We show you how the process industry can discover and unleash its greatest digital potential.

Fully integrated: no additional converter needed

Versatile use: scalable solution for tier-1 suppliers

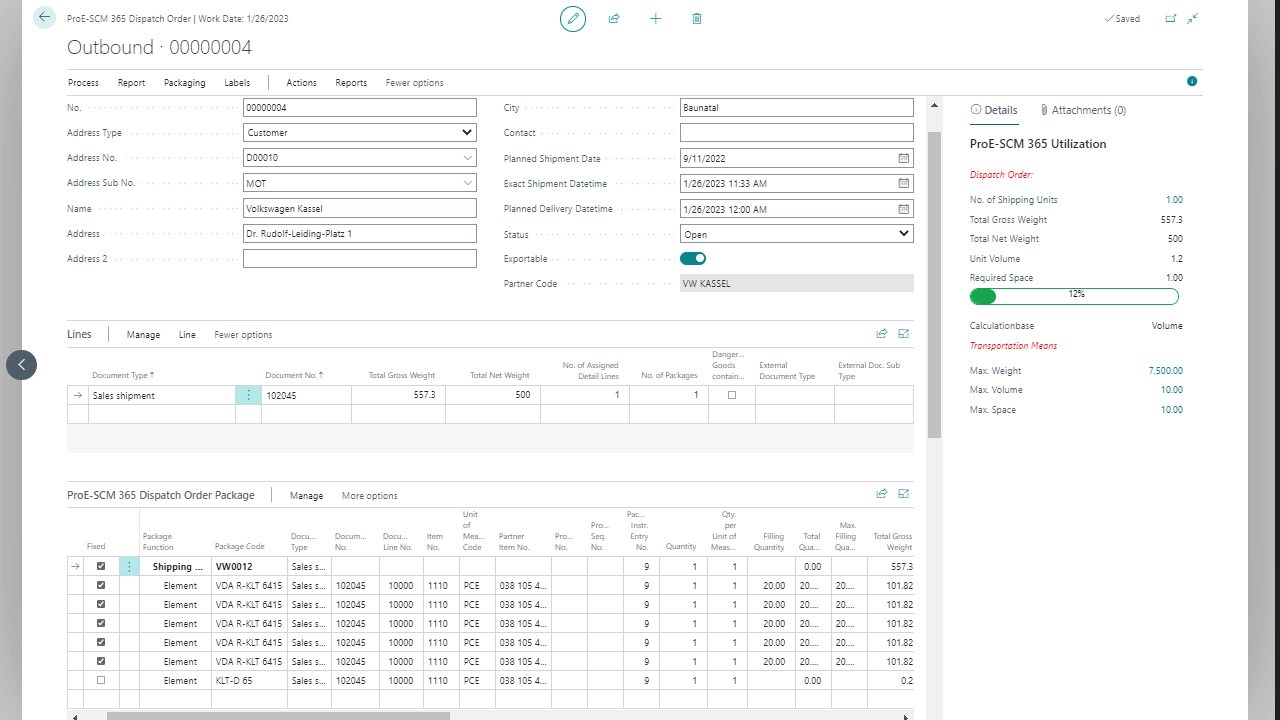

Currently viewing: Data processing for VDA messages

More than 850 companies worldwide rely on Yaveon

Supports VDA, EDIFACT, ODETTE, and ANSI X12 formats

Processes including DELFOR, DELINS, DELJIT, DESADV, INVOIC

Integration with OEM systems

Conversion of blanket and sales orders

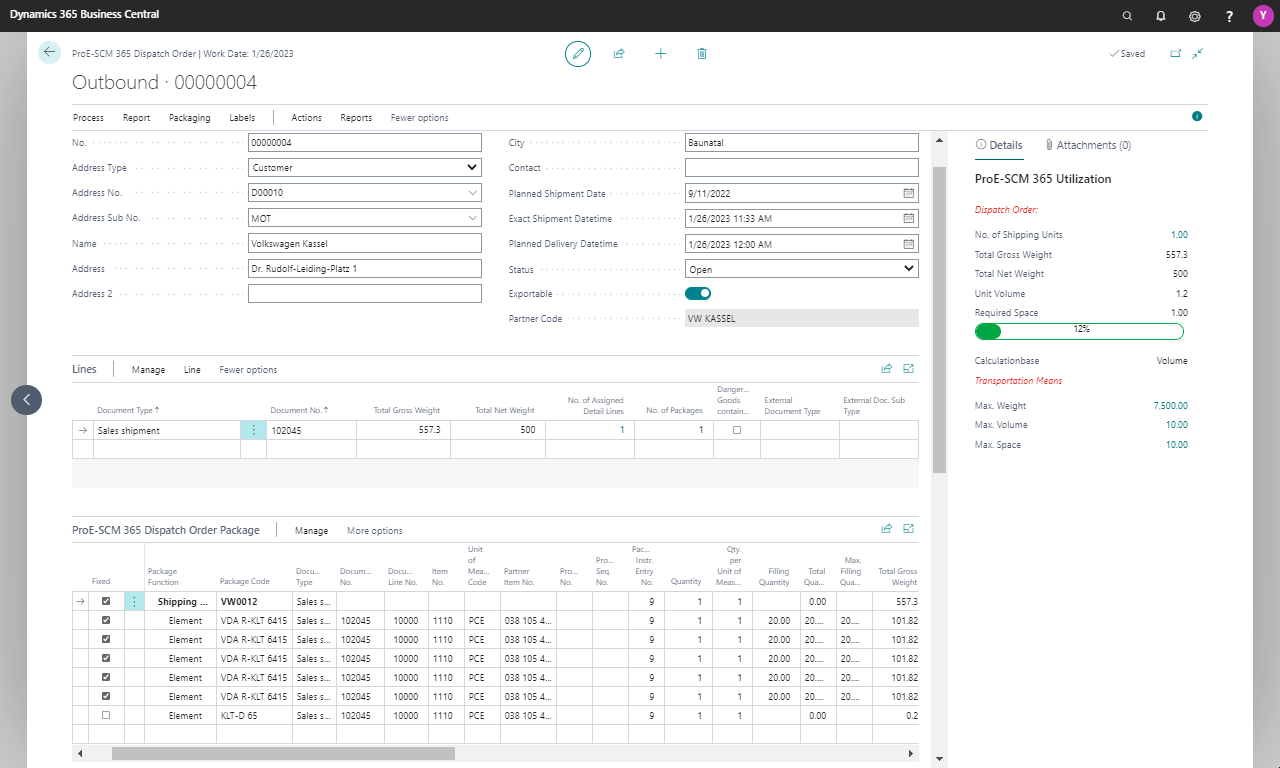

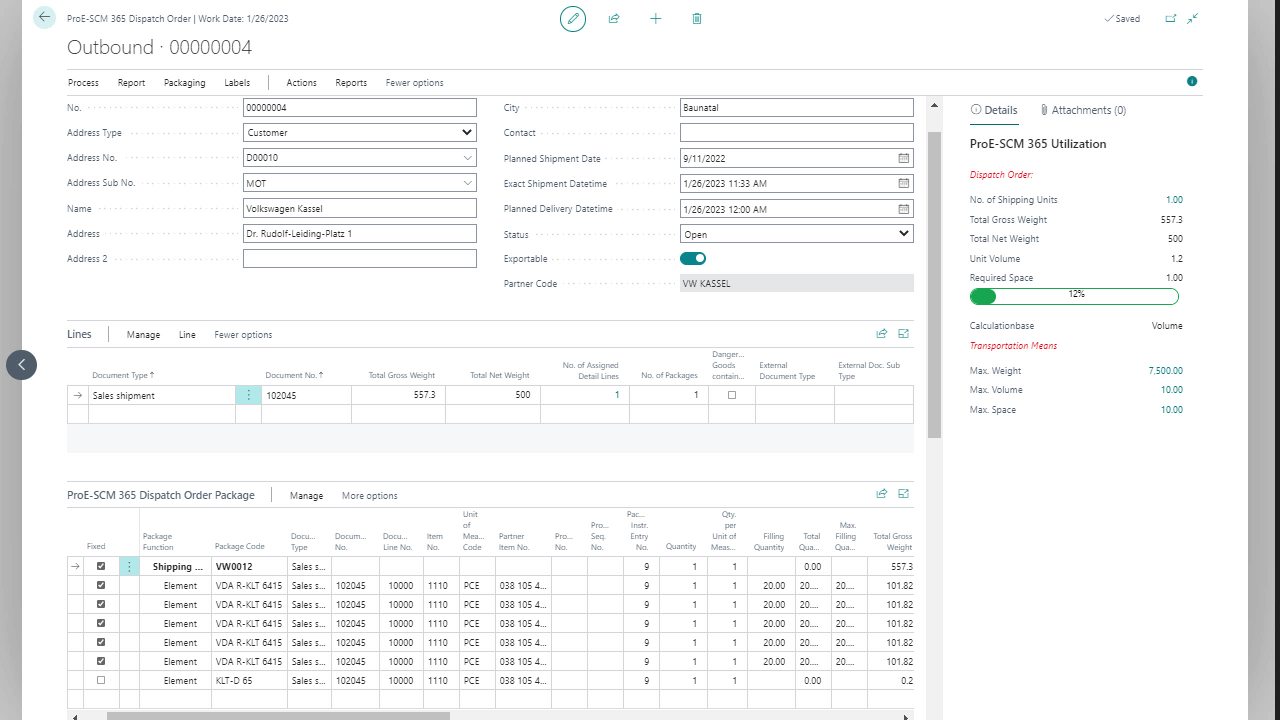

Initiating the shipment

Creating a sales or transfer order line

Delivery proposal as a central element of shipment planning

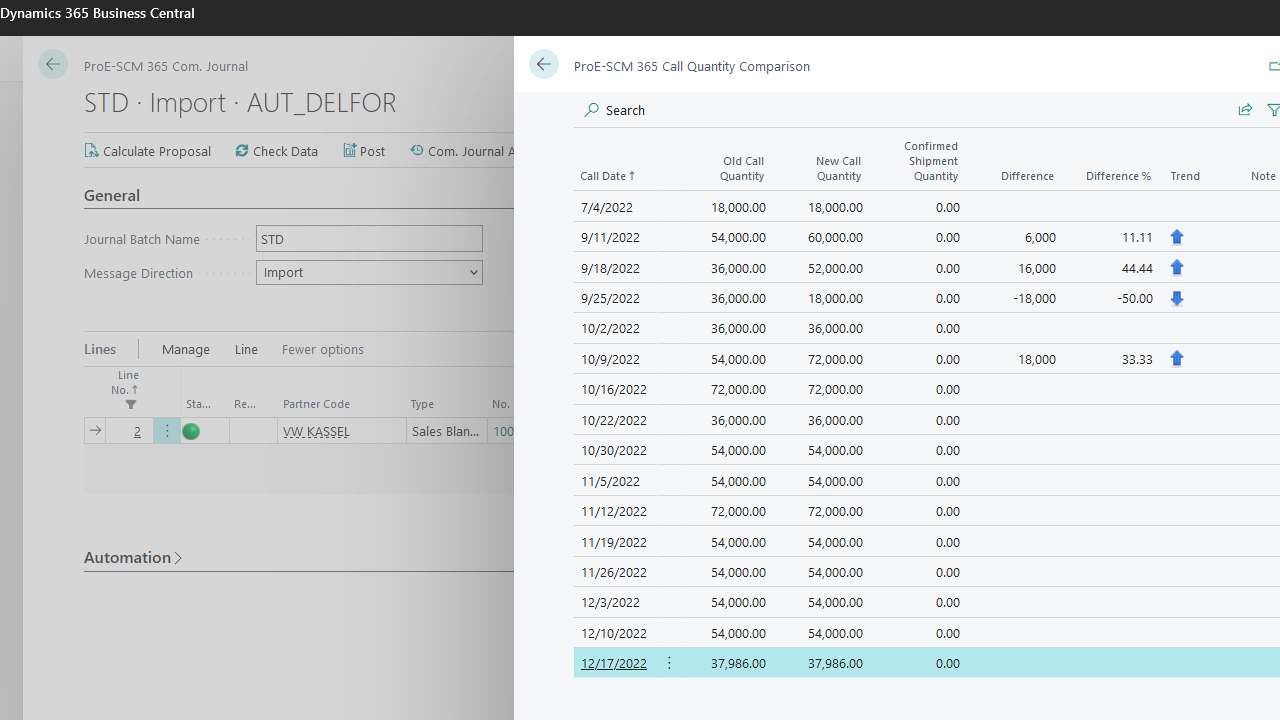

Import delivery schedules via a journal sheet

Updating framework agreements

Rounding of the call-off quantity

Date correction for deviations from the delivery schedule

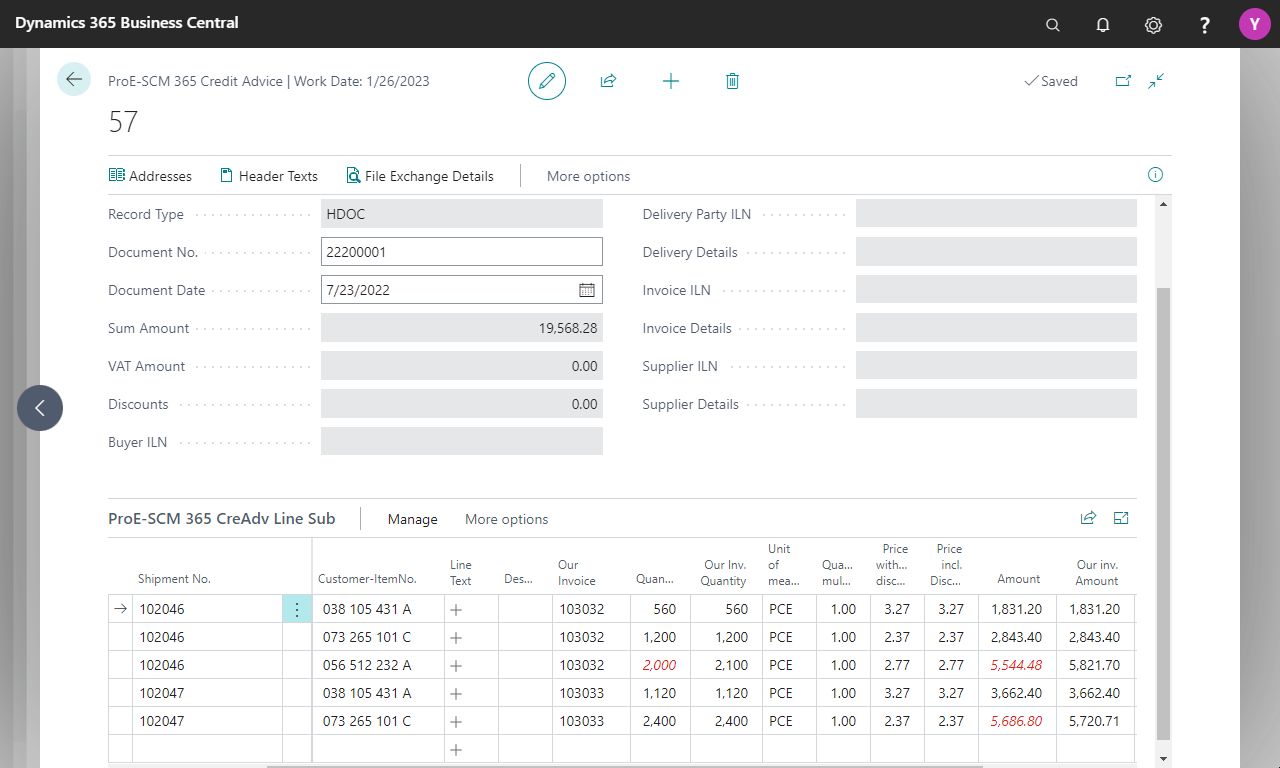

Export of posted sales invoices and credit memos

Restrictions for the VDA format

Guidelines for exporting such invoices

Reference to shipment invoice

Corrections to the progress number, manually or automatically

Progress number as the sum of shipments/transfer orders

Removing returned or unreceived shipments

Creating progress number provisions

Yes, the app is designed to meet the needs of JIT and JIS processes, enabling precise processing and delivery of scheduling agreements.

Tier-1 suppliers benefit from automated, secure, and fully integrated communication with their customers.

The app is built on preconfigured, certified interface formats that comply with the specifications of relevant standards. Updates can be applied regularly to quickly accommodate new requirements.

No. Customers who are not EDI-enabled can still be processed in the system as usual. However, for major players, EDI is often a necessity.

Volkswagen (VW), AUDI, SEAT, Skoda, BMW, Porsche, Daimler, Fiat, PSA, Lamborghini, Bentley, Toyota, Nissan, Chrysler, Rolls-Royce, Opel, Ford, MAN, SCANIA, Volvo, DAF, Valeo, Teclac, Veritas, Magna, Rehau, Faurecia, Axle Alliance, Bosch, Siemens, Elemica, and many more.

Yes. Yaveon 365 Automotive is fully integrated into the Microsoft ERP system.

The digital potential of the process industry – Beitrag öffnen

The digital potential of the process industry – Beitrag öffnen

We show you how the process industry can discover and unleash its greatest digital potential.

Success story: UBC – Beitrag öffnen

Success story: UBC – Beitrag öffnen

Read the reference report to find out how UBC automated its order processing and improved its own quality.

Success story: Kerbl – Beitrag öffnen

Success story: Kerbl – Beitrag öffnen

Read the reference report to find out how Albert Kerbl GmbH has managed to reduce costs, connect partners and much more.