Read the report to find out how Sanity introduced a validated ERP system in the public cloud and now works with automated processes!

Seamless tracking: Traceability along the entire supply chain

Find quickly: Identification by barcode or data matrix code

Centralized recording: Management of batches & serial numbers

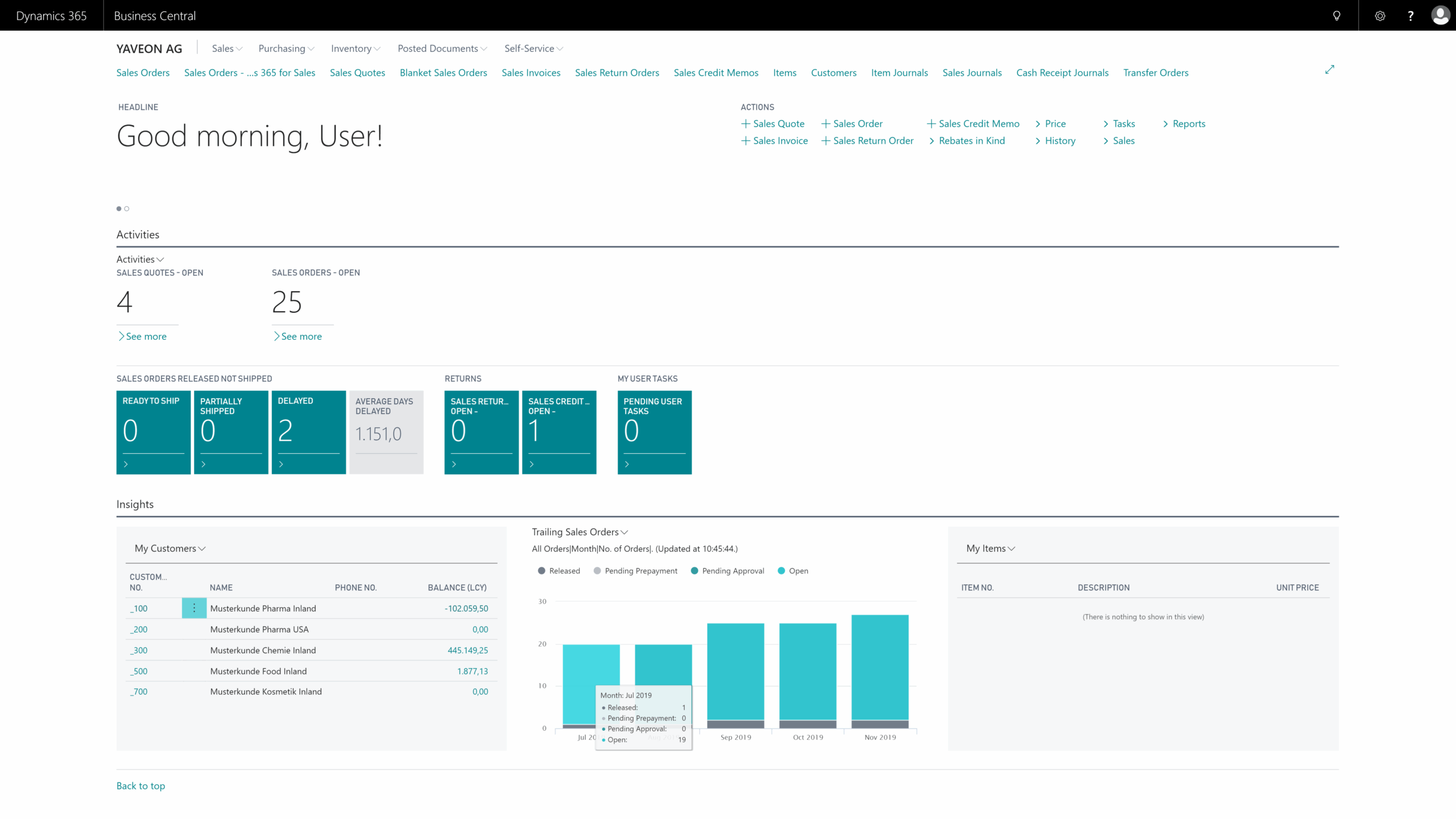

More than 750 companies worldwide rely on Yaveon

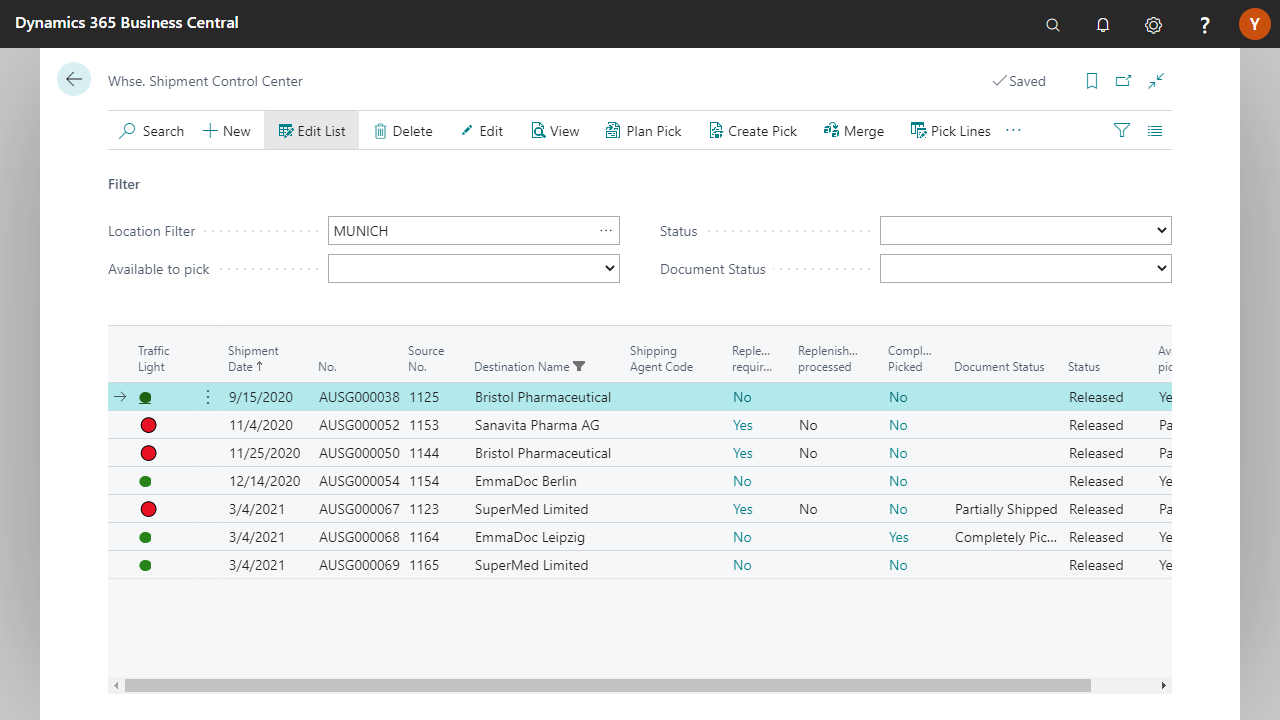

Assignment of traffic light colors according to defined rules

Rules can be defined individually per product and batch

Check at the time of booking that the batch meets the requirements

Traffic light status visible throughout

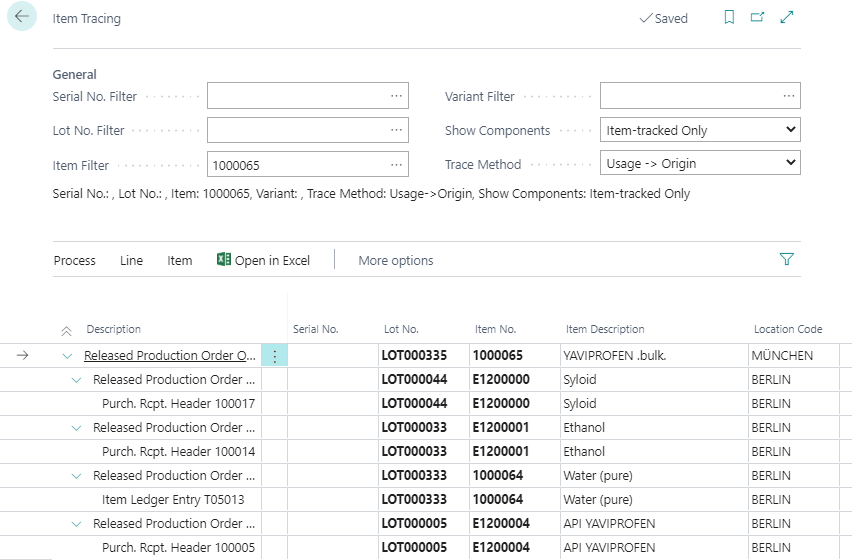

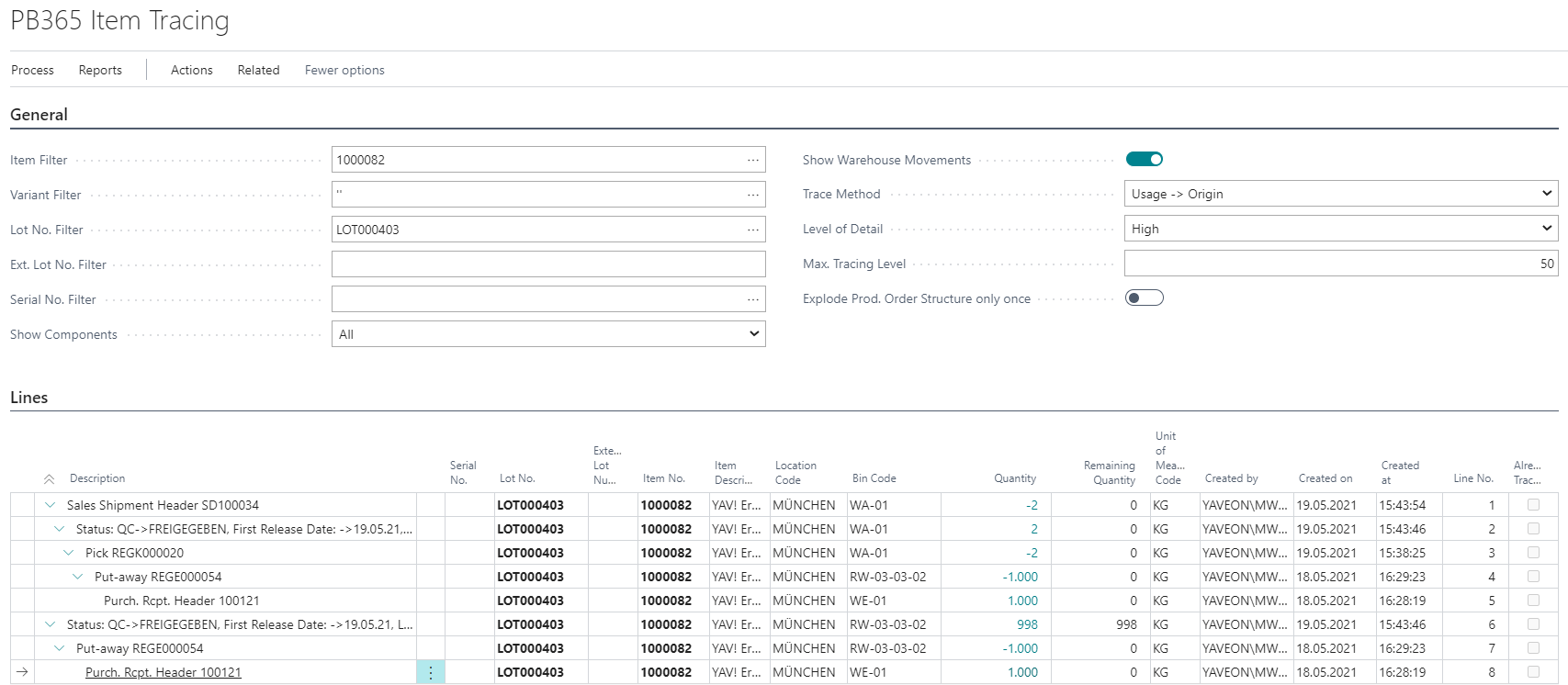

Tracking of all bookings via the article items

Recording changes to item tracking data

Processing of article tracking tasks

Warehouse and batch history & transfer posting between warehouses

Lot tracking across the entire supply chain

Batch number information Change

Batch splits and mergers

Identification of batches using bar & data matrix codes

Addition of additional data to the serial number

Changing existing serial number information

Change also possible for several serial numbers at the same time

Set up mandatory cause codes for change types

Booking rule groups, e.g. assembly consumption

Batch purity rules

Item tracking assignment rules

Batch number information Change rules

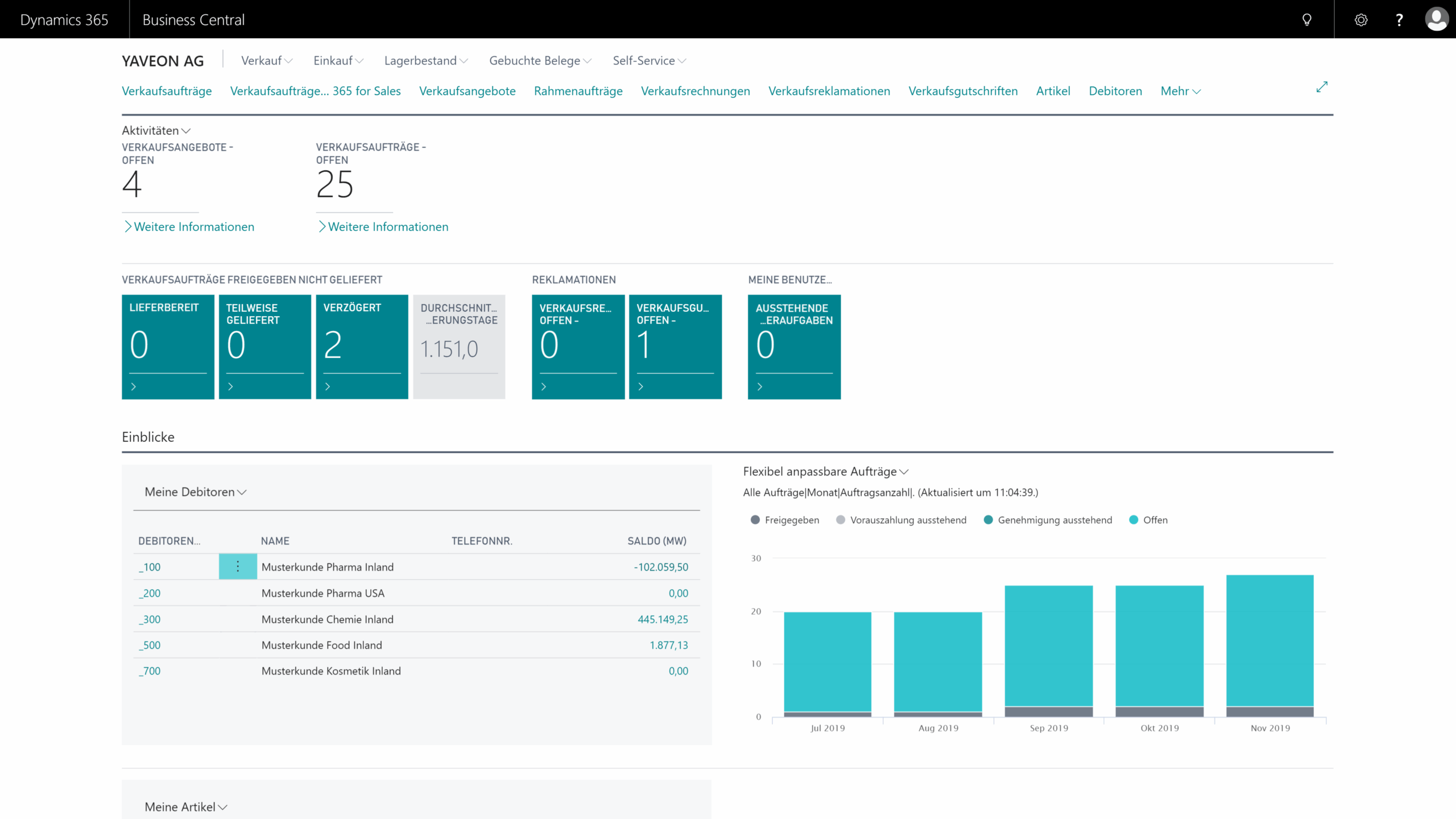

View current stock level

Simplified posting of inventory corrections

Order picking according to FEFO/FIFO

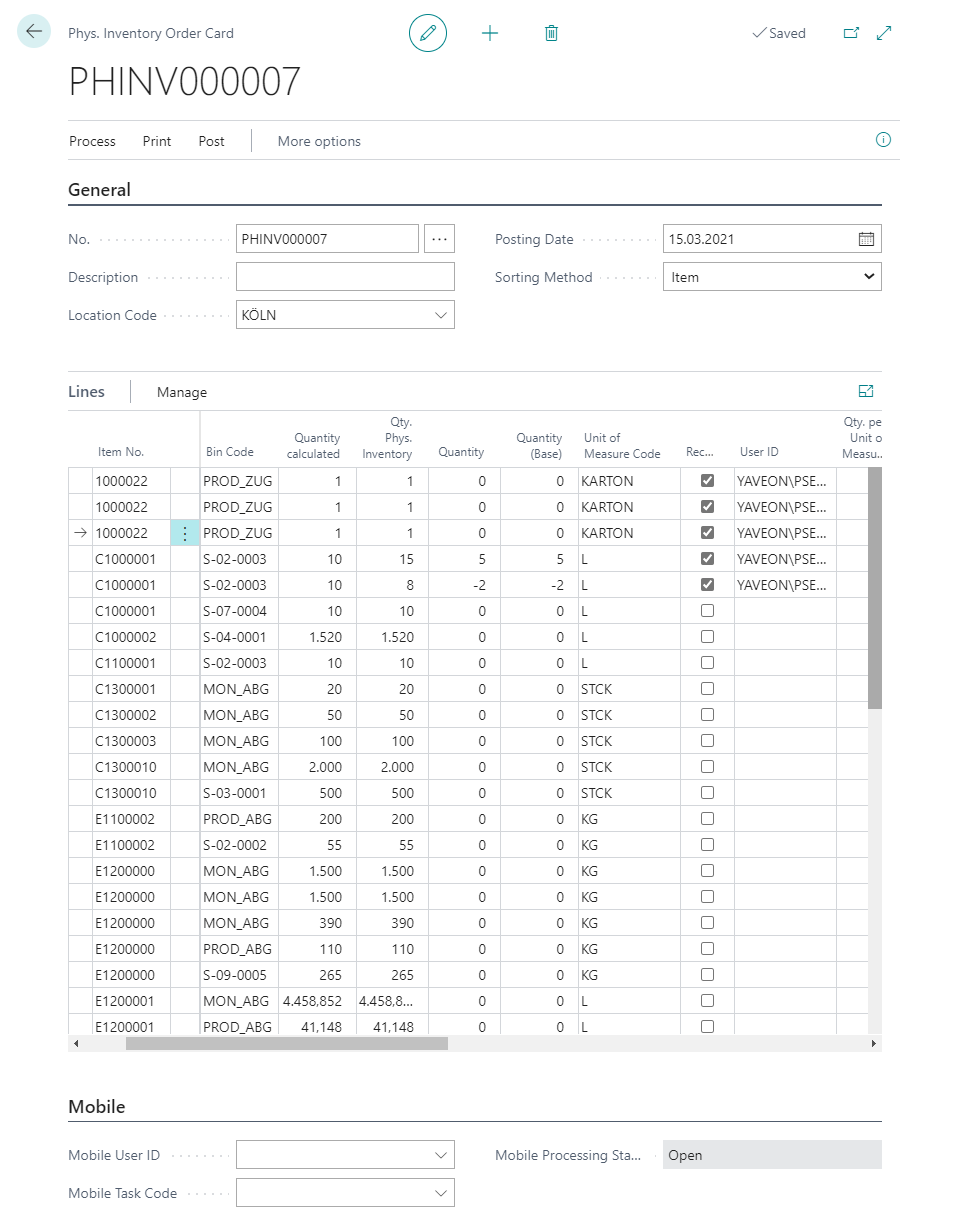

Inventory orders for the physical count of stock

Import of stocks

Transfer via stock import

Transfer via warehouse stock template

Error handling during import

The Lot Management App enables comprehensive lot tracking both backwards (to the supplier or origin) and forwards (to the customer or use). It automatically documents all batch-relevant movements in the system and displays them transparently. This allows supply chains and production routes to be traced seamlessly.

Yes, the app supports both the automatic assignment of batch numbers and the creation of individual batch labels. These can be configured according to company-specific requirements and provided with all the necessary information (e.g. expiration date, test results).

Thanks to the seamless documentation of all batch-related processes and traceability, the app helps to ensure compliance with legal requirements and industry-specific regulations. The set of rules also ensures process reliability by defining which batches may be used for which purpose and when. Yaveon 365 Lot Management supports the requirements for quality control, documentation obligations and recall management in particular.

Yes, the app is flexibly configurable and can be adapted to individual processes and requirements. For example, user-defined inspection features, your own release processes or specific intended uses can be stored and managed for each batch.

Yes, the app offers both forward and backward tracking. This not only makes it possible to trace where a batch comes from, but also where it was delivered to or in which products it was used.

The app enables inspection features, test results and release status to be linked directly to the respective batches. This supports targeted quality control and ensures that only tested and approved batches enter the further production or sales process.

Success story: Sanity – Beitrag öffnen

Success story: Sanity – Beitrag öffnen

Read the report to find out how Sanity introduced a validated ERP system in the public cloud and now works with automated processes!

Success story: Evident Ingredients – Beitrag öffnen

Success story: Evident Ingredients – Beitrag öffnen

Read the report to find out how evident ingredients has simplified batch management and how it is now securely ready for the future thanks to the Yaveon cloud solution.

Success story: Gustav Heess – Beitrag öffnen

Success story: Gustav Heess – Beitrag öffnen

Read the report to find out how gustav heess accelerated the ability to respond to the challenges of globalization and much more.