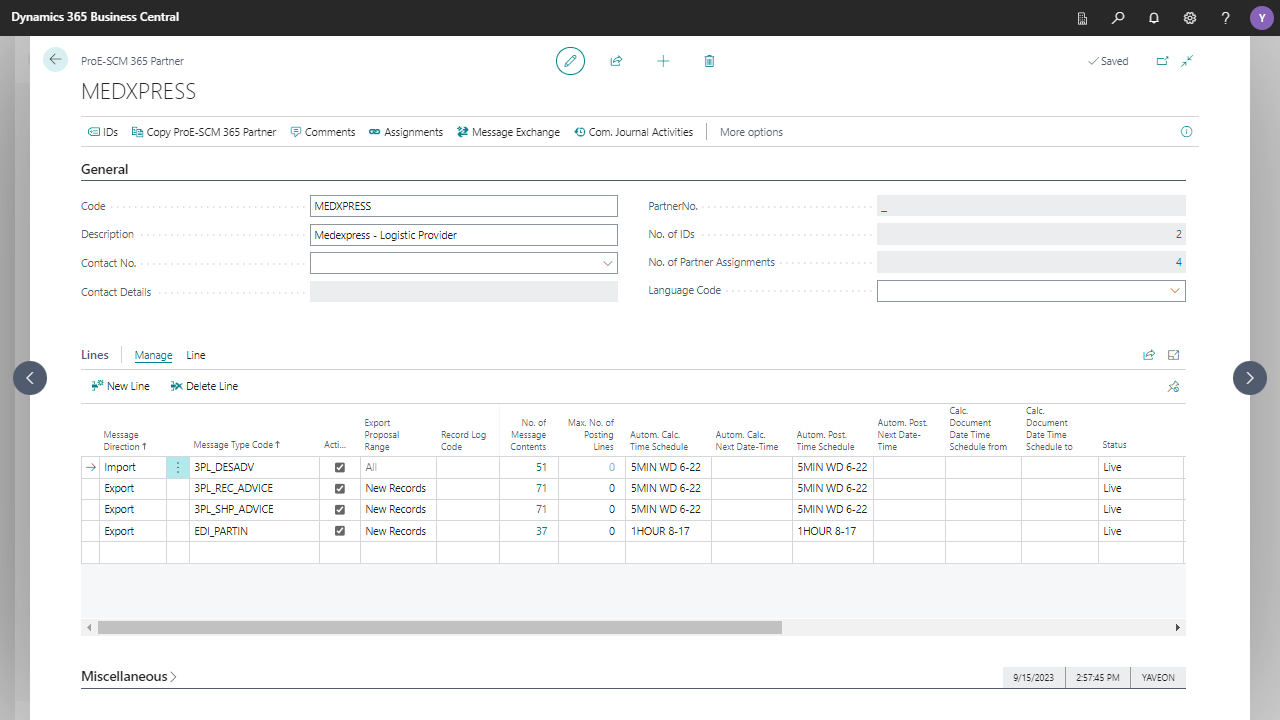

By configuring different partners in Yaveon 365 3PL Connect, multiple warehouses can be integrated. Each partner is linked to a distinct warehouse location. Custom settings can be made for each partner.

With EANCOM, a common standard for integration with external warehouses in the EDIFACT format is defined. Message types such as INSDES, DESADV, RECADV, INVRPT, PRICAT, and PARTIN are typically used for data transmission. If the external service provider does not support this standard, custom formats can also be configured.

The 3PL software enables the simultaneous management of multiple customer warehouses through multi-tenancy, separate warehouse structures, and customer-specific processes.

The app supports bidirectional exchange for warehouse receiving, shipments, inventory, transfers, and shipping information—fully integrated into your ERP processes—as well as the transfer of items and delivery addresses to the warehouse service provider.

Supported formats include EDIFACT, XML, CSV, JSON, and standard protocols like Azure File Share or Webservice, depending on coordination with the 3PL partner.

The digital potential of the process industry – Beitrag öffnen

The digital potential of the process industry – Beitrag öffnen

We show you how the process industry can discover and unleash its greatest digital potential.

Success story: Midas Pharma – Beitrag öffnen

Success story: Midas Pharma – Beitrag öffnen

Midas connects its warehouse directly to an external logistics provider and processes orders automatically with Yaveon ERP.

Success story: Hameln Pharma – Beitrag öffnen

Success story: Hameln Pharma – Beitrag öffnen

hameln pharma connects an external warehouse via a standard interface and saves time through automated processes.